System mielenia mikronizacyjnego

The Micronize Grinding System is a high-performance solution designed for pulverizing various plastic materials into fine powder form, catering to a wide range of industrial applications. This system is engineered for efficiency, durability, and the production of consistent, high-quality powder.

Image Gallery

Demonstracja wideo

Functions

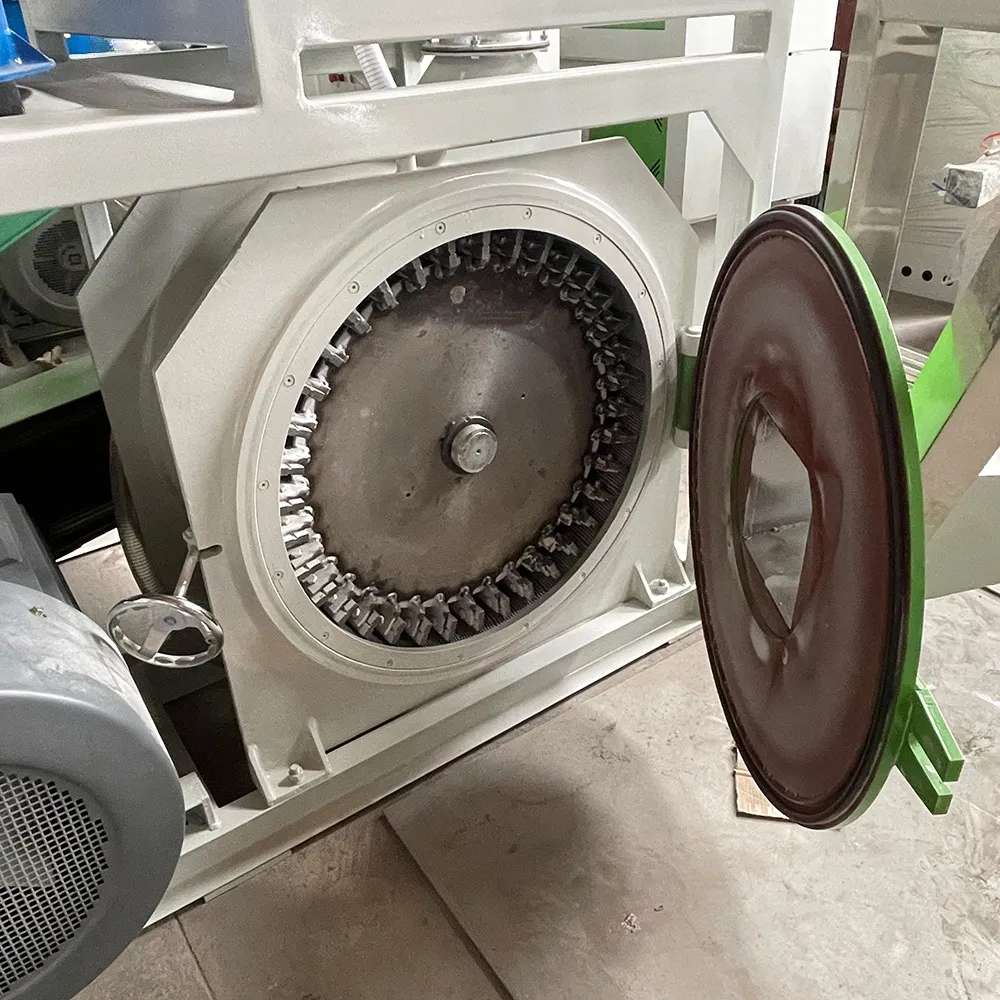

The primary function of the Micronize Grinding System is to grind and process plastic materials, transforming granules and waste into fine powder. This is typically achieved through disc pulverizers that utilize the gap between two grinding discs to mill the material. The system is capable of processing a variety of plastics, including:

It is also an indispensable tool for recycling plastic waste, allowing manufacturers to manage excess material and reduce production costs.

Zalety

High Throughput Rates

Designed for excellent performance and maximum efficiency, enabling large-scale production.

Low Energy Consumption

Engineered to save energy without compromising the quality of the grinding process.

Minimal Thermal Material Stress

Ensures the integrity of the material during the grinding process.

Adjustable Grinding Mesh Sizes

Allows for customization of the output to meet specific requirements.

Łatwa konserwacja

Features a user-friendly design that simplifies upkeep and reduces downtime.

Longer Disc Life

Utilizes robust materials and design to extend the lifespan of critical components, reducing replacement costs.

Quick Disc Adjustment

Streamlines the process of maintaining and adjusting the grinding mechanism.

Cost-Effective Operation

Provides an efficient and economical solution for plastic pulverizing needs.

Przyjazny dla środowiska

Operates without causing pollution, supporting sustainable manufacturing practices.

Jakości

Zaawansowana technologia

Incorporates the latest technological advancements and features inspired by international standards.

Robust Materials

Constructed from durable materials like low-carbon steel, ensuring a long service life and minimal maintenance.

Adjustable Blades

Equipped with adjustable rotor blades (static and rotating) to ensure efficient grinding and achieve the desired particle size.

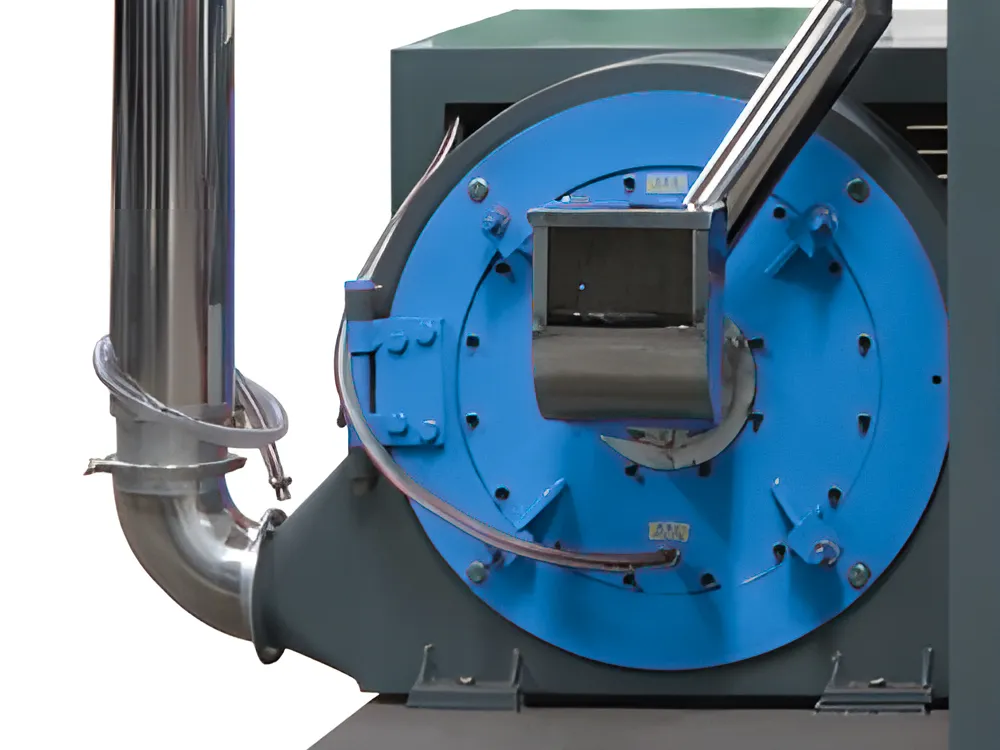

Cooling Systems

Many models include air and water cooling systems to prevent overheating, maintain stable performance, and extend the equipment’s lifespan.

Dust Removal Systems

Advanced models are equipped with dust removal systems to minimize pollution and maintain a clean working environment.

Enhanced Performance

Offers improved performance compared to similar equipment, meeting the practical needs of users while promoting cost-effective operations.

Specyfikacja

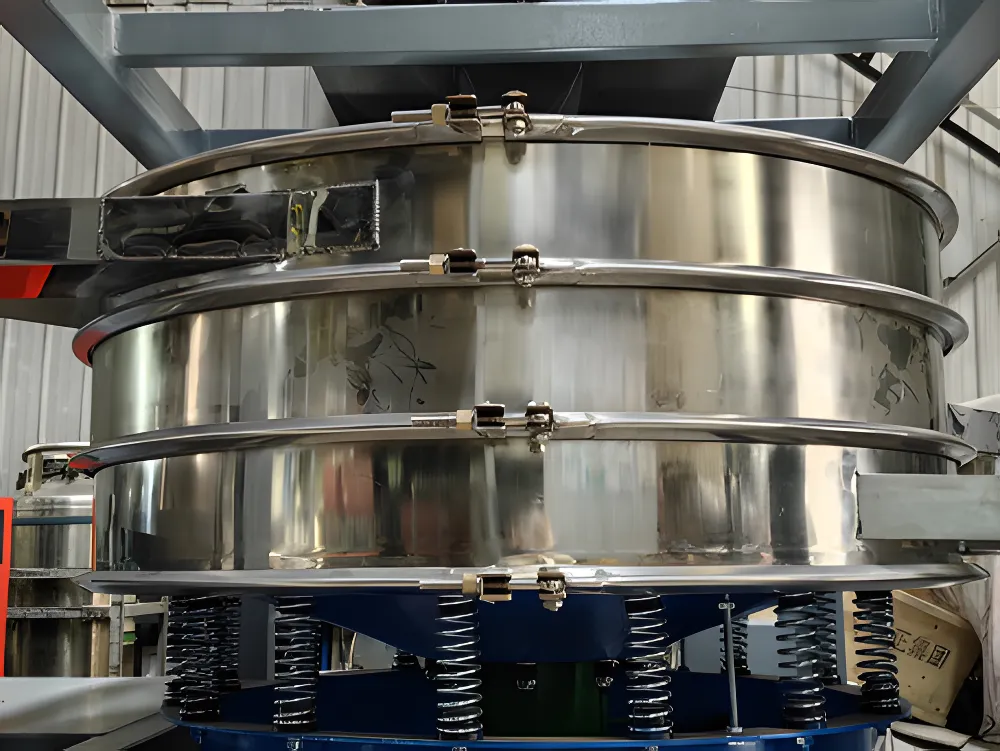

| Model | Moc | Średnica obrotowa | Moc wentylatora | Liczba ostrzy | Średnica sita wibracyjnego | Produkcja | Waga sprzętu |

|---|---|---|---|---|---|---|---|

| RTMPF-500 | 2,2 kW | 500 mm | 4 kW | 12+24 | 800 mm | 150-200kg/godz. | 1500 kg |

| RTMPF-600 | 4 kW | 600 mm | 5,5 kW | 13+26 | 1000 mm | 200-450kg/godz. | 2000 kg |

| RTMPF-800 | 4 kW | 800 mm | 11 kW | 15+32 | 1200 mm | 500-800kg/godz. | 2800 kg |