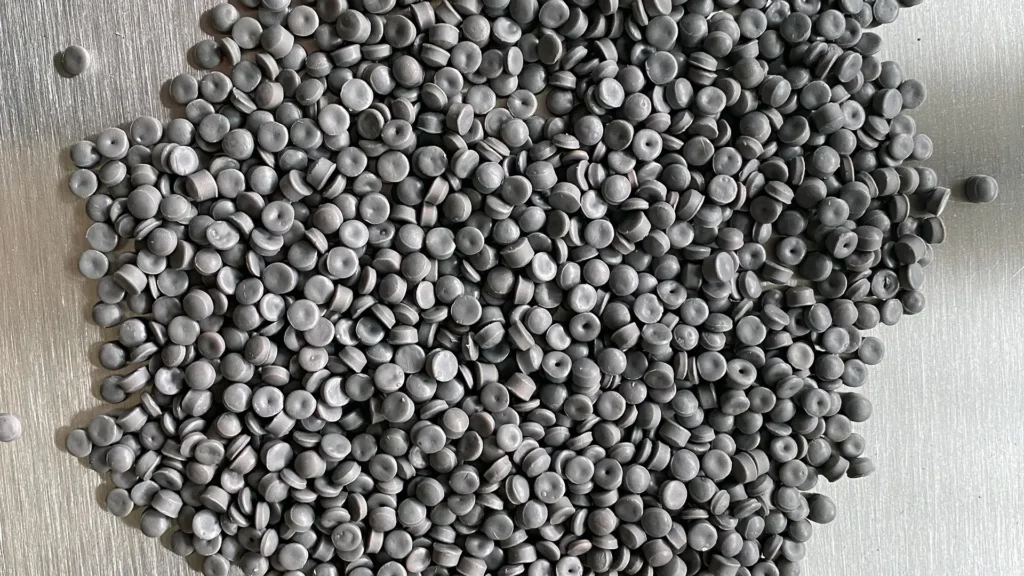

이 2단계 HDPE 플레이크 펠렛화 시스템은 두 세트의 단축 압출기로 구성되어 있으며, 공급, 가소화, 펠렛화 기능을 단일 단계로 통합합니다. 이 펠렛화 기계에서 생산되는 최종 제품은 고품질 펠렛/과립(아래 추가 이미지 참조)으로, 플라스틱 사출기 또는 기타 용도에 직접 투입할 수 있습니다.

작동 원리

급송: The flakes are fed into the extruders by screw conveyors that are managed by VFD. The VFD feeding system halts automatically when the electric current in the extruder is elevated and will only resume when the electrical current returns to standard parameters.

가소화 및 탈기: A specialized single-screw extruder delicately melts the pre-compacted material. The plastic scraps are melted and plasticized in the first-stage extruder and then extruded by the second-stage extruder. With this “dual-zone” vacuum degassing system, volatiles such as low molecular weight substances and moisture are effectively removed. This results in more consistent final products.

용융 여과: This system utilizes segmented filtration. The first extruder is tasked with removing coarse contaminants via pre-filtration. A high mesh filter is then applied to the second extruder to eliminate fine particles. This lowers the frequency for changing filtration media and sieves.

펠릿화: To convert the extruded plastic into granules, a standard die-face water ring pelletizing system is employed. Once the pellets are formed, an advanced dewatering vibration sieve is paired with a horizontal-type centrifugal dewatering machine to dry the pellets for storage.

기술 사양

| 기계 크기 | Motor Power (Compactor) | 나사 직경(mm) | 엘/디 | Motor Power (Extruder) | 처리량(kg/h) |

|---|---|---|---|---|---|

| SJ80 | 37 kW | 80 | 36 | 45/55 kW | 160-220 |

| 에스제이100 | 55kW | 100 | 36 | 90/110 kW | 300-380 |

| SJ120 | 90 kW | 120 | 36 | 132 kW | 450-480 |

| SJ140 | 110kW | 140 | 36 | 160/185 kW | 500-650 |

| SJ160 | 132 kW | 160 | 34 | 220/250 kW | 800-1000 |

| SJ180 | 315 kW | 180 | 34 | 315 kW | 1000-1200 |

추가 이미지