Recycling News

Categories Recycling News

Posted on

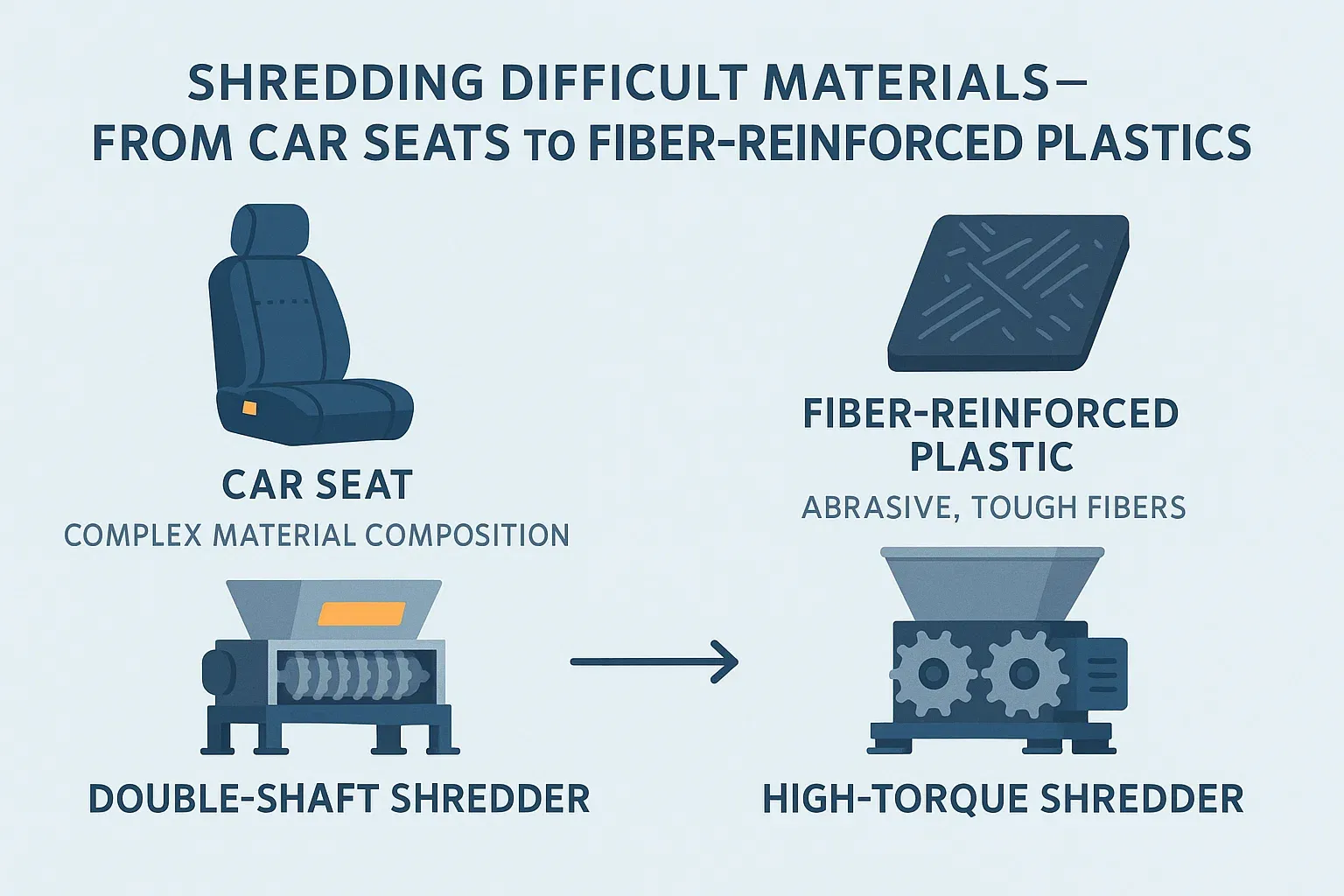

Shredding difficult materials such as car seats and fiber-reinforced plastics requires specialized equipment. Learn about the challenges these materials present and the most efficient shredding solutions, including double-shaft and high-torque shredders.

Categories Recycling News

Posted on

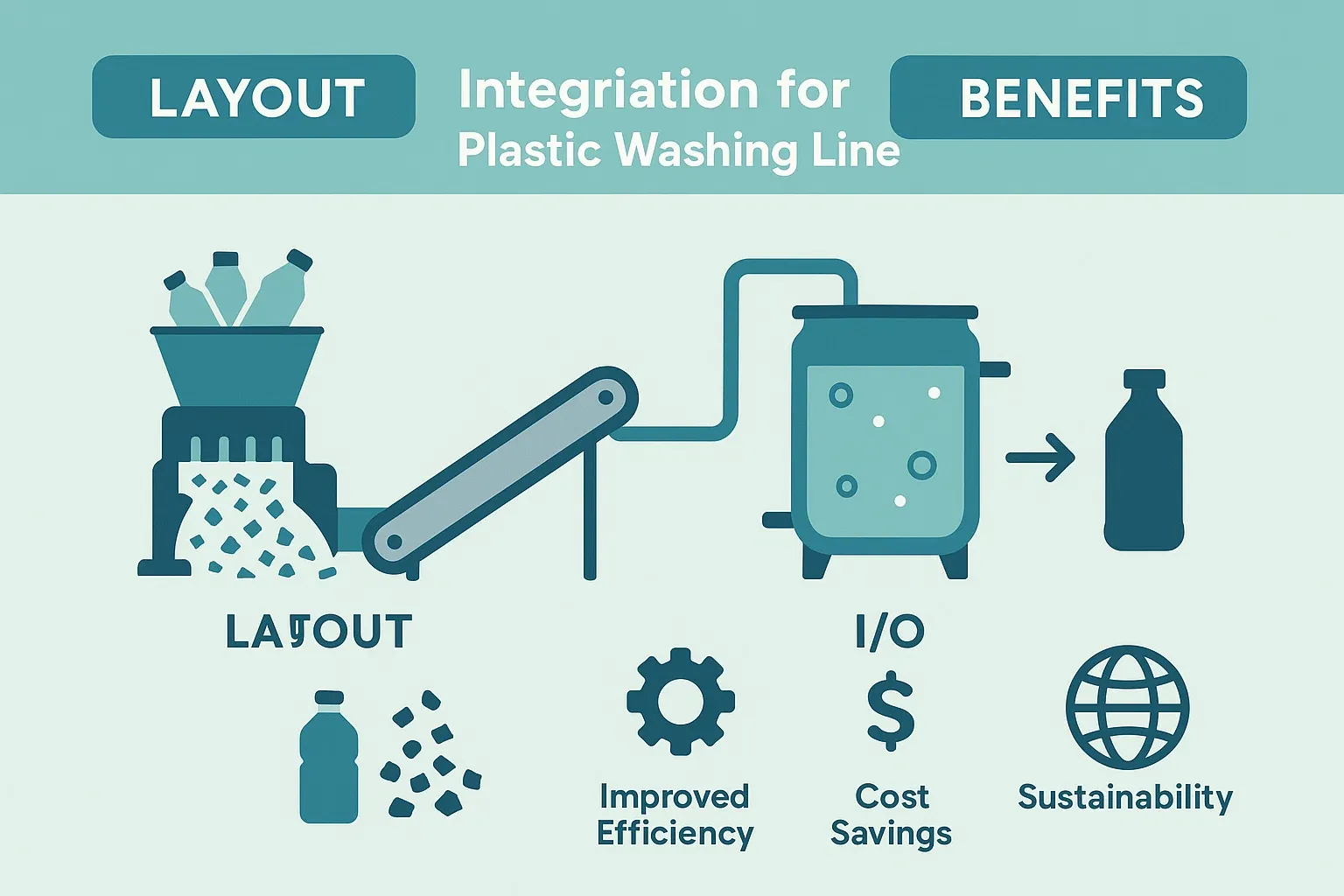

Boost your plastic washing line's productivity by integrating a plastic shredder. This guide covers crucial layout planning, I/O system integration, and performance checks to ensure seamless material flow, reduce costs, and produce higher quality recycled plastic.

Categories Recycling News

Posted on

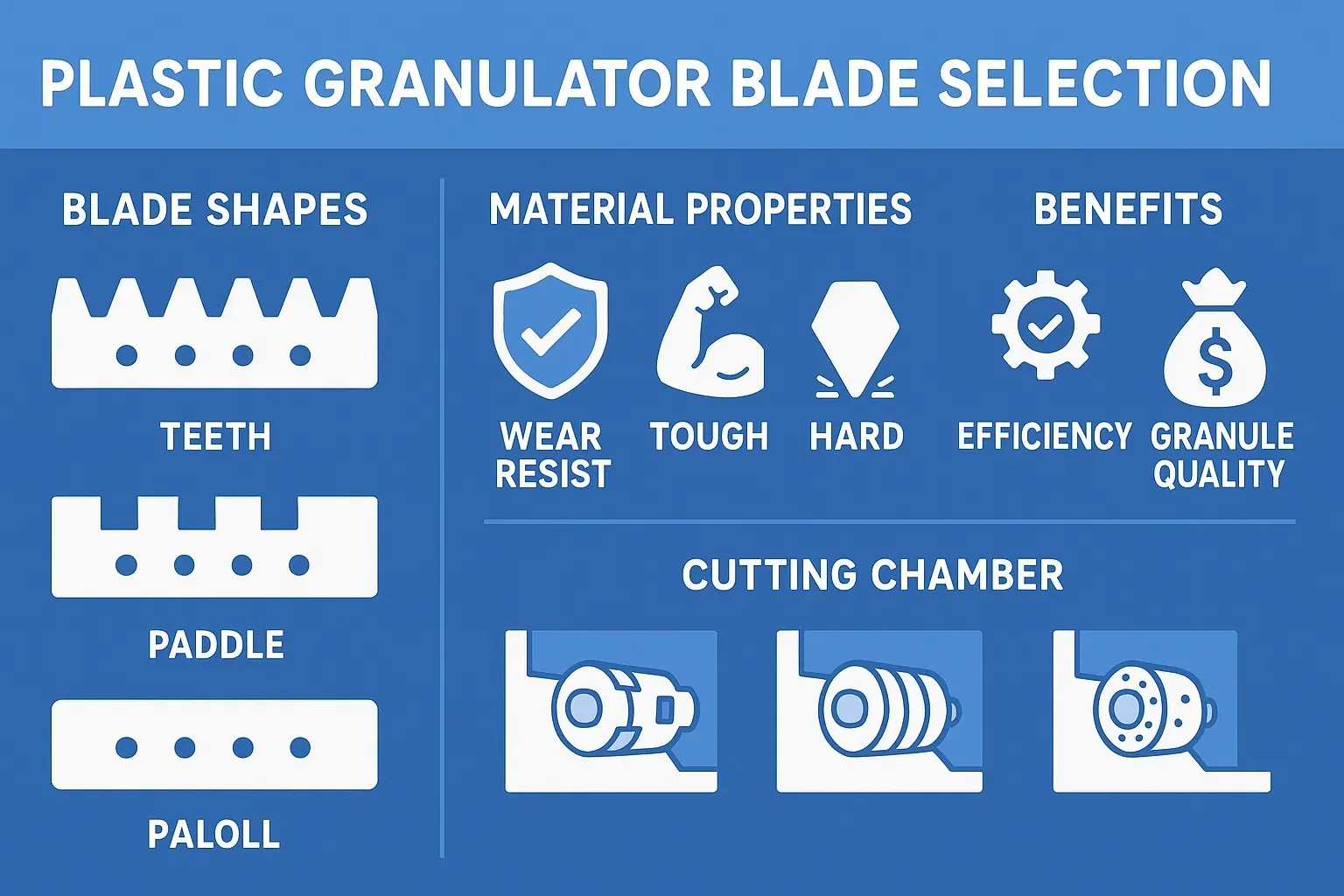

Selecting the right plastic granulator blades significantly impacts efficiency and operational costs. This guide covers key selection factors including blade material, blade design (teeth, staggered, paddle), and cutting chamber configuration to help you optimize throughput, improve granule quality, and minimize maintenance expenses in your plastic recycling or processing operations.

Categories Recycling News

Posted on

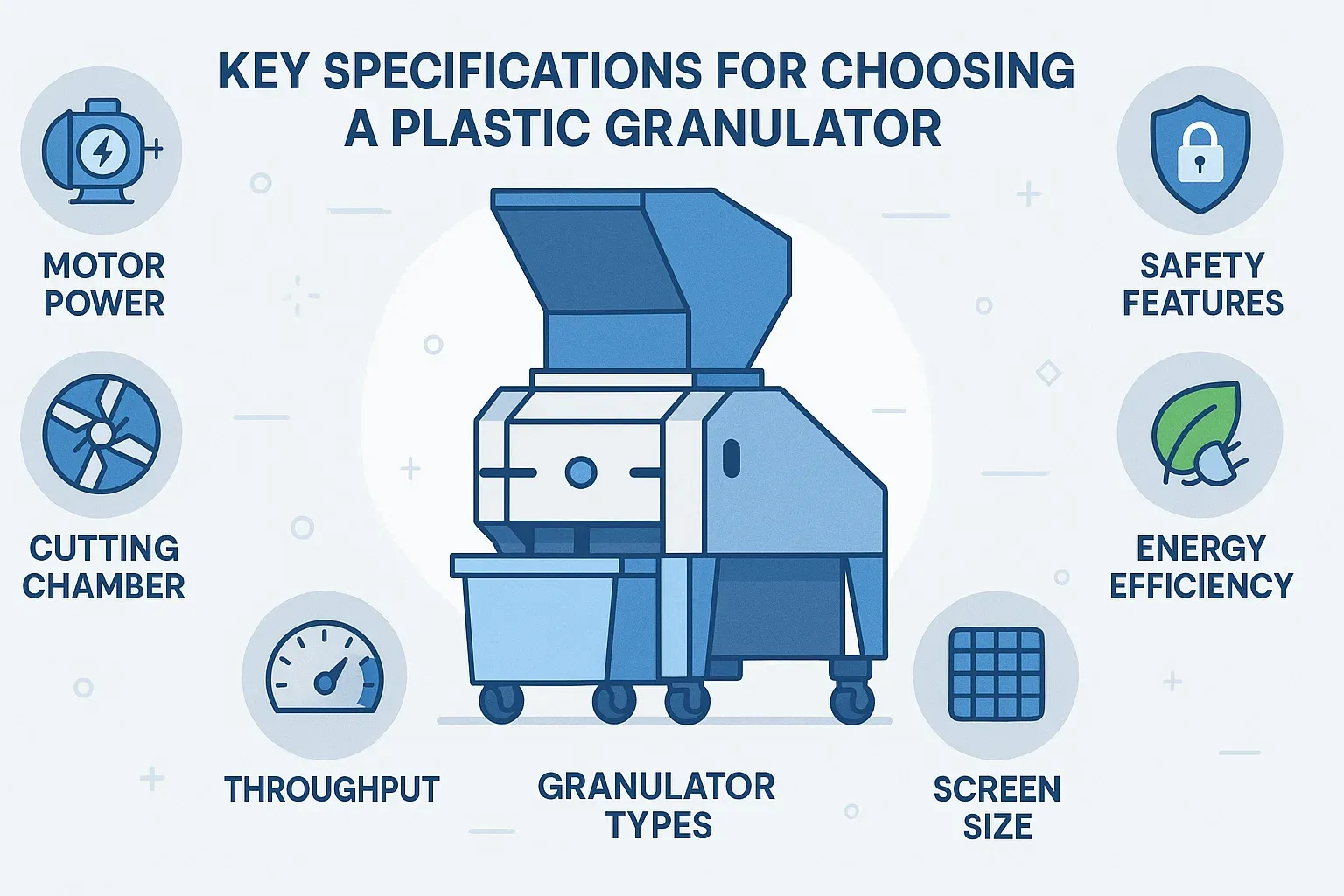

When selecting a plastic granulator, it's crucial to evaluate key technical specifications to ensure the equipment meets your operational needs. This guide covers the top 10 factors industrial buyers should consider.

Categories Recycling News

Posted on

Well-maintained plastic granulators run cooler, cut cleaner and save thousands in unplanned stops. This guide breaks down daily checks, monthly tasks and smart sensor upgrades that keep your regrind line humming—whether you’re an equipment buyer, plant engineer or hands-on technician.

Categories Recycling News

Posted on

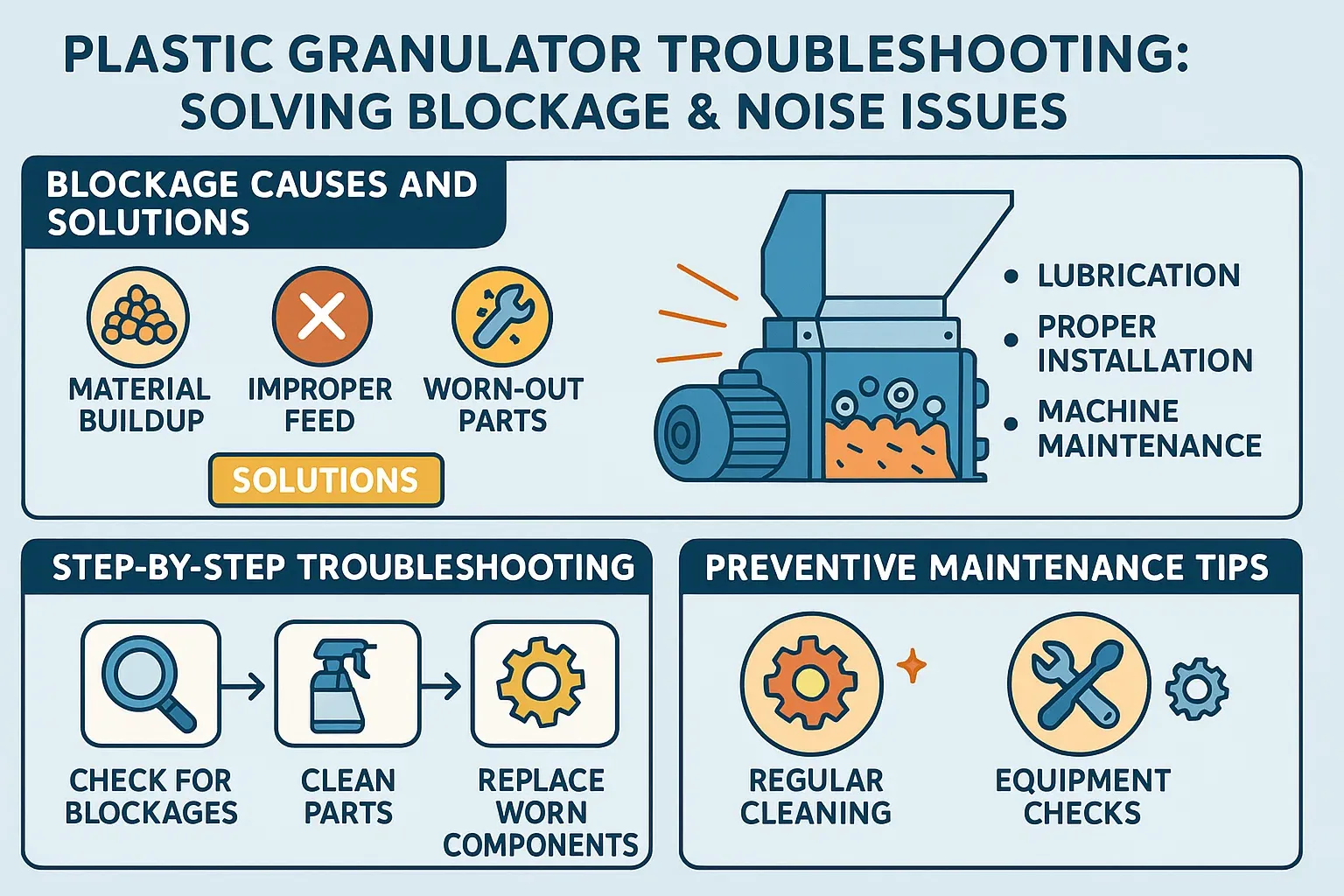

This article focuses on troubleshooting common issues encountered during the operation of plastic granulators, specifically addressing problems related to material blockages and excessive noise. It covers potential causes for these issues and provides effective solutions to help users quickly diagnose and resolve faults, ensuring the equipment runs smoothly and efficiently.

Categories Recycling News

Posted on

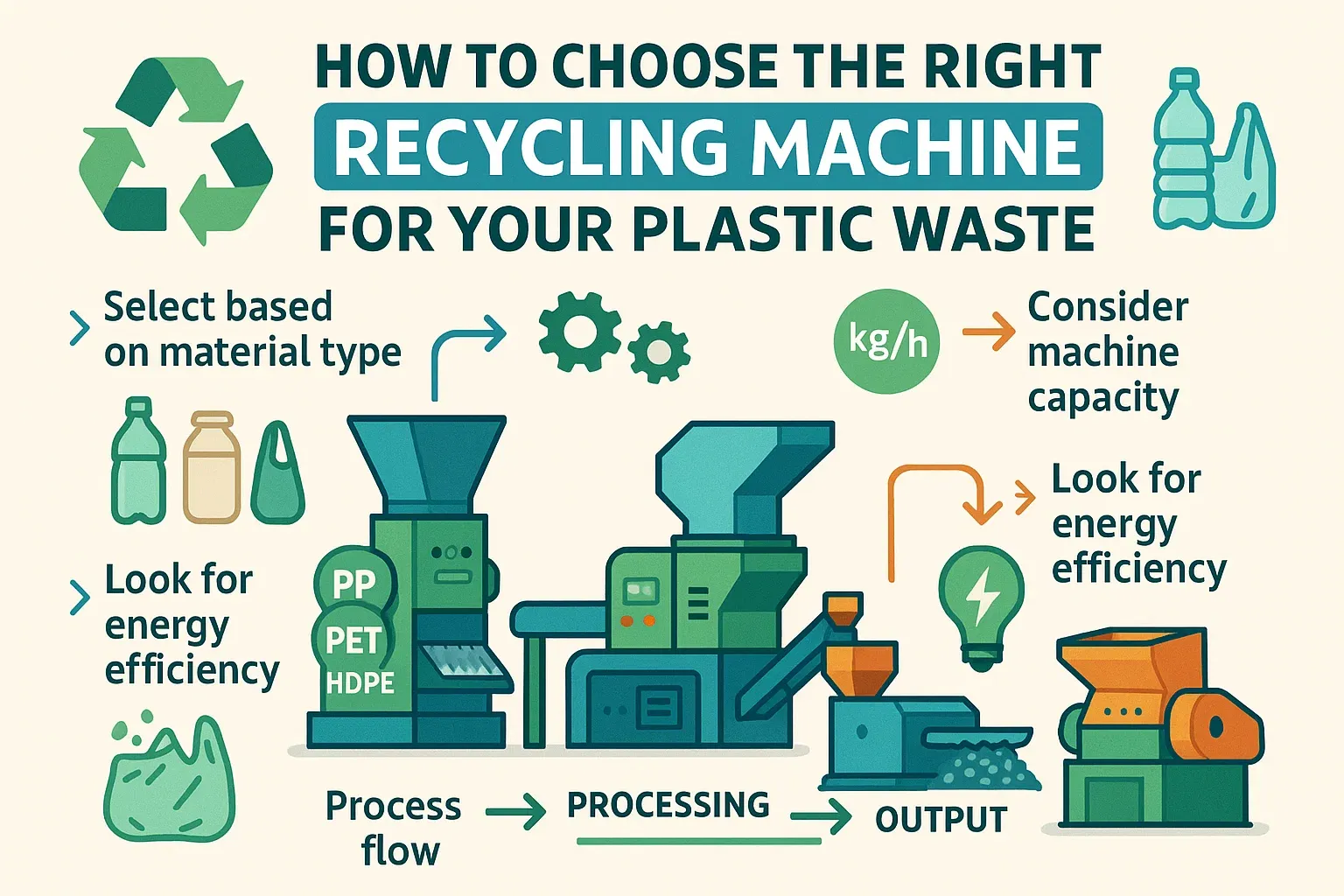

Discover how to select the right recycling machine for your plastic waste. This comprehensive guide provides insights for industrial equipment purchasers, engineers, and technical personnel to choose the most efficient and cost-effective recycling machines for various plastic types.

Categories Recycling News

Posted on

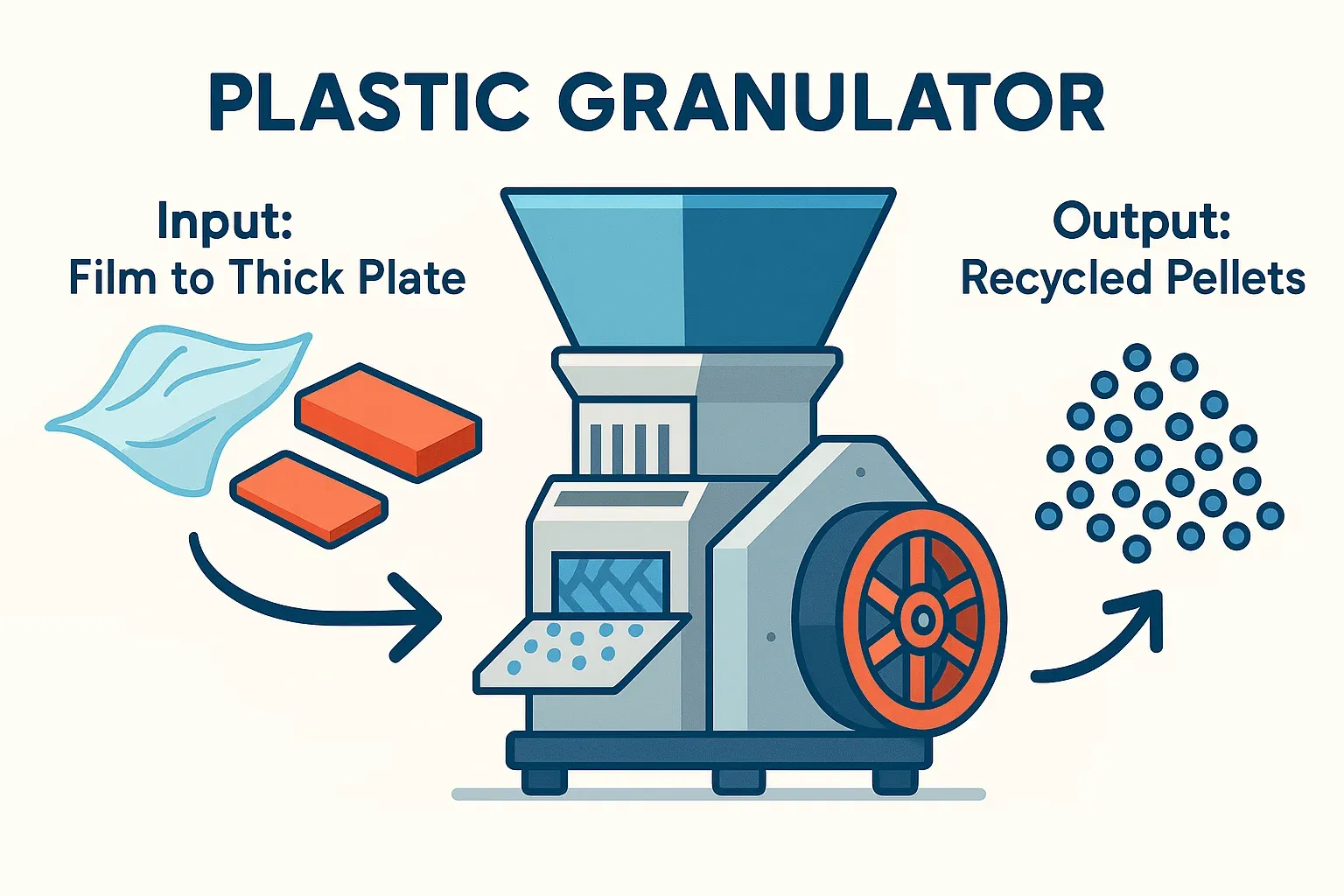

Discover the crucial role of plastic granulators in the growing plastic recycling industry. This guide covers their wide-ranging applications, detailing how different granulator designs effectively process materials from thin packaging films to thick industrial sheets and purgings. Understand key selection factors for buyers, engineers, and technicians to optimize plastic waste size reduction and contribute to a circular economy.

Categories Recycling News

Posted on

Selecting a reputable supplier for your plastic centrifugal dryer is critical for efficiency, reliability, and managing total cost of ownership. This comprehensive guide helps industrial buyers, engineers, and technicians evaluate potential suppliers based on technical expertise, product quality, customization, after-sales support, and more, ensuring you make an informed investment for your plastic processing line.

Categories Recycling News

Posted on

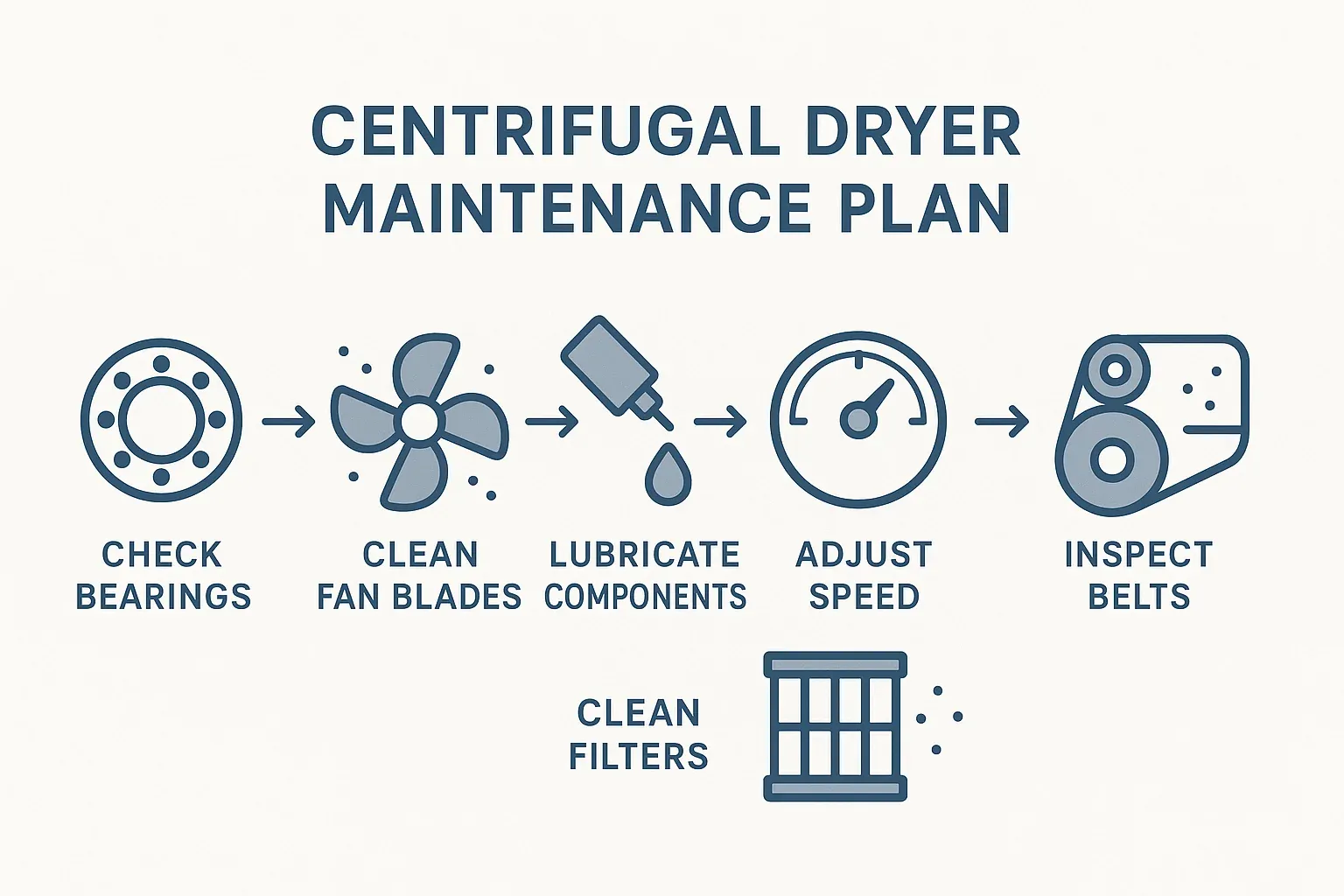

Ensure optimal performance and longevity of your industrial centrifugal dryer with this detailed maintenance plan. Covers essential daily, weekly, and monthly inspection tasks, lubrication protocols, troubleshooting common issues like vibration and overheating, crucial safety precautions, and the importance of record-keeping. A practical guide for maximizing uptime and efficiency.

Categories Recycling News

Posted on

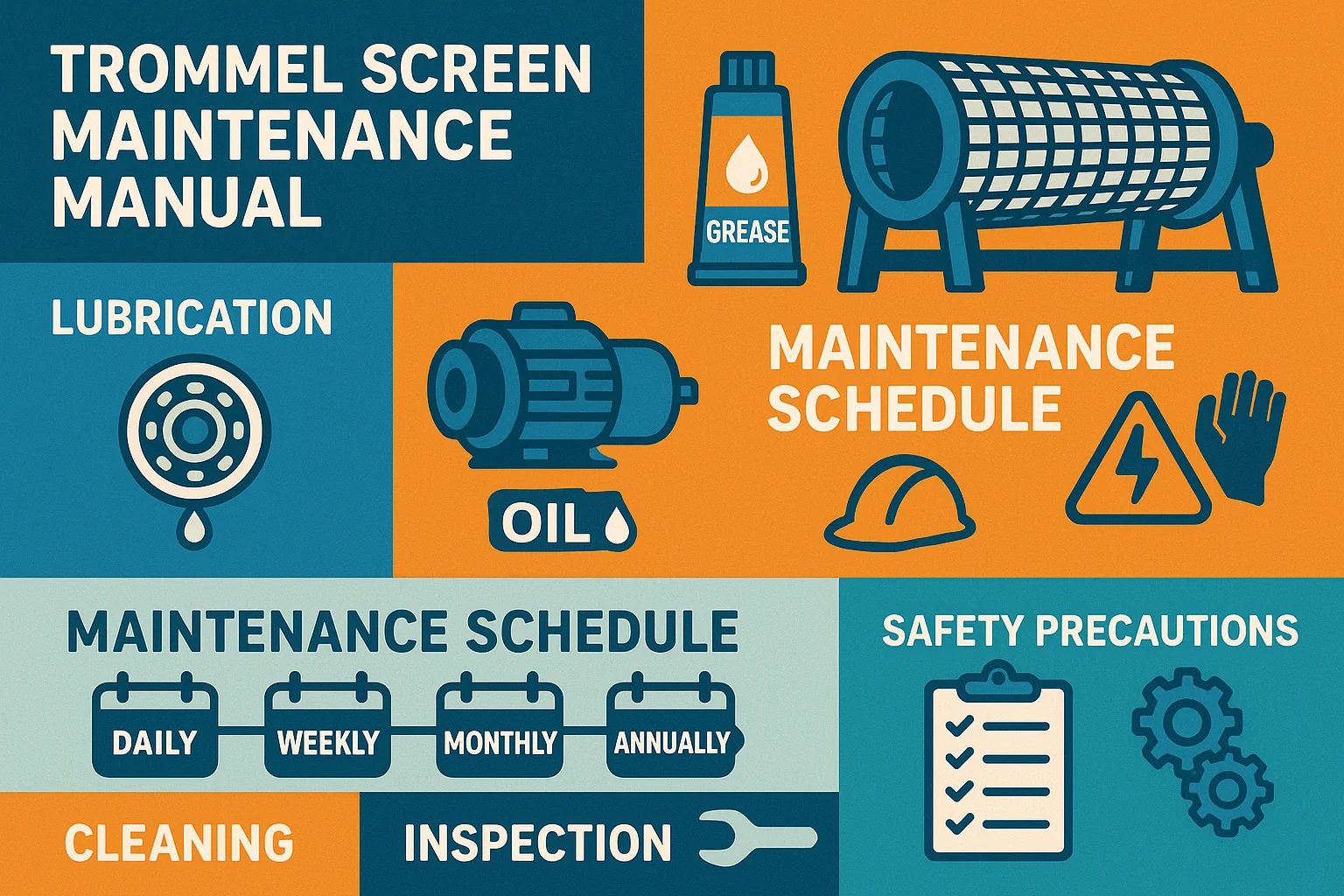

This Trommel Screen Maintenance Manual provides essential guidelines on lubrication, maintenance schedules, and safety measures to keep your equipment running efficiently and safely.

Categories Recycling News

Posted on

Explore the world of PET Recycling Machines in this comprehensive guide. Understand how these machines work, the various types available, their environmental benefits, and the diverse applications of recycled PET.