Standard Plastic Granulators

In the rapidly growing field of plastic recycling, Standard Plastic Granulators have become indispensable for transforming plastic waste into reusable materials, playing a critical role in sustainability and resource efficiency.

What is a Standard Plastic Granulator?

A Standard Plastic Granulator is a highly efficient machine designed to reduce various types of plastic waste into small, uniform particles. These machines can handle plastic bottles, pipes, containers, woven bags, and other materials, making them ideal for the recycling industry.

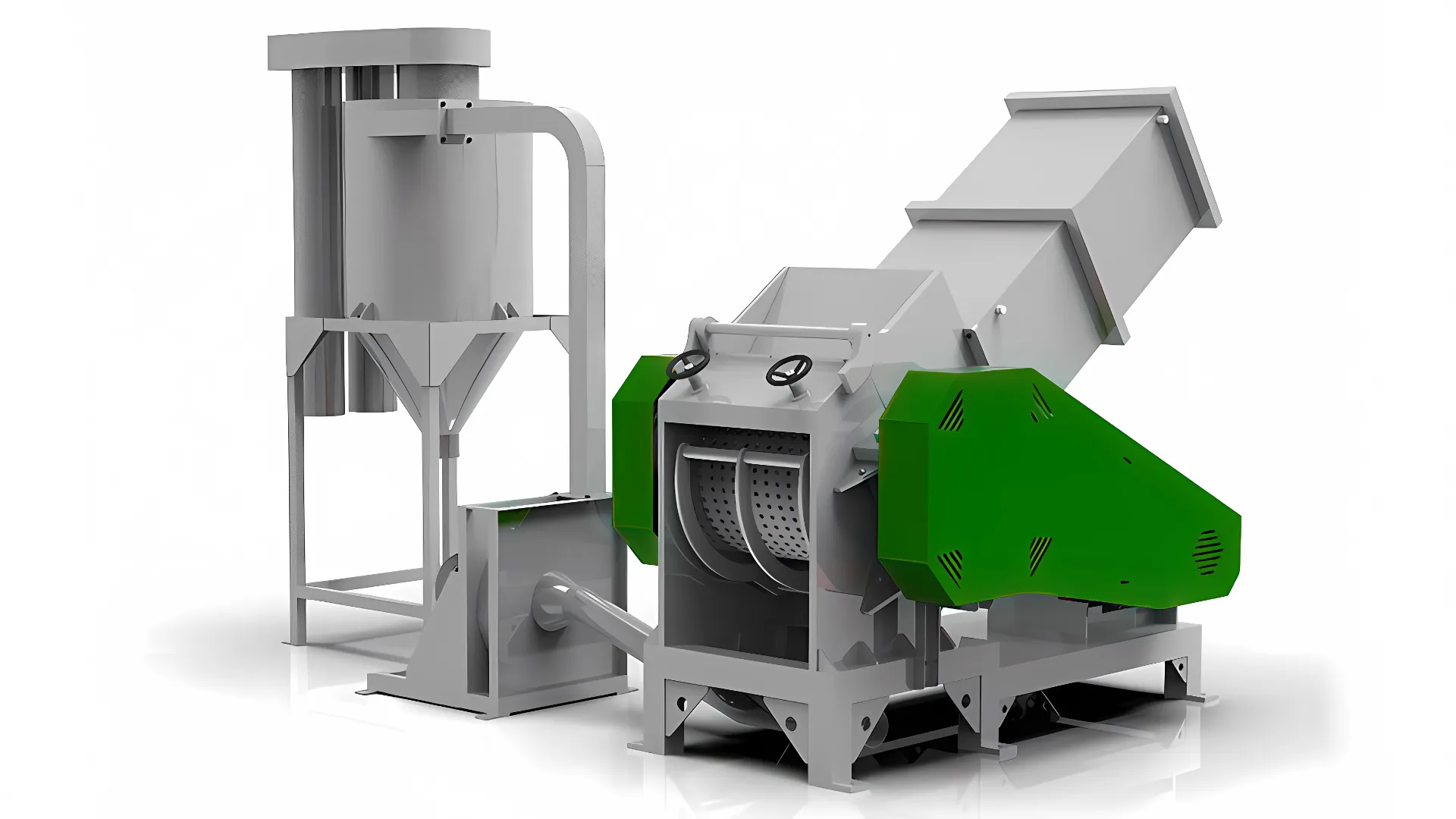

How Does a Plastic Granulator Work?

The granulation process involves the use of a rotating cutter wheel mechanism:

- Step 1: The rotating cutter wheel rapidly cuts and crushes the plastic waste.

- Step 2: Crushed pieces enter the sieve hole as the wheel rotates, further reducing the size of the plastic.

- Step 3: The sieve refines the granules into uniform particles, ready for reuse or additional processing.

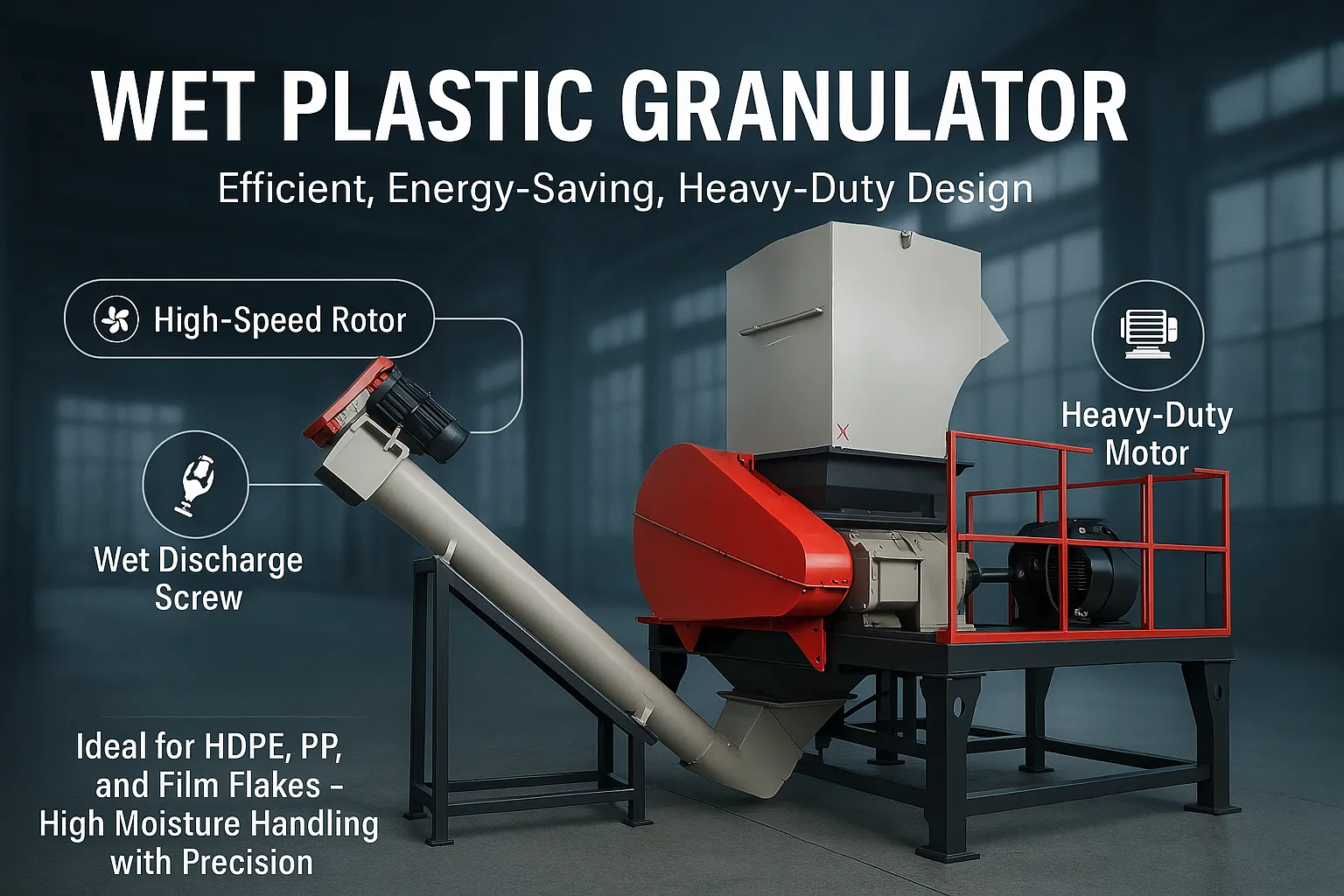

Key Features of Standard Plastic Granulators

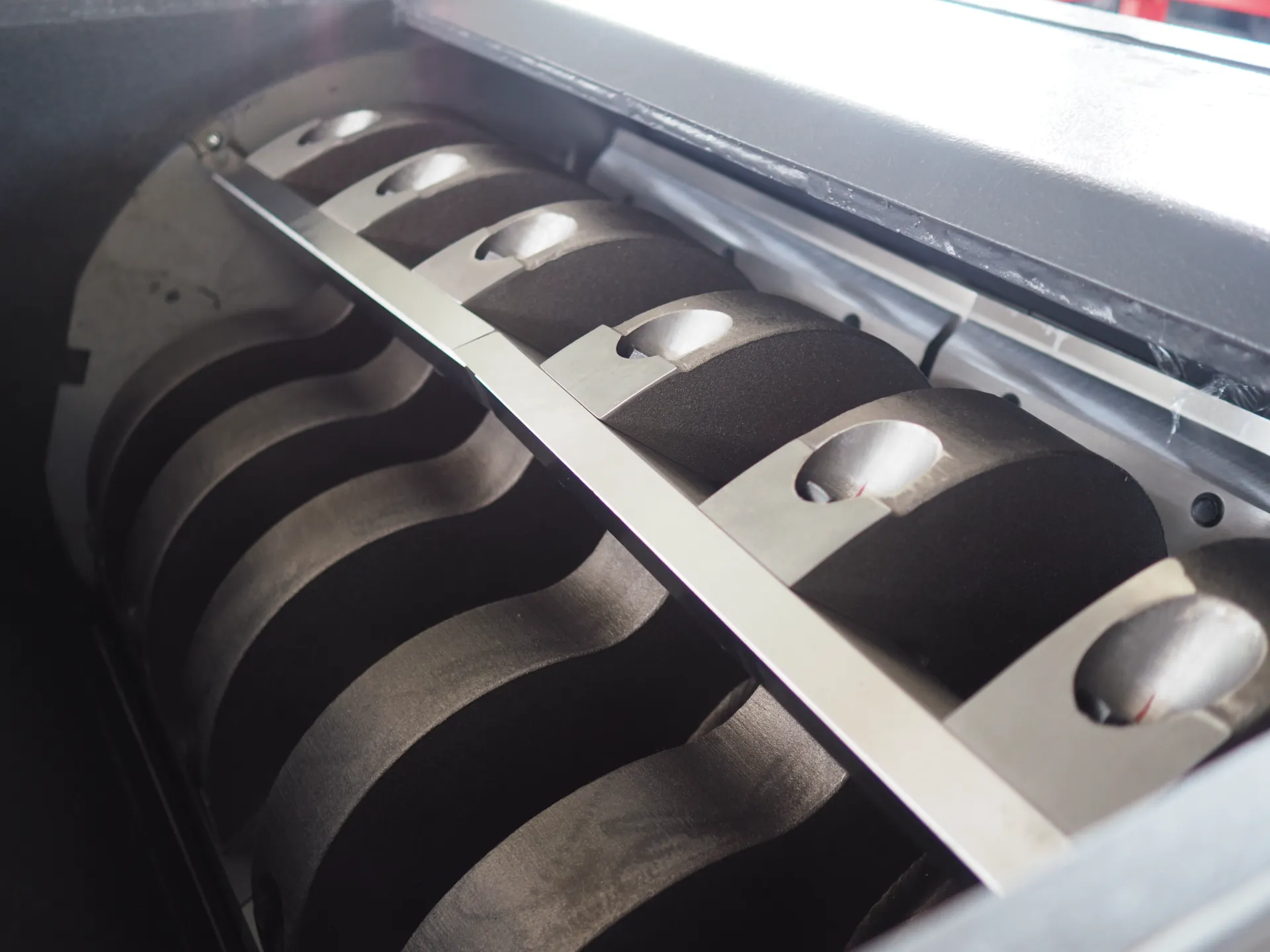

- Open Rotor Design: Mounted with heavy-duty knives for efficient cutting.

- Flexible Knife Arrangement: Options for double-scissor or v-shape cuts for different materials.

- High-Speed Operation: Ensures rapid and consistent granulation.

- Customizable Screen Filters: Ranging from 10mm to 100mm, based on specific needs.

- Durable Knife Construction: Equipped with 12 rotor knives and 3 stationary knives made from durable D2 steel.

- Easy Maintenance: Hydraulic-assisted access to the cutting chamber for easy knife adjustments.

Technical Parameters

| Model | Rotating Speed (rpm/min) | Rotary Diameter (mm) | Main Motor Power (kW) | Knife Material | Capacity (kg/h) |

|---|---|---|---|---|---|

| RTM-500 | 550 | Φ500 | 45kW | SKD11 | 500-800 |

| RTM-600 | 500 | Φ600 | 55kW | SKD11 | 800-1500 |

| RTM-700 | 428 | Φ700 | 90kW | SKD11 | 1500-2000 |

| RTM-800 | 370 | Φ800 | 110kW | SKD11 | 2000-2500 |

Benefits of Using Standard Plastic Granulators

- Environmental Protection: Helps minimize plastic waste pollution.

- Cost Reduction: Reduces waste disposal expenses and enhances operational efficiency.

- Resource Efficiency: Supports plastic recycling and reuse, contributing to a circular economy.

- Operational Simplicity: Easy to operate, with user-friendly controls and a reliable design.

- Versatility: Adaptable to different material characteristics and processing requirements.

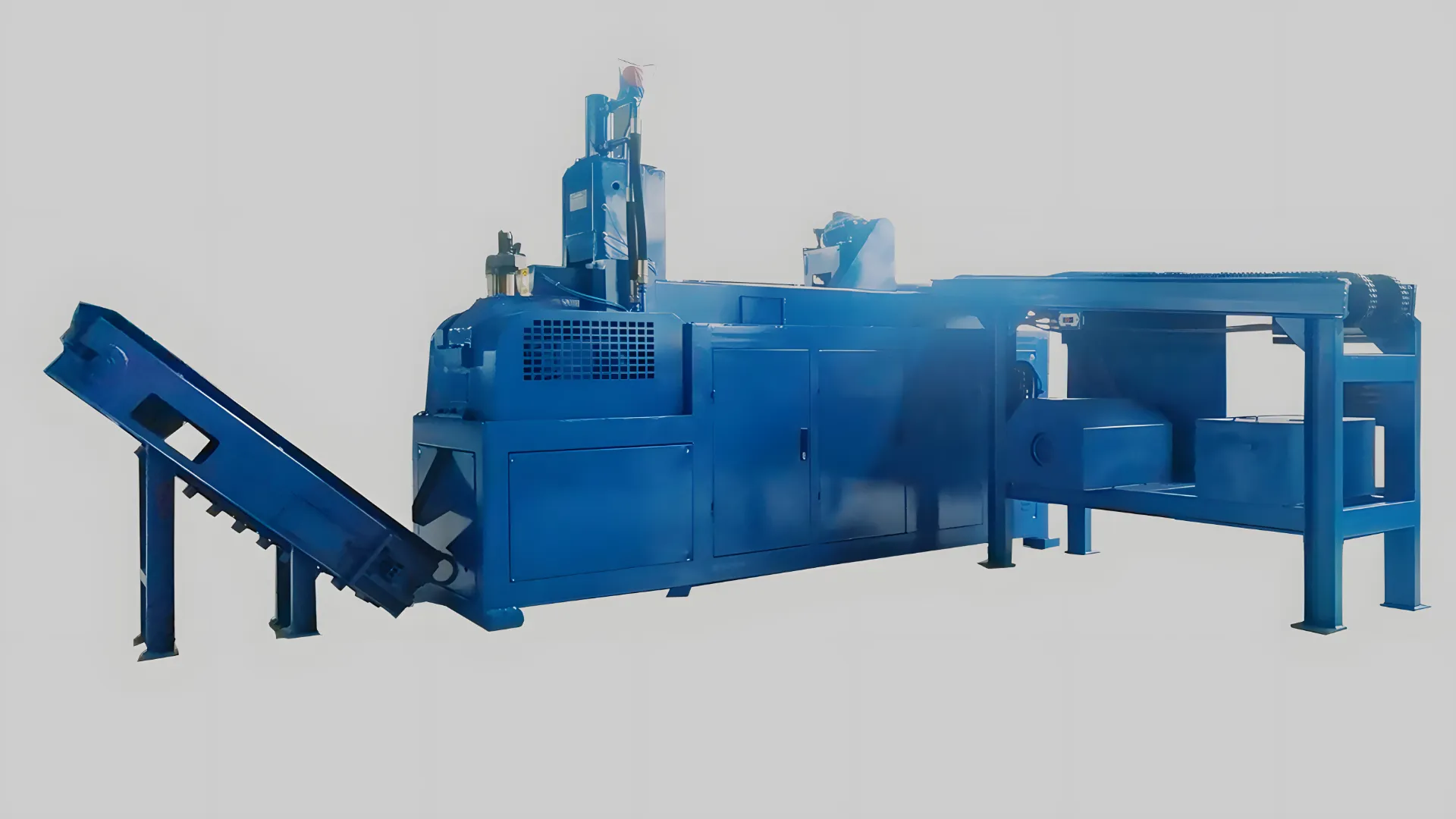

Applications in the Recycling Industry

Standard Plastic Granulators are crucial in a wide range of recycling applications:

- Post-Consumer Plastic Waste Recycling: Converts waste plastic into reusable raw materials.

- Industrial Plastic Scrap Recovery: Reduces plastic scrap from manufacturing processes for reuse.

- Plastic Product Manufacturing Waste Reduction: Recycles defective or excess plastic material in production lines.

- Pre-Processing for Advanced Recycling Technologies: Ideal for material preparation before advanced recycling processes like chemical recycling.