One of the more challenging materials to cut efficiently is large pieces of elastic plastics and rubbers that are highly resistant to rapid rotary granulator machines. While double-shaft shredders are ideal for this task, they are more costly, and the maintenance required is more time-consuming.

To streamline your operation in handling this type of material, we introduce our three-clawed single-shaft shredder machines designed specifically to cut materials like rubber tires, silicone, and large pieces of TPE, EVA, and other rubber-like plastics. This specific model starts from a capacity of 1000 kg/h and ranges up to 5000 kg/h.

작동 원리

Based on our experience working with numerous recycling plants, single-shaft plastic shredder machines offer the necessary durability and the convenience of straightforward maintenance. As with most single-shaft shredders on the market today, this machine uses a hydraulic-assisted drawer to push the rubber or elastic plastic material against a slow-rotating rotor.

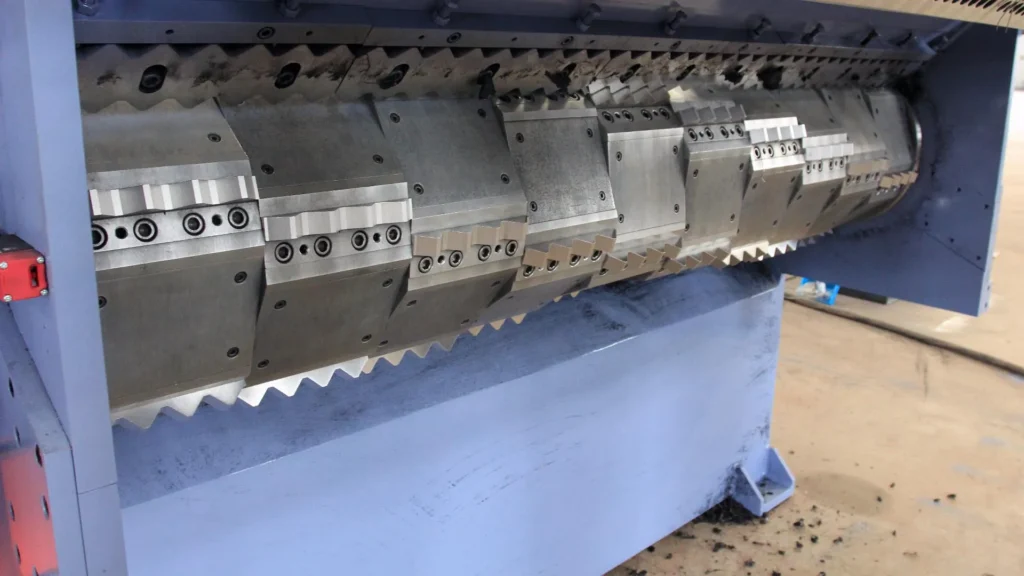

This rotor is engineered specifically with 3-clawed blades attached in a staggered array to grip large pieces of elastic materials. There are also stationary blades attached within the cutting chamber. When the rotor spins, the rotary blades make contact with the stationary blades, resulting in the material being cut.

A filter screen at the bottom of this shredder allows material that is small enough to pass through while holding larger pieces within the cutting chamber for continuous cutting. Once this material becomes small enough, it can pass through.

특징

- Highly durable hooks – The three-clawed blades are optimized for shredding geometry and are made with SKD11 or D2 equivalent steel that is highly durable against wear.

- Two-part housing – Our two-part design allows the entire rotary shaft to be conveniently removed for maintenance.

- Superior sealing – The bearings on this machine are quadruple-sealed, preventing leaks even for liquids.

- Shock absorbing – Our enhanced shock absorption system efficiently protects the hydraulics from overloading.

- Hydraulic drive – Our shredder uses a specially designed hydraulic drive offering optimal torque and performance, performing exceptionally well in extreme conditions.

기술 사양

| 모델 | 모터 파워 | 샤프트 직경 | Rotary Speed | 용량 |

|---|---|---|---|---|

| BS-1000 | 45 kW | ⌀450 mm | 55 rpm | 1000 kg/h |

| BS-2000 | 110 kW | ⌀500 mm | 45 rpm | 3000 kg/h |

| BS-3000 | 2x 110 kW | ⌀550 mm | 40 rpm | 5000 kg/h |

*CE certification available. *Larger, more powerful models available upon request.

추가 이미지

보증

모든 재활용 기계에는 1년 제한 보증이 제공됩니다.

지금 문의하세요

최신 가격과 리드타임을 알아보려면 아래 양식을 사용하여 메시지를 보내주세요.