In the world of plastic recycling, efficiency is key. As recycling plants handle large volumes of compacted HDPE and PET bottles, the need for an effective solution to break apart these bales becomes paramount. Enter the vertical debaler machine—a powerful, automated solution designed to streamline the recycling process, reduce manual labor, and enhance overall productivity. This article explores the mechanics, benefits, and technical specifications of this innovative machine, making it an indispensable asset for any plastic recycling facility.

Vertical Debaler Machine: The Game-Changer in Plastic Recycling

The Need for a Vertical Debaler Machine

Recycling plants often receive compacted bales of rigid plastics like HDPE and PET bottles. These bales are too dense to be processed directly, making it necessary to break them apart before recycling. Traditionally, this task was done manually—a time-consuming and labor-intensive process. The vertical debaler machine automates this step, ensuring that plastic bottles are efficiently loosened and prepared for further processing. By integrating this machine into your recycling line, you can significantly reduce operational costs and increase throughput.

How the Vertical Debaler Machine Works

그만큼 vertical debaler machine is designed for simplicity and efficiency. Unlike horizontal debalers, which may require more manual intervention, the vertical model comes with a long feeding belt conveyor capable of holding up to five bales at once. Here’s a step-by-step breakdown of how it operates:

- Loading: Bales are loaded onto the conveyor belt using a forklift. The conveyor moves the bales forward into the machine.

- Unbinding: The wires or straps holding the bales together are cut and removed manually.

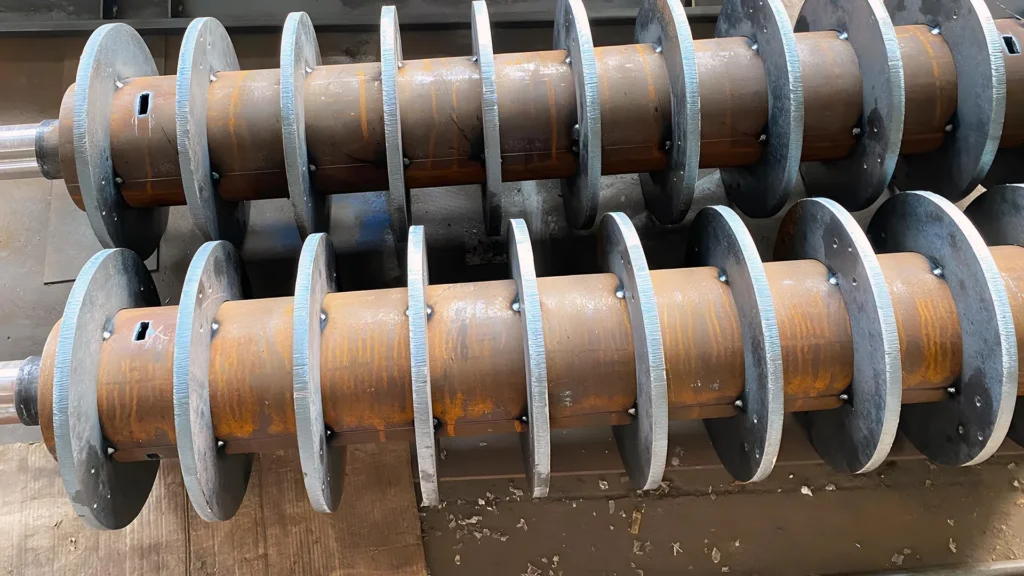

- Debaling Process: The bales are fed into the machine, where two vertically positioned, opposite-rotating rotors with disks scatter and loosen the compacted plastic.

- 산출: The freed plastic flows onto a lower conveyor, ready to be fed into further recycling processes.

This automated process not only speeds up the initial phase of recycling but also frees up workers to focus on other tasks, ultimately increasing plant efficiency.

pet bottle bales

Advantages of Using a Vertical Debaler Machine

투자하다 vertical debaler machine offers numerous benefits for recycling facilities:

- 효율성 향상: Automating the debaling process reduces the time needed to prepare plastic for recycling.

- Labor Savings: With fewer workers required to manually break apart bales, you can lower operational costs.

- Higher Throughput: The ability to load multiple bales at once allows for continuous operation, improving overall productivity.

- 다재: While primarily designed for rigid plastics like HDPE and PET, larger and more powerful models are available to handle varying bale sizes.

기술 사양

When selecting a vertical debaler machine, understanding its technical specifications is crucial:

- 메인 모터 전력: 7.5 kW x 2

- Feeder Dimension: 1550mm x 1850mm

- Certification: CE certification available

- 사용자 정의: Larger, more powerful models can be requested to suit specific needs.

It’s important to note that while the vertical debaler is highly effective for rigid plastics, it is not suitable for plastic film. For facilities dealing with plastic film, a single-shaft plastic shredder is recommended to avoid machine damage.

추가 이미지

결론

그만큼 vertical debaler machine is an essential tool for modern plastic recycling plants, offering a perfect blend of automation, efficiency, and cost-effectiveness. By incorporating this machine into your recycling process, you can drastically reduce manual labor, streamline operations, and ultimately enhance your plant’s output.

For facilities looking to upgrade their equipment and improve recycling efficiency, the vertical debaler machine is an investment that pays for itself in increased productivity and reduced operational costs.

지금 문의하세요

최신 가격과 리드타임을 알아보려면 아래 양식을 사용하여 메시지를 보내주세요.