Recycling Products

More recycling equipment

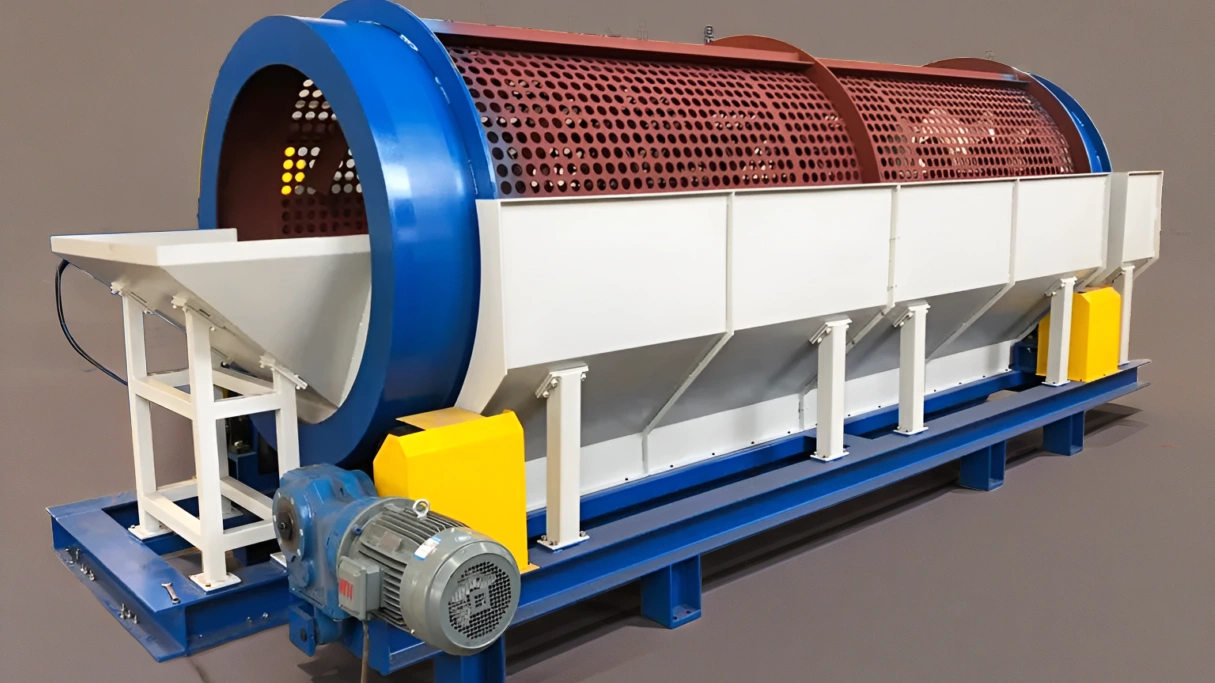

MSW Sorting System

Our Municipal Solid Waste (MSW) Sorting System efficiently separates mixed waste streams, recovering valuable recyclables and reducing landfill volume. Features a rotating trommel screen for size separation and automated sorting technology.

Read More

Baler Machine

High-capacity baler designed for recycling facilities and waste management centers. Compresses various materials including cardboard, plastic, and metal into dense, easily transportable bales. Improves storage efficiency and reduces transportation costs.

Read More

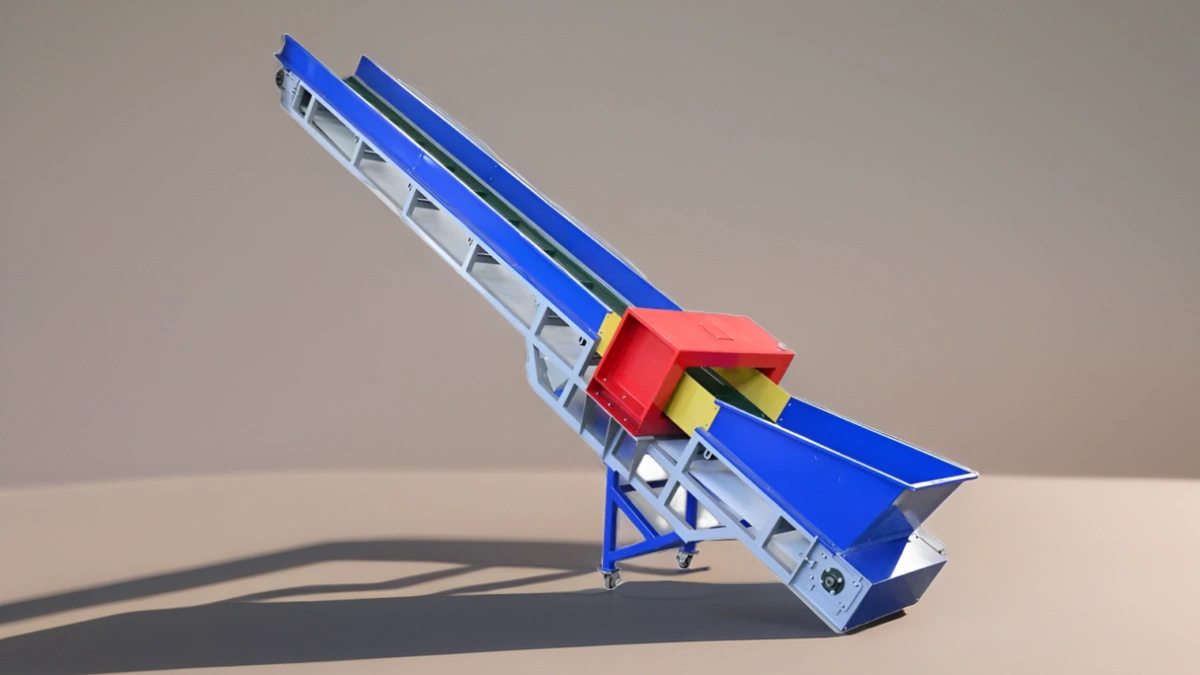

Assistive System

Advanced conveyor system with integrated sorting capabilities. Designed to enhance manual sorting operations, improving efficiency and worker safety. Features adjustable height and ergonomic design to reduce strain during the recycling process.

Read More

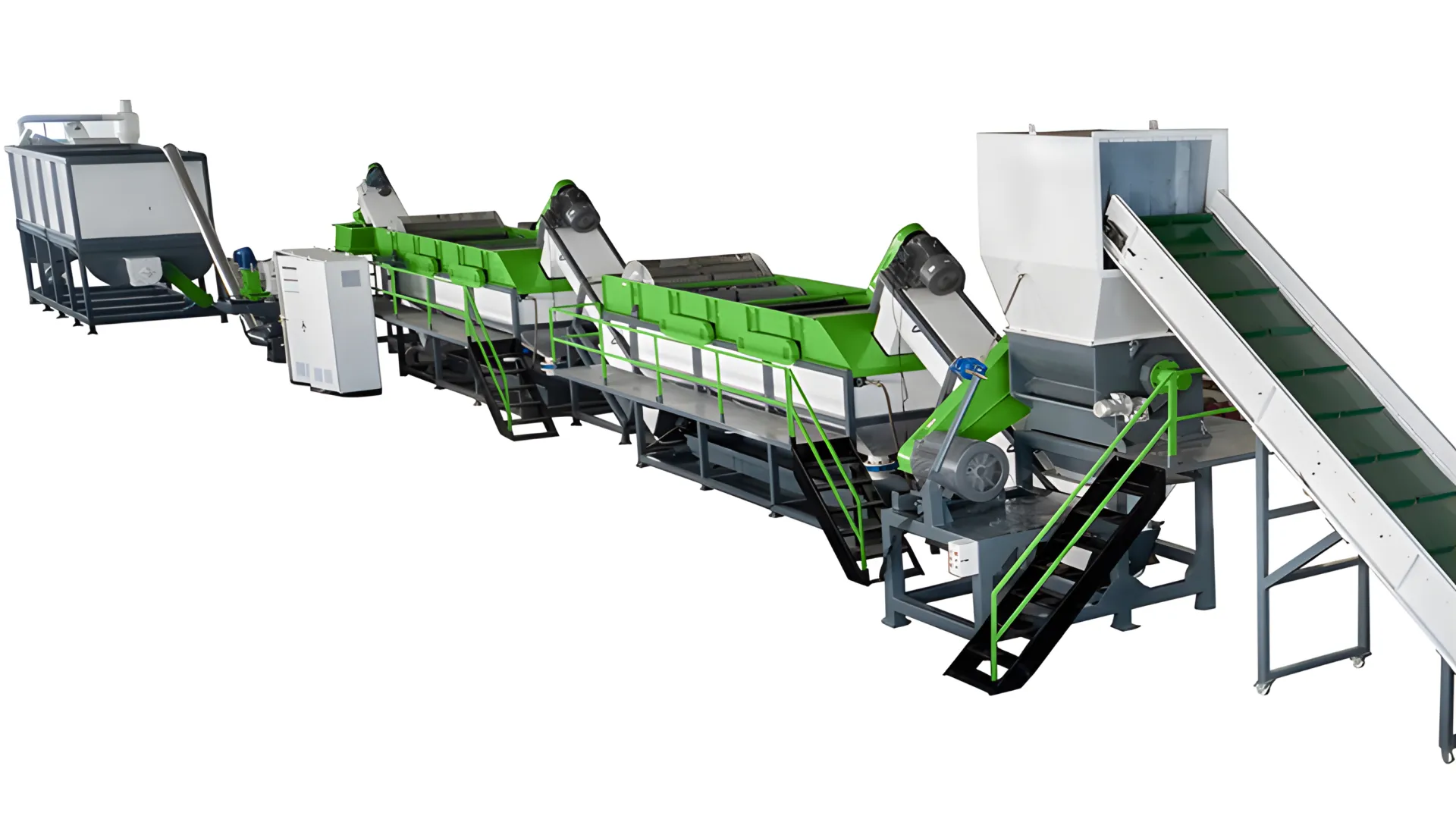

Washing Recycling Line

Comprehensive washing system for plastic recycling. Removes contaminants and labels from various plastic types, preparing materials for high-quality recycling. Includes pre-washing, intensive washing, and drying stages for optimal cleanliness.

Read More

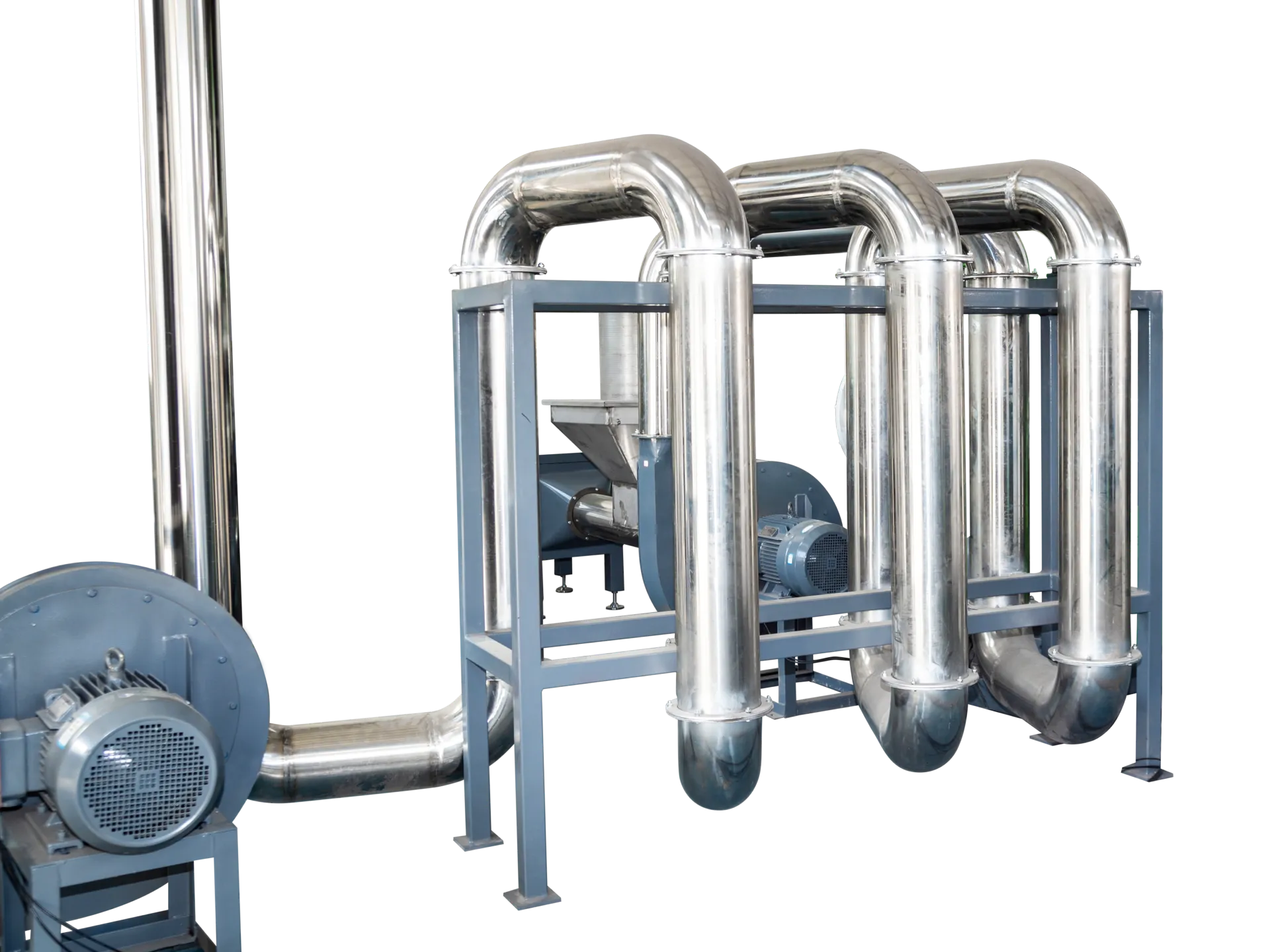

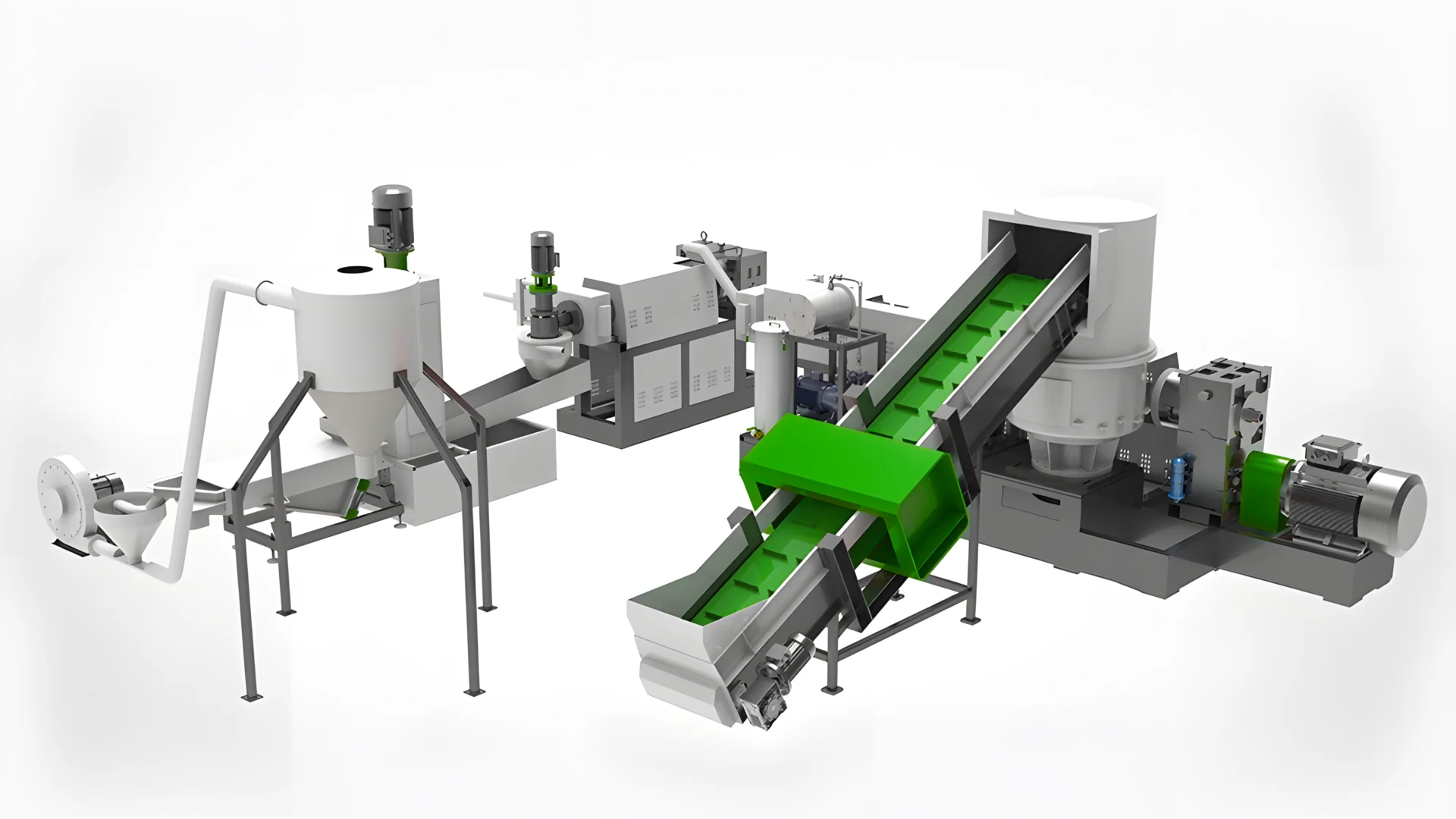

Pelletizing Machine

State-of-the-art pelletizing system converts cleaned and sorted plastic flakes into uniform pellets. Essential for producing high-quality recycled plastic raw materials. Features precise temperature control and customizable die plates for various plastic types.

Read More

Crusher

Heavy-duty crusher designed for size reduction of various materials including plastics, wood, and light metals. Enhances recycling efficiency by preparing materials for further processing. Equipped with replaceable blades and adjustable crushing chamber.

Read More

Placing An Order Easy

Just Follow The Steps

Whether you require a single plastic recycling machine, a turnkey recycling plant, or a bespoke recycling solution, we guarantee top-tier customer service and communication for efficient order processing and project execution.

Here’s our standard procedure for initiating orders and custom projects:

Plastic Recycling Machine Blogs

Insights and Updates on Recycling Technology

Stay informed with our latest blog posts covering a wide range of topics in the plastic recycling industry. From innovative machine designs to best practices in recycling processes, our blogs offer valuable insights for both industry professionals and environmental enthusiasts.

Latest From Media

Stay Informed with Our Device Videos

Explore our collection of informative videos showcasing our latest plastic recycling machines in action. From product demonstrations to maintenance tips, our media section keeps you updated on the cutting-edge technology in plastic recycling.