Key Features of Our Industrial Shredders

Our shredders are designed to handle a wide range of plastics, including ABS, Acetal, Acrylic, HDPE, HMWHDPE, LDPE, LLDPE, Nylon 6 and 66, PC, PET, Polyamide, Polyester, PP, PS, PU, PUR, PVC, TPE, TPO, UHW-PE, and composite materials, efficiently reducing them to the desired size.

Engineered for durability and high-performance waste processing, our industrial shredders are available in a variety of models to meet diverse shredding requirements. Whether you need secure waste disposal or efficient material reduction, our shredders deliver unmatched reliability and performance, making them the preferred choice in the industry.

Heavy-Duty Construction

Built to last, our industrial shredders feature heavy-duty construction that withstands demanding operational environments.

- ✓Durable materials

- ✓Robust design

- ✓High operational efficiency

Versatile Shredding Options

Our shredders offer multiple shredding options, making them suitable for various materials including plastics, metals, and paper.

- ✓Multiple blade configurations

- ✓Convenient size options

- ✓Customizable settings

Energy Efficiency

Designed with energy efficiency in mind, our industrial shredders help reduce operational costs while maximizing output.

- ✓Low power consumption

- ✓High throughput

- ✓Eco-friendly design

Safety Features

Safety is our priority; our shredders come equipped with advanced safety features to protect operators.

- ✓Automated shut-off

- ✓Emergency stop button

- ✓Protective covers

User-Friendly Interface

Our shredders are designed with user-friendly controls ensuring ease of operation for all users.

- ✓Intuitive controls

- ✓Clear display

- ✓Simple setup

Comprehensive Support

We provide extensive customer support, offering guidance from purchasing to maintenance, ensuring your shredder operates optimally.

- ✓24/7 support

- ✓Maintenance services

- ✓Parts availability

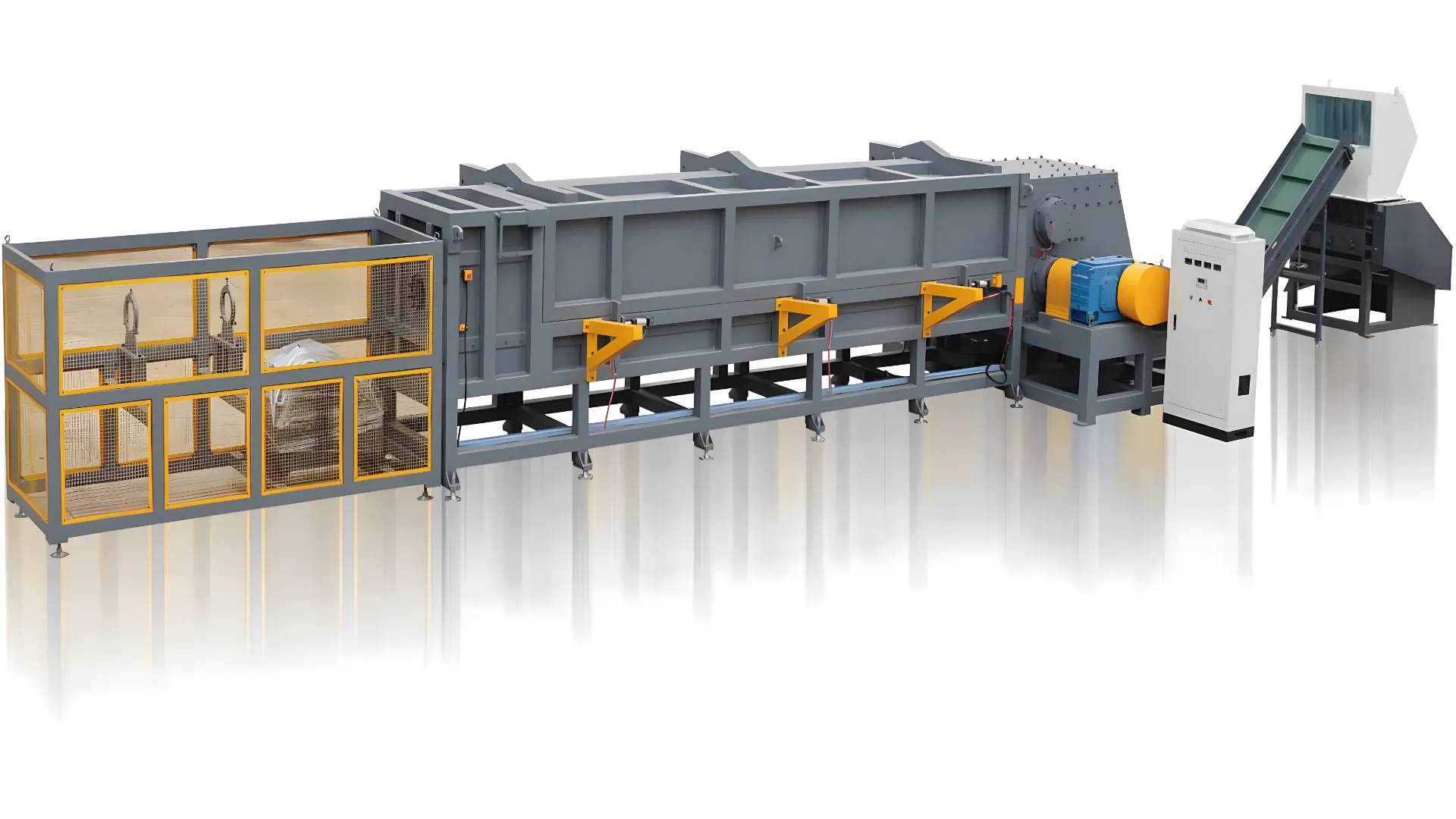

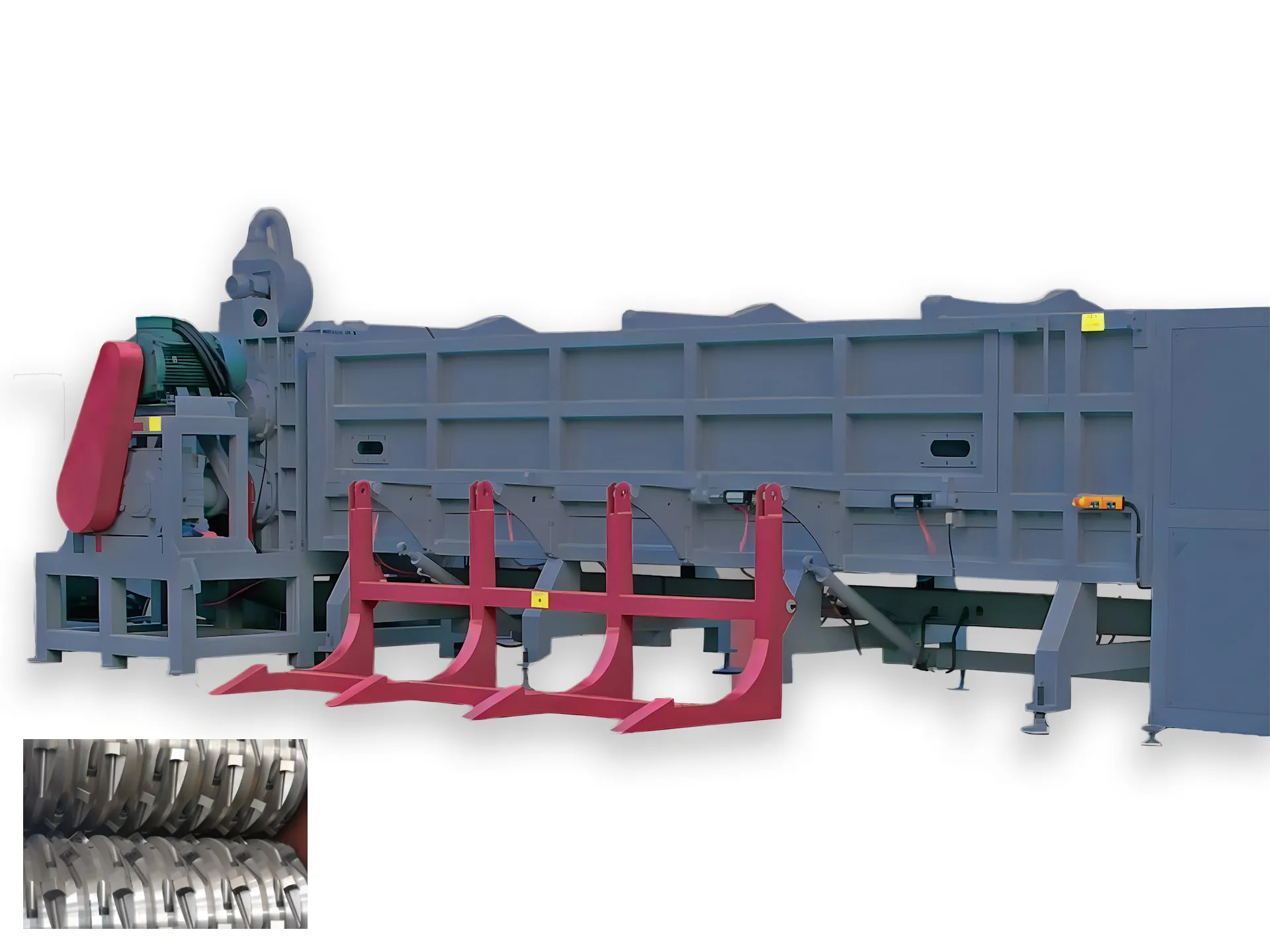

Understanding Single Shaft Metal Shredders

Core Technology and Design

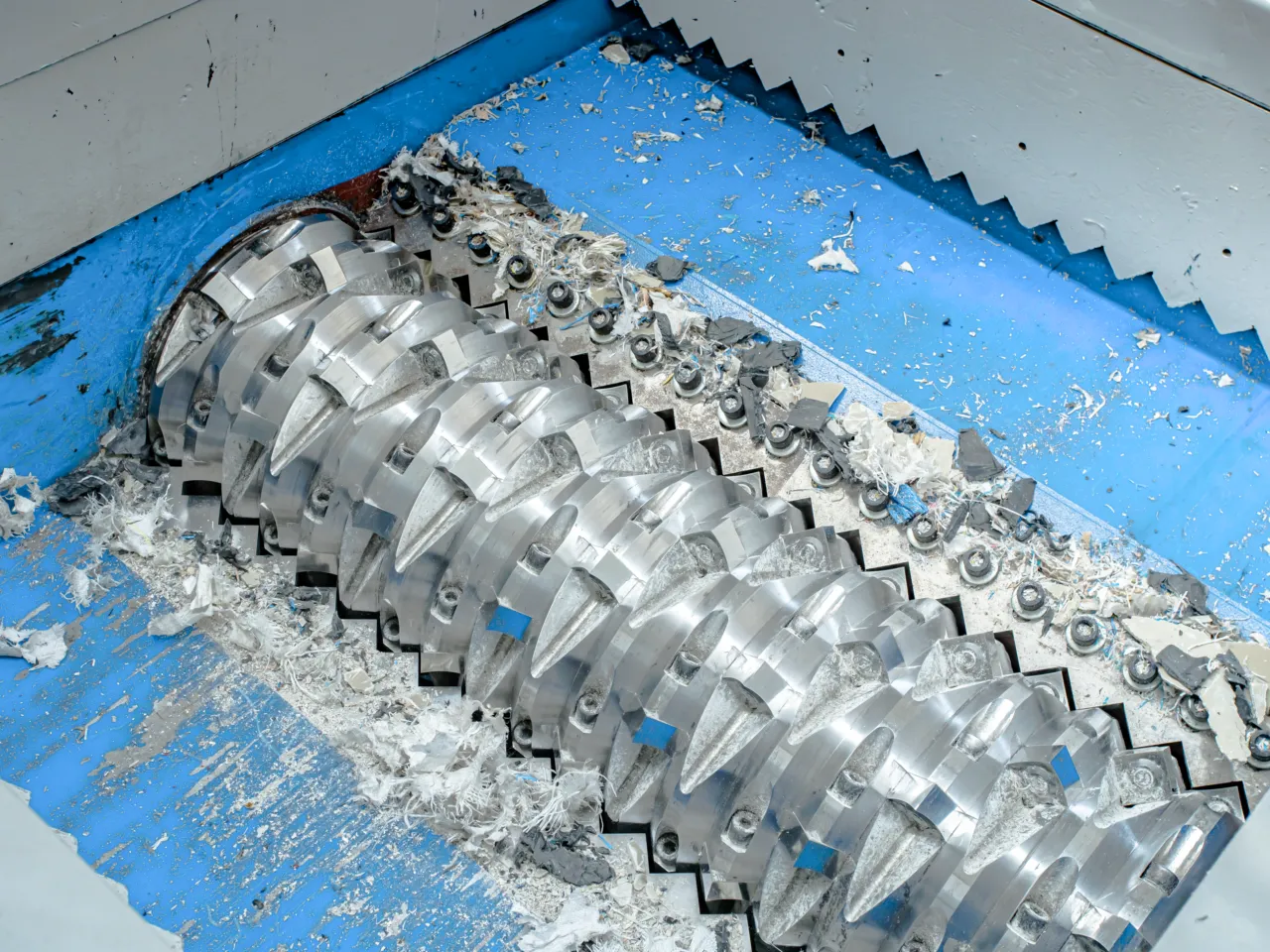

Single shaft metal shredders represent a specialized category of industrial shredding equipment designed specifically for processing metal chips and turnings. Unlike their multi-shaft counterparts, these machines feature a single rotor shaft equipped with hardened steel knives or blades that rotate against stationary counter knives.

Key Features:

- ✓ A powerful, low-speed, high-torque drive system

- ✓ Hydraulic ram feed mechanism for consistent material processing

- ✓ Precision-engineered cutting chamber with adjustable clearances

- ✓ Hardened tool steel blades with specialized geometry for metal chip processing

- ✓ Advanced control systems for operational monitoring and safety

Key Operational Principles

Single shaft shredders operate on a simple yet effective principle. The hydraulic pusher ram forces metal chips against the rotating knives, where they're cut against the stationary counter knives. This creates a continuous shearing action that reduces chips to uniform, manageable pieces. The size of the output material is controlled by a perforated screen at the bottom of the cutting chamber, ensuring consistent output dimensions.

Applications in Chip Processing

Types of Metal Chips Processed

- Long, stringy turnings from lathes and CNC machines

- Bushy, tangled chips from drilling operations

- Short, broken chips from milling processes

- Mixed metal chip waste streams

Integration in Manufacturing

Forward-thinking manufacturers are increasingly integrating single shaft shredders directly into their production lines. This integration creates a closed-loop system where chips are:

- Generated during machining operations

- Automatically conveyed to the shredder

- Processed into uniform, dense material

- Prepared for briquetting or direct recycling

Economic Benefits for Investors and Businesses

Enhanced Material Value and Recovery

Increase in metal scrap value

Reduction in transportation costs

Recovery rate of cutting fluids

Operational Cost Savings

Technical Considerations for Implementation

Sizing and Capacity Planning

Selecting the appropriate shredder size is critical for optimal performance. Key factors to consider include:

- Daily Chip Throughput: Estimate the daily volume of chips (in kg) requiring processing.

- Metal Variety: Identify the specific types of metals (aluminum, steel, titanium, etc.) to be shredded.

- Chip Physical Properties: Assess the characteristics of the chips (stringy, bushy, broken) as this affects shredder selection.

- Space and Infrastructure: Evaluate available floor space and existing facility infrastructure.

- Integration with Existing Systems: Determine how the new shredder will integrate with your current material handling and processing systems.

Material-Specific Configurations

Aluminum Chips

- Specialized knife geometries to prevent material adhesion

- Higher RPM operation for clean cuts

- Advanced cooling systems to prevent material melting

Steel Turnings

- Reinforced cutting elements with specialized metallurgy

- Lower RPM operation with higher torque

- Robust hydraulic systems to handle material density

Titanium and Specialty Alloys

- Premium blade materials with enhanced wear resistance

- Precision clearance adjustments to prevent jamming

- Advanced control systems to monitor processing parameters

Environmental and Sustainability Impact

Resource Conservation Benefits

Reclaims valuable metals for reuse in manufacturing

Recovers cutting fluids and coolants for reprocessing

Reduces the need for virgin metal production

Minimizes transportation-related carbon emissions

Decreases landfill utilization for industrial waste

Investment Considerations and ROI Analysis

Capital Expenditure Planning

When evaluating single shaft shredders as a capital investment, consider:

- Initial equipment cost ($15,000-$50,000 depending on capacity and features)

- Installation and facility modification expenses

- Operator training requirements

- Preventative maintenance program development

- Potential production disruption during implementation

Return on Investment Factors

A properly implemented single shaft shredder system typically delivers ROI through:

- Increased value of processed metal scrap (15-30% premium)

- Recovered cutting fluids and coolants (5-15% of operational fluid costs)

- Reduced transportation expenses (65-75% reduction in shipping volume)

- Lower labor costs for material handling (30-50% reduction)

- Decreased equipment wear on downstream processes

Many operations report complete ROI within 12-24 months for properly sized and implemented systems.

Future Trends in Single Shaft Shredding Technology

Emerging Innovations

The next generation of single shaft shredders is incorporating advanced features:

- IoT connectivity for real-time performance monitoring and predictive maintenance

- Enhanced automation with robotic feeding systems

- AI-driven operational optimization for different material types

- Energy recovery systems to reduce power consumption

- Advanced metallurgy for extended knife life and improved performance

Industry Adoption Trajectory

Market analysis indicates accelerating adoption of advanced chip processing technology across manufacturing sectors:

- Automotive manufacturing leading implementation trends

- Aerospace increasingly adopting dedicated systems for specialty alloys

- Contract manufacturers seeking competitive advantages through material recovery

- Small and medium enterprises accessing technology through service providers

Conclusion

Single shaft metal shredders represent a critical technology for modern manufacturing operations processing metal chips. Beyond the immediate operational benefits, these systems deliver significant economic and environmental advantages that align with both profit-focused business objectives and sustainability initiatives. For investors and business leaders in metal processing industries, understanding and implementing this technology has become essential for maintaining competitive advantage in an increasingly resource-conscious global marketplace.

By transforming what was once considered waste into valuable resources, single shaft metal shredders exemplify the intersection of smart business practice and environmental stewardship—a combination that defines forward-thinking manufacturing in today's economy.

| Model | Unit | ERMSD600 | ERMSD800 | ERMSD1000 | ERMSD1200 |

|---|---|---|---|---|---|

| Outer size | mm | 2150×1420×1800 | 3050×1620×2150 | 3350×1950×2800 | 3350×1950×2800 |

| Inlet size | mm | 915×600 | 1350×800 | 1450×1000 | 1450×1200 |

| Rotation diameter | mm | 300 | 355 | 355/400 | 415 |

| Rotation Speed | rpm | 72 | 72 | 72 | 72 |

| Screen Aperture | mm | 40-60 | 40-80 | 40-100 | 40-100 |

| Moving blade qty | pcs | 30 | 44 | 56 | 68 |

| Fixed blade qty | pcs | 4 | 4 | 4 | 4 |

| Motor power | kw | 22/30 | 37/45 | 55/75 | 75/90 |

| Hydraulic station | kw | 2.2 | 3 | 4 | 5.5 |

| Push range | mm | 600 | 800 | 1000 | 1200 |

| Capacity | kg/h | ≤600 | ≤800 | ≤1000 | ≤1500 |

| Weight | kg | 2300 | 3800 | 4900 | 6500 |

Ready to Revolutionize Your Metal Waste Management?

Contact our specialists to learn how single shaft metal shredders can enhance your operations.

In today’s fast-evolving industrial landscape, efficient and dependable machinery is crucial for processing tough materials. The Hard Material Single Shaft Shredder emerges as a cutting-edge solution, engineered for high-efficiency shredding of even the most challenging substances. Below, we explore its standout features, versatile applications, and why it’s a game-changer for modern industries.

Our Portable Pipe Shredder, meticulously tailored for a client in Canada, exemplifies our dedication to delivering personalized, efficient recycling solutions. This shredder is specifically engineered to manage the distinctive challenges of processing large extruded plastics and pipes, showcasing our proficiency in catering to unique customer needs.

A textile waste single shaft shredder is an efficient piece of mechanical equipment designed to shred and process waste generated during production. By cutting and shearing materials, it increases the density of waste, making it easier to handle, store, and recycle.

Boost your material processing with a high-performance, durable industrial shredder built for a wide range of applications.