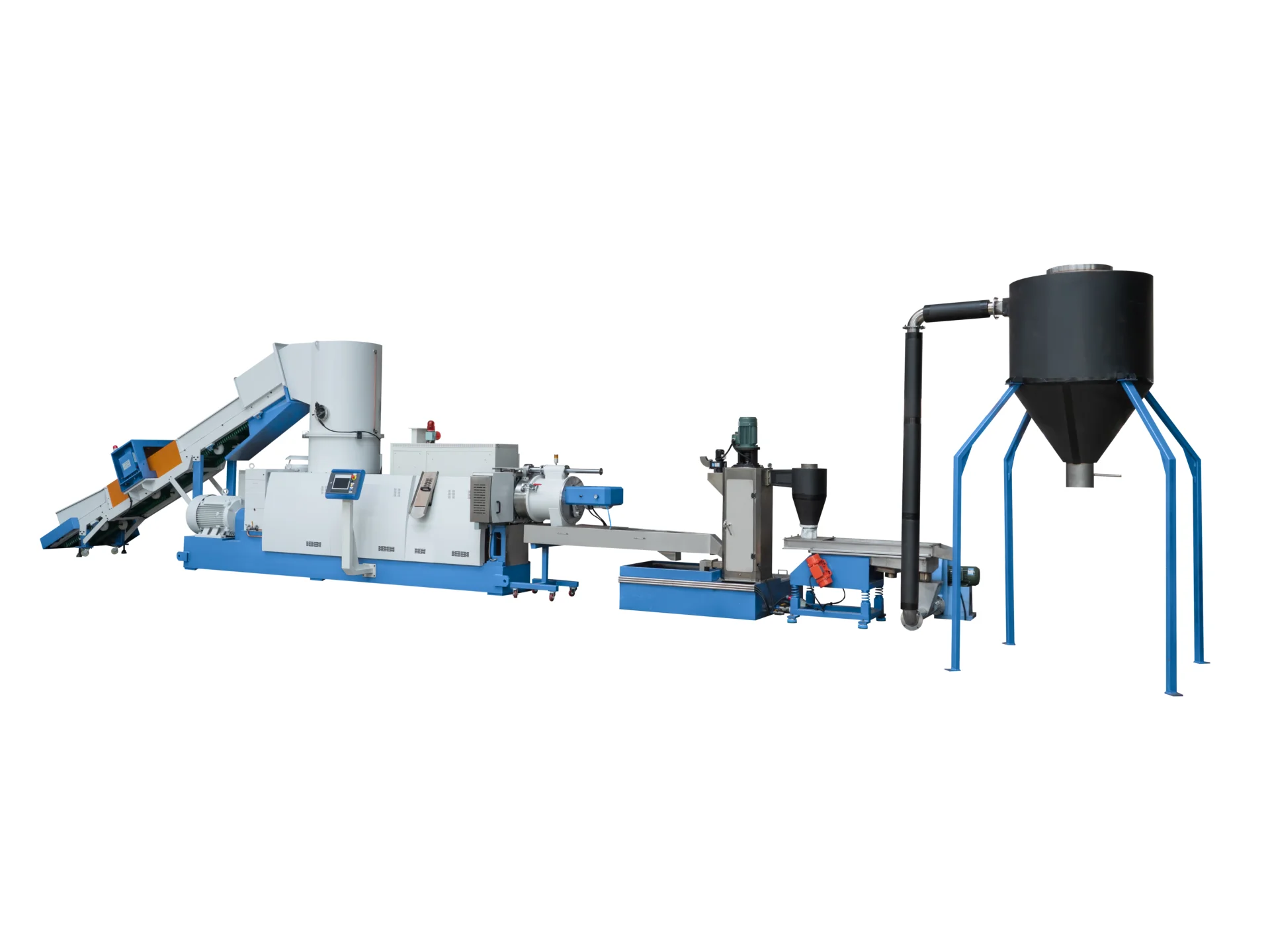

In the realm of plastic recycling, the PP/PE Film Pelletizing Machine represents a significant advancement. Engineered to process a diverse range of plastics—including HDPE, LDPE, LLDPE, PP, PS, PET, and PC—this machine epitomizes innovation in recycling technology.

Key Features and Advantages

- Versatile Processing: Capable of handling various plastic materials, the machine offers flexibility to meet different recycling needs.

- Robust Construction: Equipped with a durable stainless steel storage container, it ensures longevity and consistent performance.

- Efficient Operation: Incorporates pneumatic conversion, an effective wind-blowing system, water cooling, and a de-watering mechanism to optimize the pelletizing process.

- High-Quality Output: Produces uniform, high-quality pellets suitable for manufacturing new plastic products, thereby closing the recycling loop.

- Adjustable Capacity: With throughput ranging from 200kg/h to 1000kg/h, it caters to both small-scale and large-scale production requirements.

The Pelletizing Process

- Material Preparation: Plastic waste is collected and prepared for processing.

- Shredding/Crushing: The machine reduces the plastic waste into smaller, manageable pieces.

- Washing and Drying: The shredded plastic is cleansed to remove contaminants and then dried to eliminate moisture.

- Extrusion: The clean, dry plastic is melted and extruded through a die to form strands.

- Pelletizing: The extruded strands are cooled and cut into small pellets.

- Cooling and Drying: The pellets undergo further cooling and drying to ensure stability and moisture removal.

- Screening: The final pellets are screened to separate any dust or undersized particles.

- Packaging: The screened pellets are packaged for storage or transportation.

Environmental and Economic Impact

The PP/PE Film Pelletizing Machine addresses the critical issue of plastic waste by converting it into reusable pellets. This process not only diminishes environmental pollution but also conserves resources by reducing the demand for virgin plastic materials.

Economically, the machine offers substantial benefits. Businesses can reutilize the recycled pellets in their production lines, leading to significant cost savings on raw materials and enhanced operational efficiency.

Conclusion

The PP/PE Film Pelletizing Machine stands out as an innovative solution in plastic waste management. Its ability to process a variety of plastic materials into reusable pellets makes it an essential asset for businesses aiming to adopt sustainable practices and contribute to environmental conservation.

For detailed specifications and to explore how this machine can align with your recycling objectives, please reach out using the contact form below.

Main Technical Parameters

| Model | EMP2-85 | EMP2-100 | EMP2-120 | EMP2-150 | EMP2-160 | EMP2-180 |

|---|---|---|---|---|---|---|

| Capacity (KG/H) | 100-200 | 200-300 | 300-400 | 500-600 | 700-800 | 800-1000 |

| L/D | 1:33 | 1:33 | 1:33 | 1:36 | 1:36 | 1:36 |

| Install Power (KW) | 110 | 135 | 160 | 310 | 370 | 520 |

| Compactor Power (KW) | 37 | 45 | 55 | 110 | 132 | 180 |

| Main Extruder Power (KW) | 55 | 75 | 90-110 | 185 | 220 | 280-315 |

| Screen Exchanger | 160mm | 200mm | 250mm | 350mm | 400mm | 500+mm |

| Staff Requirement | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Overall Size (L*W*H) | 9*5*4 | 10*5*4 | 12*5*4 | 13*6*4 | 13*6*4 | 13*6*4 |

*Note: Specifications are subject to change based on specific requirements and configurations.

We are confident that the PP/PE Film Pelletizing Machine can assist you in achieving your production goals and delivering high-quality pellets that meet your clients’ expectations.

INQUIRIES

Warranty

All recycling machines come with a 1-year limited warranty.

To get the latest prices and lead times, send us a message using the form below.

[…] PP/PE Film Pelletizing Machine […]