맞춤형 제작을 통해 플라스틱 재활용의 효율성을 극대화하는 방법은 무엇인가?

Customizing plastic recycling machines is crucial for enhancing the efficiency of recycling operations. Here’s how customization can transform your recycling process:

- Saving Energy and Space: Custom layouts allow for optimized use of space within your facility, ensuring that machinery is arranged to minimize energy use and maximize throughput. For instance, machines can be designed in L, I, or U shapes to fit into existing factory layouts, reducing the need for extensive modifications or expansions. This spatial efficiency directly translates into energy savings, as machines can operate closer to their optimal capacity without the energy wastage associated with poor layout planning.

- Tailored to Specific Plastic Types: Not all plastics are the same; different types require different processing methods. Customization allows for the integration of specific tools like shredders, extruders, or pelletizers that are best suited for the types of plastic you typically handle, whether it’s PET, HDPE, LDPE, or others. This specificity ensures higher recovery rates and less contamination, which is vital for producing high-quality recycled materials.

- Increased Flexibility and Simplified Operations: With custom machines, you can adapt to variable incoming waste streams more easily. Features like adjustable cutting blades or modular components mean that as your waste stream changes, your machinery can too, without needing a complete overhaul. This adaptability not only simplifies operations but also reduces downtime, enhancing overall productivity.

- Improved Quality of Recycled Plastic: Customization can include high-precision control systems or specialized filtration systems that ensure the purity and quality of the output. By focusing on the quality of recycled pellets or flakes, you can cater to industries that demand high-grade recycled materials, thereby expanding your market.

- 순환 경제 지원: By making recycling more economically viable through efficiency, customization directly contributes to the circular economy. It encourages more businesses to engage in recycling, reducing landfill waste and the demand for virgin plastics.

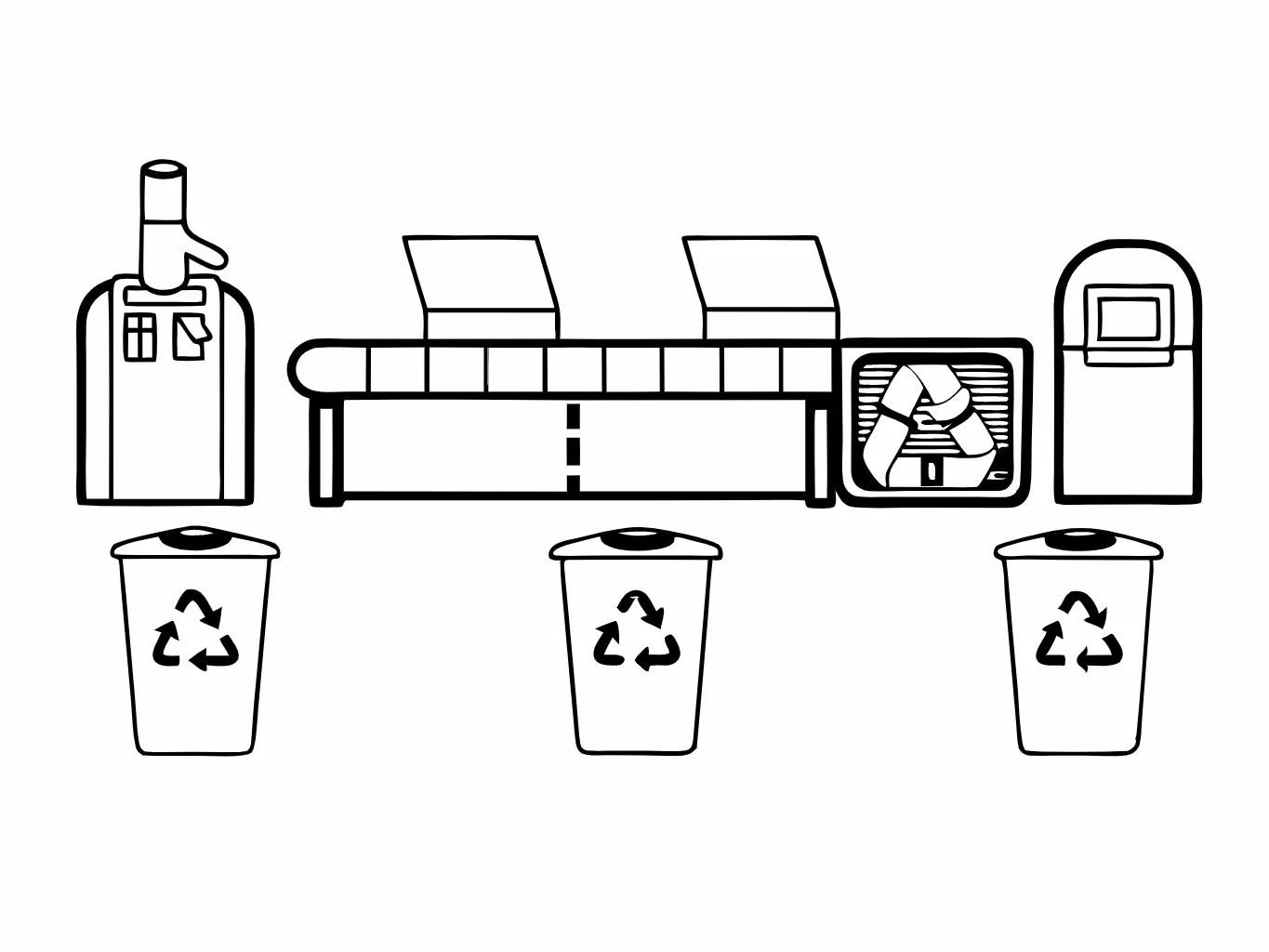

Designing Custom Layouts for Plastic Recycling Machines

When considering the layout of your recycling facility:

- Assess Your Space: Evaluate the size, shape, and constraints of your facility. Custom layouts from manufacturers like Rumtoo can be tailored to fit almost any space, ensuring that each machine is positioned for optimal flow and minimal energy use.

- Choose the Right Shape: Decide between L, I, or U layouts based on your workflow. An L shape might be ideal for smaller spaces where materials need to move back and forth, while a U shape can facilitate a continuous flow in larger areas.

- Integrate Specific Needs: Whether it’s a cutter compactor for bulkier plastics or a hopper feeder for consistent input, integrating specific machinery types into your layout can drastically improve efficiency.

- Future-Proofing: As your operations grow or change, having machines with flexible layouts ensures they can evolve with your business needs, avoiding the need for significant capital outlays on new machinery.

Why Opt for Customization?

- 경제적 이익: Custom machines can lead to a quicker return on investment due to their efficiency and adaptability to your specific waste profile.

- 환경 영향: By optimizing the recycling process, you reduce waste and energy consumption, lowering your carbon footprint.

- Market Competitiveness: Offering high-quality recycled products can open new market segments, from packaging to manufacturing, where recycled content is increasingly valued.

결론

Customizing your 플라스틱 재활용 기계 layout isn’t just about fitting equipment into your space; it’s about redefining how you handle plastic waste to make every part of the process more effective. By focusing on how to customize, what to consider, and why it matters, businesses can significantly enhance their recycling operations. For detailed insights or to discuss your specific needs, feel free to 문의하기 for further details on machine layout customization.

This approach not only aligns with sustainability goals but also positions your business as a leader in efficient, high-quality plastic recycling.