Unlock the full potential of your industrial applications with 럼투, a leading Chinese manufacturer renowned for our co-rotating twin screw plastic extruders. Our extensive experience and innovative technology cater to a broad range of industries, including plastics, chemicals, and food production.

Why Choose Rumtoo’s Twin Screw Extruders?

1. Versatile Applications:

Our twin screw extruders excel in various sectors such as plastics, chemicals, compounding, powder coatings, food industries, and wood-plastic composites. This versatility ensures you have the technology to push the boundaries of production and innovation.

2. Advanced Technical Characteristics:

- Modular Design: Our screws and barrels are designed based on a building block principle, allowing for easy customization and upgrades.

- High-Performance Series: Our RTM series includes models from 20mm to 200mm, each defined by different rotary speeds and torque classes to match your specific production needs.

- Enhanced Plasticizing and Compounding Units: Featuring closely intermeshed screw elements for superior self-wiping and interchangeability, our extruders ensure optimal performance and flexibility.

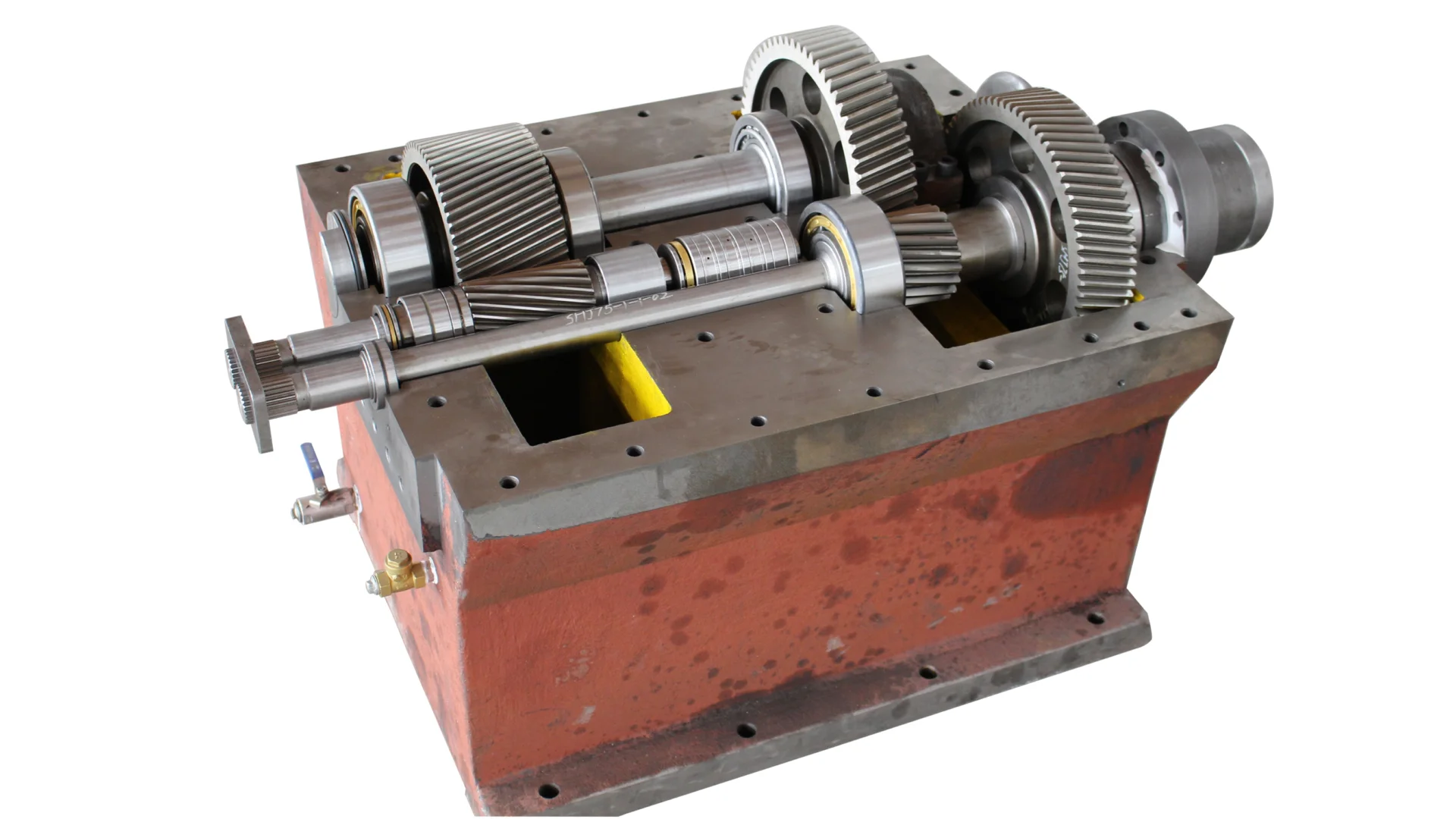

3. Exceptional Power Transmission System:

Experience reliability like never before with our state-of-the-art torque distribution system. Our extruders feature high precision grinding of hardened gear teeth, imported high-quality bearings, and an integrated lubrication system that collectively enhances durability and performance.

4. Premium Material Construction:

Rumtoo extruders are built with top-quality materials suited for various process requirements. Each unit is assembled on a robust welding base with special adjustment pads and stainless steel covers for optimal heat preservation.

5. Innovative Screen Changer Technology:

Choose from a variety of screen changers, including basket, plate-type, and continuous models, to keep your operations running smoothly without interruptions.

Product Specifications:

| 모델 | Diameter(mm) | Max. L/D | Speed(rpm) | Power(kw) | Output(kg/h) |

| RTM 52B | 51.4 | 68 | 600 | 55 | 150~250 |

| RTM 65B | 62.4 | 68 | 600 | 90 | 200~350 |

| RTM 75B | 71.4 | 68 | 600 | 132 | 400~600 |

| RTM 85B | 81 | 68 | 600 | 250 | 600~900 |

| RTM 95B | 93 | 68 | 600 | 315 | 800~1200 |

| RTM 120B | 116 | 68 | 500 | 450 | 1300~2000 |

| RTM 135B | 133 | 68 | 500 | 900 | 2500~4000 |

결론:

With over 20 years of specialized expertise in screw design and manufacturing, 럼투 stands at the forefront of the extrusion technology industry. Whether you’re looking to enhance your production in the plastic, chemical, or food sectors, our co-rotating twin screw extruders are engineered to elevate your operational capabilities to new heights.

Inquire now

Ready to revolutionize your production processes? Contact Rumtoo today to learn more about our twin screw extruders and how we can tailor them to meet your specific industry needs.