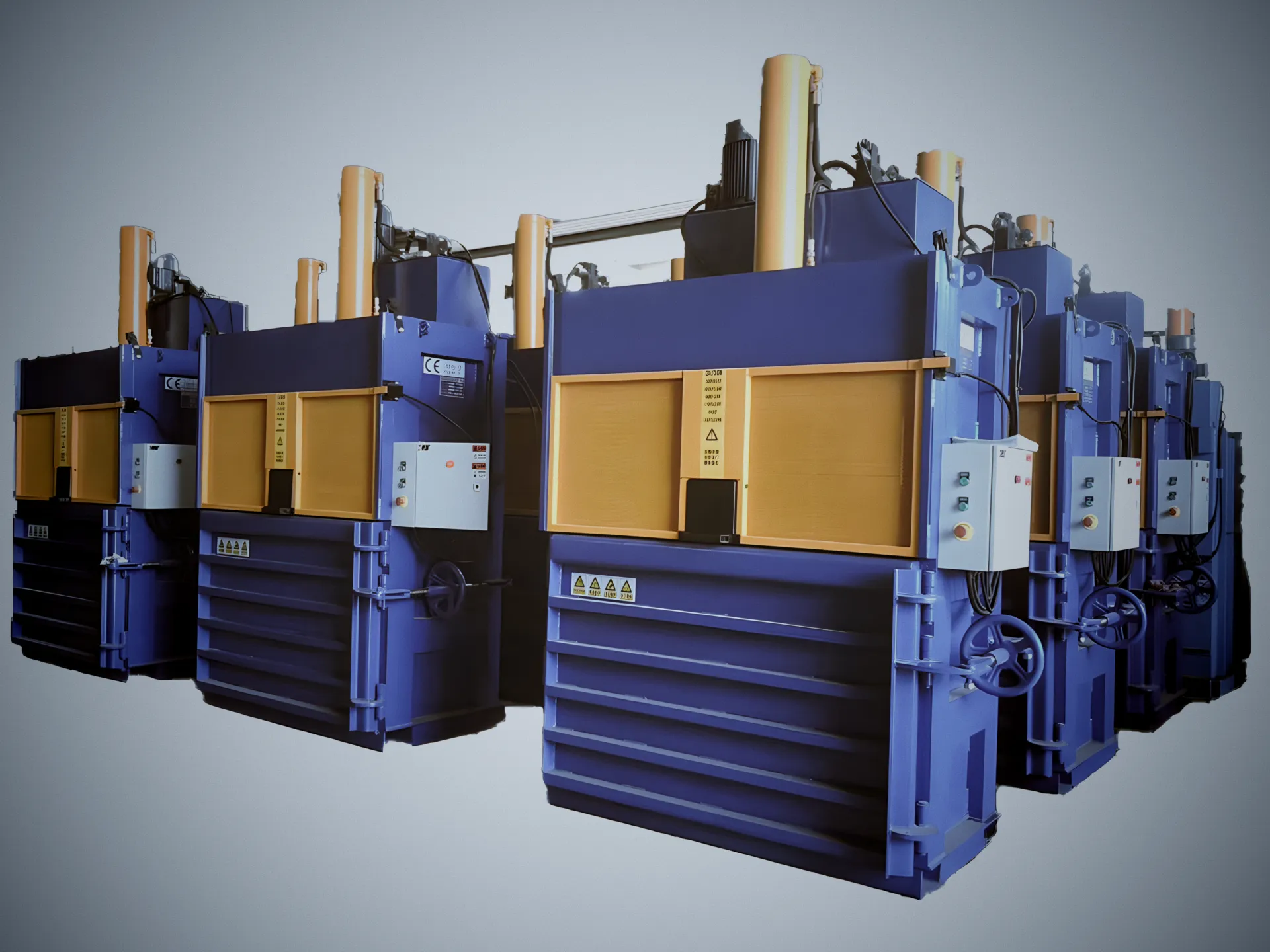

The Manual Baling Machine is a practical and economical solution for condensing loose materials, including waste paper, plastic film, and PET bottles. It reduces material volume, making transport easier and more cost-efficient. This versatile machine can be operated manually or through PLC control, driven by hydraulic pressure. With customizable options, it adapts to varied operational needs.

Primary Use and Materials Handled

The machine is designed to compress loose materials for easier handling and transport, handling a range of materials such as waste paper, plastic films, and PET bottles. This flexibility makes it ideal for recycling plants, packaging facilities, and waste disposal centers.

Efficient Operation: Manual or PLC-Controlled

This baler offers both manual and PLC-controlled operation, driven by hydraulic pressure for efficient compression. Its special press head ensures precision in operation, maintaining consistent bale quality.

Customization for Diverse Needs

The baler allows customization of the compression chamber and package block size, ensuring it meets the specific requirements of various users. This adaptability makes it suitable for small facilities or larger recycling plants.

Key Advantages

- Efficiency and Cost-Savings: By significantly reducing the material volume, the machine minimizes transportation costs. It features good rigidity, toughness, and stability, making it energy-efficient and cost-effective for long-term use.

- Versatile Applications: The baler is suitable for various industries, including waste paper factories, recycling companies, and more.

- Durable Design: Made from high-quality steel, the machine ensures long-term durability without high investment costs.

- Ease of Operation: The user-friendly design simplifies operation and maintenance, ensuring smooth workflows in recycling environments.

Working Principle

The machine compresses loose materials and secures them with a special packaging belt. Some models feature a spring-loaded compressing lever, which aids in forming bales more effectively.

Applications Across Industries

This manual baling machine finds applications in packaging plants, small waste disposal centers, and even paper mills, thanks to its easy installation and operation.

Additional Features

- Some models come with a ratchet pressing mechanism, increasing compression capacity and enhancing safety.

- Certain designs offer a second door for easy bale removal, streamlining the overall process.

Conclusion

The Manual Baling Machine is a valuable asset for recycling and waste management operations, offering a balance of efficiency, cost-effectiveness, and ease of use. Whether in a small facility or a larger recycling center, this baler meets diverse needs with reliable performance.

| Specification | Model | RTM-300LE | RTM-400LE | RTM-500LE | RTM-600LE |

|---|---|---|---|---|---|

| Pressure | 30tons | 40tons | 50tons | 60tons | |

| Feed opening size (L*H) | 1100*500mm | 1200*500mm | 1500*500mm | 1800*500mm | |

| Bale size (L*W*H) | 1100*700*(500-900)mm | 1200*800*(600-1000)mm | 1500*760*(600-1000)mm | 1800*1000*(350-1050)mm | |

| Power | 5.5kw | 7.5kw | 7.5kw | 11kw |

Inquire Now

To get the latest prices and lead times, send us a message using the form below.