Polystyrene, commonly found in products like foam cups, take-out containers, packaging materials, and disposable cutlery, is one of the most widely used yet environmentally problematic plastics in the world. Though convenient for consumers, the impact of polystyrene on our environment has been significant, especially since it’s non-biodegradable and accumulates in landfills and oceans. Recycling polystyrene, however, offers an effective solution to mitigate these environmental concerns.

Enter the polystyrene recycling machine—a revolutionary device that is transforming how we handle this persistent plastic waste. By turning polystyrene waste into reusable materials, these machines not only provide a method of waste reduction but also help reduce the demand for new plastic production, thus contributing to a more sustainable future.

In this article, we will explore everything you need to know about polystyrene recycling machines, including their workings, benefits, types, and why they are crucial in the fight against plastic pollution.

What is a Polystyrene Recycling Machine?

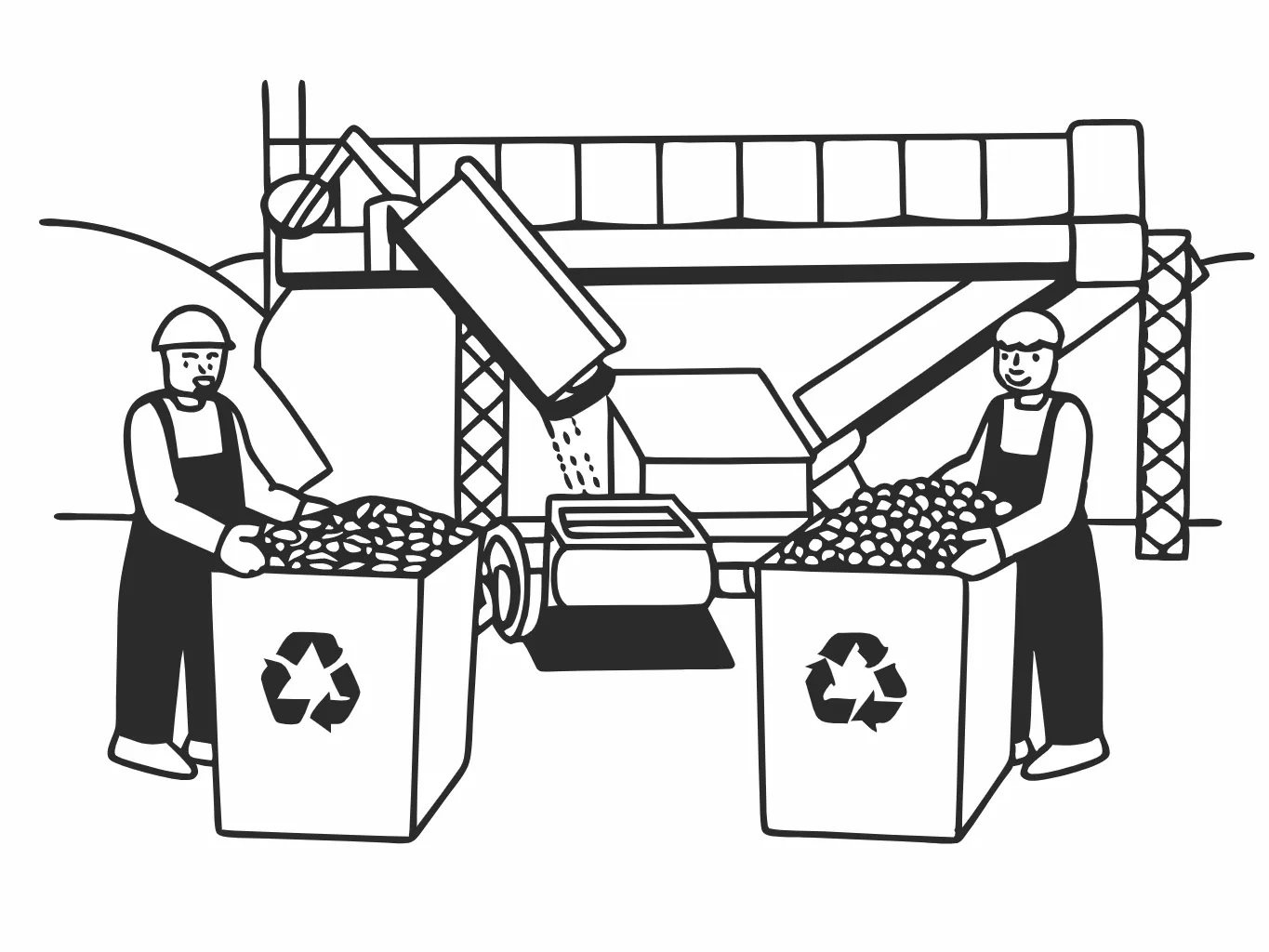

A polystyrene recycling machine is a specialized piece of equipment designed to process and recycle polystyrene foam and other polystyrene-based products. These machines can convert the foam into solid pellets or blocks that are easier to handle, transport, and reuse. They are engineered to melt and compact the polystyrene waste, reducing its volume significantly, making the recycling process more efficient.

Polystyrene recycling machines come in various sizes and configurations, depending on the scale of operation—ranging from small, industrial-sized units for individual businesses to larger, more advanced systems for municipal recycling plants.

How Does a Polystyrene Recycling Machine Work?

Polystyrene foam is typically bulky and lightweight, which makes it difficult to manage through traditional recycling methods. The core process behind the polystyrene recycling machine is to compress the foam and melt it down into a more manageable form. Here’s how it generally works:

- Collection and Preprocessing: The first step in recycling involves collecting polystyrene waste materials, which can come from packaging, food containers, or other disposable foam products. The waste is then sorted, cleaned, and shredded into smaller pieces to prepare it for processing.

- Melting and Compression: The shredded polystyrene is fed into the recycling machine, where it undergoes melting and compression. The heat from the machine melts the foam, causing it to shrink and lose its volume by up to 90%. This step significantly reduces the physical space the material occupies, making it easier to handle.

- Cooling and Solidifying: Once melted, the polystyrene is cooled and solidified into a compact form, such as blocks or pellets. These can be used to create new polystyrene products or be further processed into raw materials for manufacturing.

- Reuse: The end result is a more compact and durable form of polystyrene, which can then be sold or reused in various applications, such as construction, packaging, or as raw material in the production of new foam products.

Types of Polystyrene Recycling Machines

There are several types of polystyrene recycling machines, each designed for specific needs and recycling capacities. Let’s take a look at some of the common types:

1. Manual Polystyrene Compactors These are typically smaller, simpler machines that require manual labor to operate. They are ideal for businesses or individuals with smaller amounts of polystyrene waste. Manual compactors work by compressing the foam into blocks, which can then be transported or reused.

2. Automatic Polystyrene Recycling Machines Larger, more advanced machines are fully automated and can handle much larger volumes of foam waste. These machines often have conveyors, shredders, and automatic heating systems, allowing them to process materials with minimal human intervention. They are perfect for industrial settings, where efficiency and high throughput are crucial.

3. Extrusion Machines Extrusion machines use the heat and pressure generated by rotating screws to melt and compress polystyrene waste into small pellets. These pellets are then cooled and ready for reuse. Extrusion is especially useful for creating uniform, high-quality pellets that can be used in manufacturing new products.

4. Foam Crushers Foam crushers are specialized machines that break down polystyrene foam into smaller pieces. These machines are commonly used as the first step in the recycling process before the material is further processed in a compactor or extruder.

Benefits of Polystyrene Recycling Machines

The introduction of polystyrene recycling machines has been a game-changer in the fight against plastic pollution. Here are the major benefits these machines offer:

1. Reduces Landfill Waste

Polystyrene foam is not biodegradable and can sit in landfills for hundreds of years. By recycling it, polystyrene recycling machines help reduce the amount of foam that ends up in waste disposal sites, conserving valuable land and reducing pollution.

2. Saves Energy and Resources

Recycling polystyrene reduces the need for new plastic production, which requires significant amounts of fossil fuels and energy. By reusing recycled foam material, businesses can save on resources, decrease carbon footprints, and support sustainable manufacturing practices.

3. Contributes to Cleaner Oceans

Polystyrene foam is a major pollutant in our oceans, where it can be ingested by marine animals, causing harm or death. By recycling polystyrene, these machines help to prevent foam from ending up in water bodies, ultimately contributing to cleaner oceans and healthier marine life.

4. Economic Benefits

Polystyrene recycling machines not only help the environment but also present a financial opportunity. By investing in these machines, businesses can reduce disposal costs and even generate revenue by selling the recycled material or reusing it in their operations. This can lead to a more profitable, eco-friendly business model.

5. Reduces Carbon Footprint

The process of recycling polystyrene requires less energy than producing new polystyrene products from raw materials. This reduction in energy consumption lowers greenhouse gas emissions, contributing to a smaller carbon footprint for the manufacturing industry.

6. Provides Recycled Materials for New Products

The recycled material generated by these machines can be used to create a variety of products, such as insulation materials, construction products, and packaging. By reusing polystyrene, businesses can tap into a new supply of raw materials that are both affordable and environmentally responsible.

Challenges of Polystyrene Recycling

While polystyrene recycling machines offer a variety of benefits, there are some challenges associated with their use:

1. Contamination

Polystyrene waste is often contaminated with food or other materials, making it more difficult to recycle. Proper sorting and cleaning of materials before recycling is crucial to ensure the effectiveness of the recycling process.

2. Initial Investment

Polystyrene recycling machines can be expensive to purchase and install. Smaller businesses or municipalities with limited budgets may find it difficult to invest in these machines. However, the long-term benefits can outweigh the initial cost.

3. Limited Demand for Recycled Products

Despite the increasing awareness of environmental issues, there is still limited demand for recycled polystyrene products compared to virgin material. This can impact the viability of recycling efforts in certain regions.

FAQs About Polystyrene Recycling Machines

What are the key benefits of using a polystyrene recycling machine?

Polystyrene recycling machines help reduce waste, save energy, contribute to cleaner oceans, and provide economic benefits by recycling foam into reusable materials.

How does a polystyrene recycling machine work?

The machine collects polystyrene foam, shreds it, melts it, compresses it into compact blocks or pellets, and then cools it for reuse in manufacturing new products.

Can I recycle any type of polystyrene foam?

Most types of polystyrene foam, including food containers and packaging materials, can be recycled using a polystyrene recycling machine. However, it is important to remove contaminants like food residues before recycling.

How much space can a polystyrene recycling machine save?

A polystyrene recycling machine can reduce the volume of foam by up to 90%, significantly decreasing the space required for storage and transport.

What is the cost of a polystyrene recycling machine?

The cost of these machines varies depending on the size, type, and capacity. Smaller manual machines can cost a few thousand dollars, while industrial-scale automated machines can cost tens of thousands of dollars.

What products can be made from recycled polystyrene?

Recycled polystyrene can be used to produce a variety of products, including insulation, packaging materials, and construction materials like concrete blocks or bricks.

Conclusion

Polystyrene recycling machines are a crucial innovation in the ongoing fight against plastic pollution. These machines allow businesses and municipalities to reduce their environmental impact while generating valuable, reusable materials. By recycling polystyrene foam, we can reduce landfill waste, save resources, and contribute to a cleaner and greener planet. Despite some challenges, the benefits far outweigh the costs, making these machines a valuable investment for sustainable waste management solutions.

With growing awareness about the environmental impact of polystyrene, it’s essential that more industries adopt these recycling machines to tackle plastic pollution head-on. By taking proactive steps toward recycling, we can make a significant difference in preserving our planet for future generations.