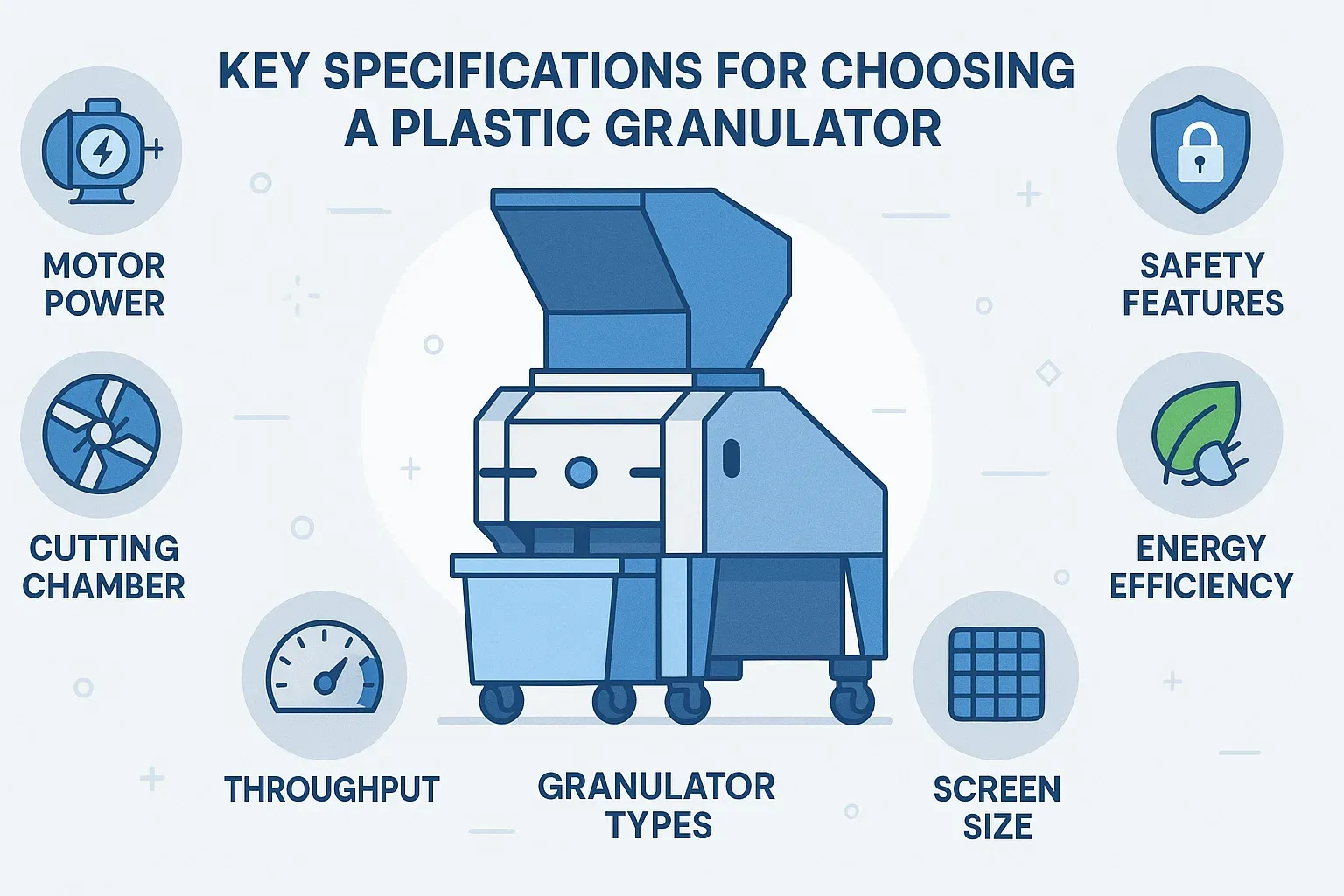

When sourcing a 플라스틱 분쇄기 for your manufacturing or recycling operations, selecting the right equipment is crucial to ensure efficiency, safety, and cost-effectiveness. This comprehensive guide outlines the top 10 technical specifications industrial buyers, engineers, and technical personnel should consider before making a purchase.

-

Granulator Type

Plastic granulators come in various configurations, each suited for specific applications:

- 중앙 분쇄기: Ideal for processing large volumes of waste from injection molding, extrusion, or blow molding lines.

- 프레스 옆 조립기: Designed for in-line recycling of sprues and rejects directly at the molding machine.

- Roll-Feed Granulators: Best for processing films and thin-walled materials.

- 저속 분쇄기: Suitable for handling delicate materials with minimal noise and dust generation.

Selecting the appropriate granulator type ensures optimal performance and longevity of the equipment.

-

Motor Power and Capacity

The motor power, typically measured in horsepower, determines the granulator’s capacity to process materials:

- Small Granulators: Range from 5 HP to 15 HP, suitable for low to medium throughput.

- Medium Granulators: Range from 20 HP to 50 HP, designed for higher capacity needs.

- Large Granulators: Exceed 50 HP, capable of handling large volumes of tough materials.

Ensure the motor power aligns with your processing requirements to maintain efficiency and prevent overloading.

-

Cutting Chamber Design

The design of the cutting chamber affects the granulator’s efficiency and the quality of the output:

- Rotor and Blade Configuration: Options include open rotor with bed knives, closed rotor, and V-shaped rotor designs.

- Knife Material: High-carbon, high-chromium steel knives, such as D2 or SKD11, offer durability and longer service life.

- 조정 가능성: Hydraulic-assisted access to the cutting chamber facilitates easy maintenance and blade adjustments.

A well-designed cutting chamber enhances cutting efficiency and reduces maintenance downtime.

-

Screen Size and Mesh Options

The screen size determines the granule size and affects the granulation process:

- Standard Screen Sizes: Commonly range from 10mm to 100mm.

- Customizable Mesh: Allows for tailoring the granule size to specific requirements.

- Screen Material: Durable materials like stainless steel can withstand wear and corrosion.

Selecting the appropriate screen size ensures consistent granule quality and meets downstream processing needs.

-

Throughput Capacity

Throughput capacity, measured in kilograms per hour, indicates the granulator’s processing capability:

- Low Throughput: Suitable for small-scale operations with throughput requirements of up to 500 kg/h.

- Medium Throughput: Ideal for medium-scale operations requiring 500 kg/h to 1,000 kg/h.

- 높은 처리량: Designed for large-scale operations with needs exceeding 1,000 kg/h.

Matching the granulator’s throughput capacity with your production volume ensures operational efficiency.

-

에너지 효율

Energy consumption is a significant operational cost:

- Variable Speed Drives: Allow for adjusting motor speed based on load, improving energy efficiency.

- 고효율 모터: Consume less power while delivering the required performance.

- Energy Recovery Systems: Capture and reuse energy within the system to reduce overall consumption.

Opting for energy-efficient granulators can lead to substantial cost savings over time.

-

Noise and Vibration Levels

Excessive noise and vibration can impact the work environment and equipment longevity:

- 저속 분쇄기: Typically produce less noise and vibration.

- Sound Enclosures: Enclose the granulator to dampen noise levels.

- Vibration Dampening Systems: Reduce vibrations, protecting both the equipment and the facility.

Selecting equipment with manageable noise and vibration levels contributes to a safer and more comfortable workplace.

-

안전 기능

Ensuring operator safety is paramount:

- Emergency Stop Mechanisms: Quickly halts operation in case of emergencies.

- 안전 연동 장치: Prevent operation when access doors are open.

- Guarding and Shields: Protect operators from moving parts.

- Compliance with Standards: Ensure adherence to local and international safety regulations.

Prioritizing safety features reduces the risk of accidents and enhances compliance with safety standards.

-

Maintenance and Serviceability

Ease of maintenance affects downtime and operational continuity:

- Tool-Free Access: Facilitates quick and easy maintenance tasks.

- Modular Components: Simplify replacement and servicing of parts.

- Availability of Spare Parts: Ensures quick repairs and minimal downtime.

Choosing granulators with user-friendly maintenance features can lead to reduced operational interruptions.

-

Compliance and Certifications

Ensuring the granulator meets industry standards is essential:

- CE 인증: Indicates compliance with European Union safety, health, and environmental requirements.

- ISO Standards: Demonstrates adherence to international quality management standards.

- Local Regulatory Compliance: Meets specific regional or national regulations.

Verifying certifications ensures the equipment’s reliability and compliance with legal requirements.

결론

Selecting the right plastic granulator involves careful consideration of various technical specifications. By evaluating factors such as granulator type, motor power, cutting chamber design, and safety features, industrial buyers can make informed decisions that align with their operational needs and regulatory requirements.

By understanding these specifications and utilizing available resources, you can ensure the selection of a plastic granulator that enhances your production efficiency and meets industry standards.