Recycling News

Introduction

Polyvinyl Chloride (PVC) is widely used in construction, automotive, and consumer goods due to its durability, versatility, and cost-effectiveness. With increasing environmental awareness and regulatory pressures, recycling PVC has become essential to reducing waste and conserving resources. The two primary recycling methods—mechanical recycling and feedstock recycling—are essential for handling both straightforward and complex PVC waste streams.

Why PVC Profile Recycling Matters

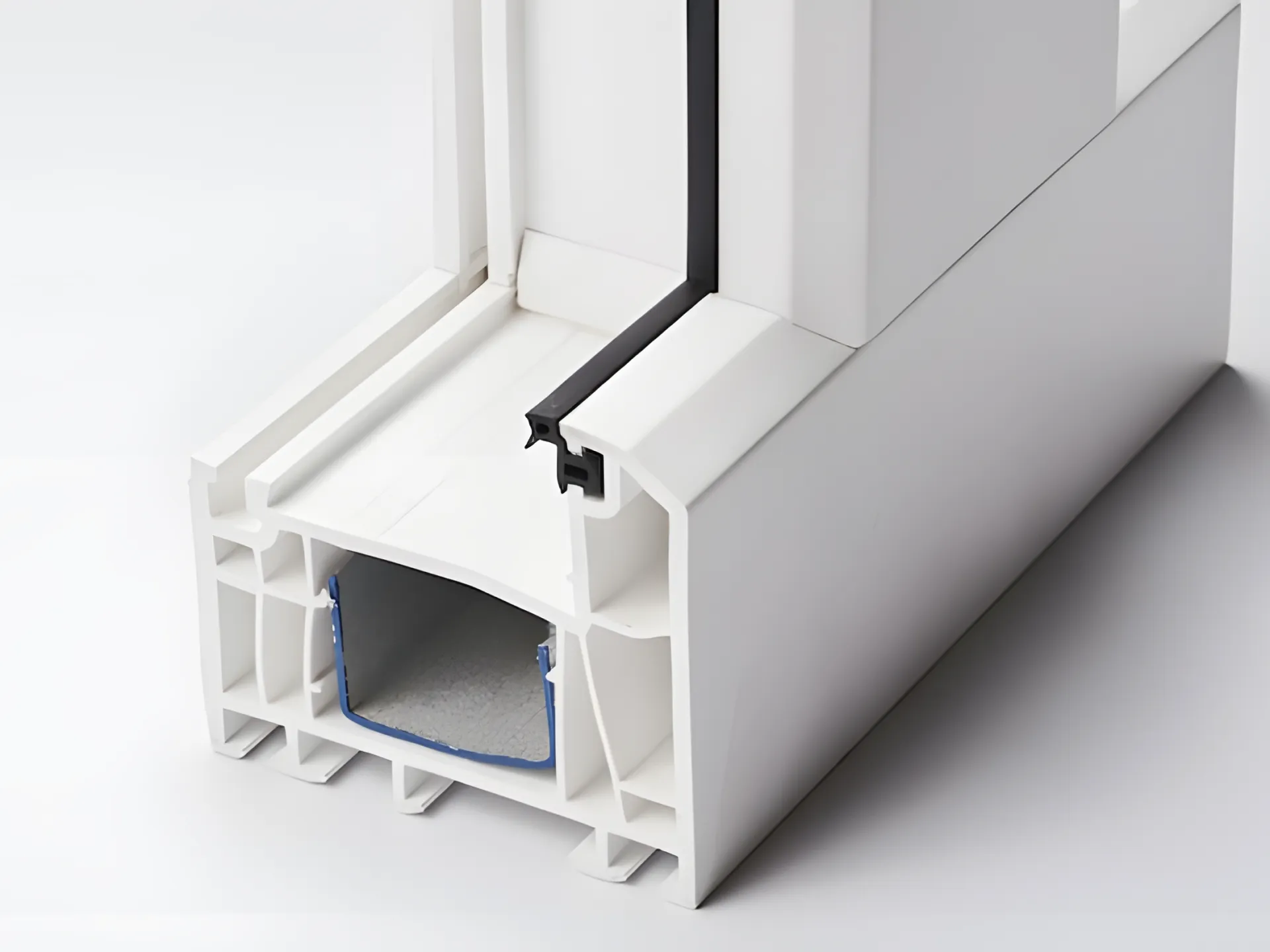

Recycling PVC profiles, especially through advanced machinery, is essential for reducing waste, saving resources, and supporting a circular economy. PVC, or polyvinyl chloride, is widely used in construction for products like windows and doors. When companies like Deceuninck recycle these profiles, they extend the lifespan of PVC materials, reduce environmental impact, and preserve the quality of the products.

The European Union has introduced new restrictions on lead usage in PVC (polyvinyl chloride) products, aimed at minimizing human exposure to this hazardous substance. The updated regulation, adopted on May 3, 2023, amends Annex XVII of the REACH Regulation (EC No. 1907/2006) and sets clear guidelines for the use and marketability of PVC products containing lead.

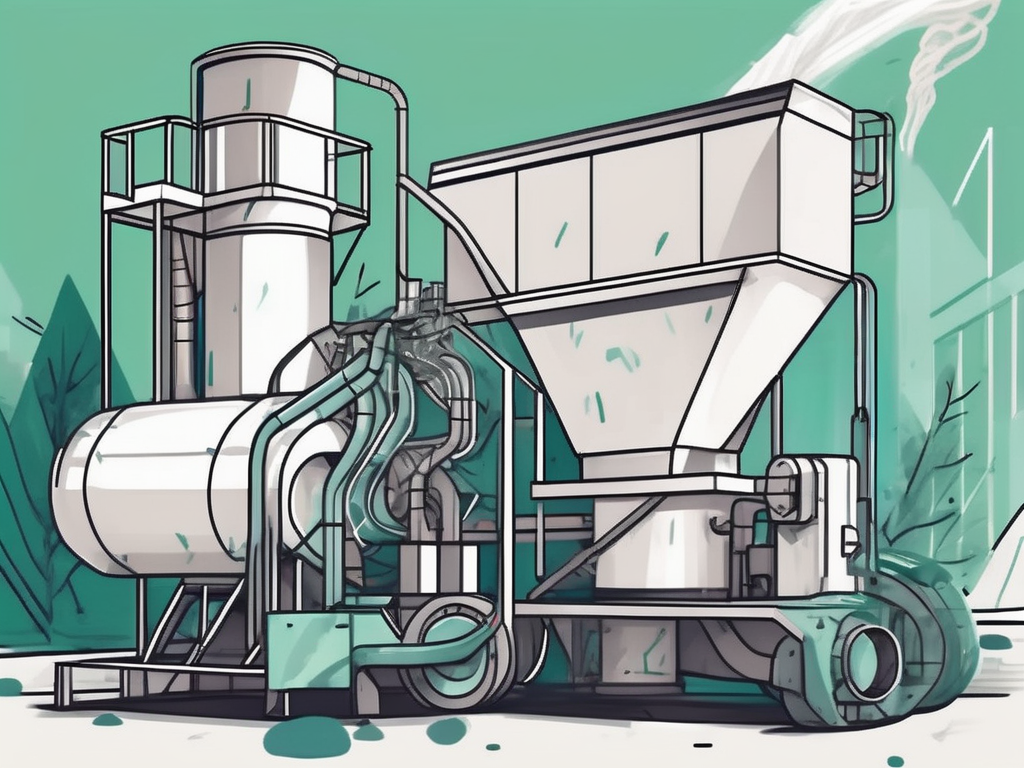

In the plastic recycling industry, wet plastic grinding machines have become essential due to their superior performance and environmental benefits. These machines are specifically designed to process various plastics by integrating water into the grinding mechanism, resulting in enhanced efficiency and reduced operational issues.

In the world of plastic manufacturing, waste management is no small affair, and the introduction of PVC pipe horizontal crushers has been nothing short of a game-changer. Let’s dive deep into how these robust machines are making significant strides in transforming the industry’s approach to waste.

In the bustling world of industrial manufacturing and recycling, efficiency isn’t just a goal—it’s a necessity. PVC pipe horizontal crushers are at the forefront of this, transforming waste management practices across various industries. Let’s break down how these crushers enhance operational efficiency, demonstrate versatility, and ultimately prove to be cost-effective solutions for businesses.

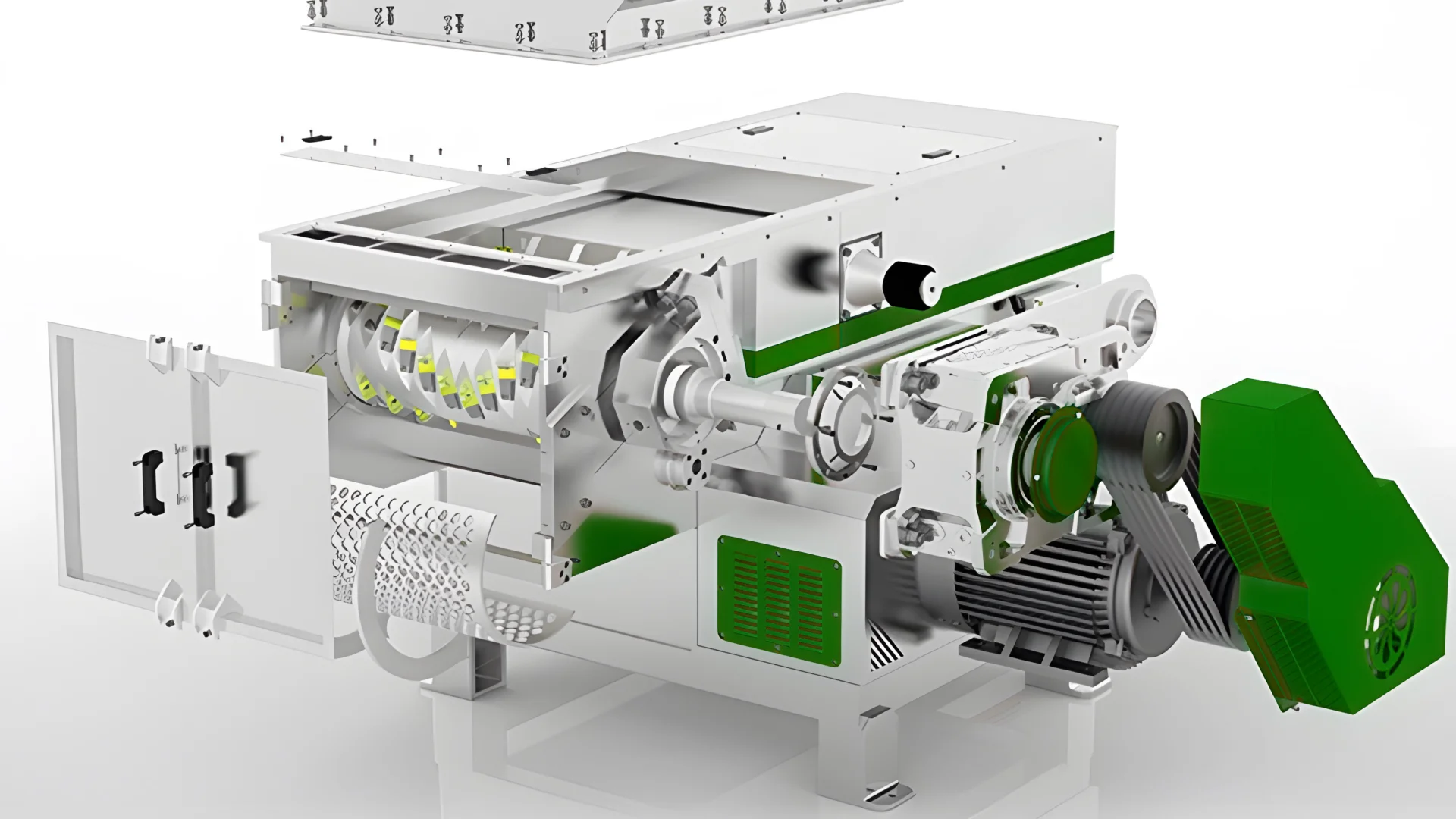

Proper maintenance is crucial for the longevity and efficiency of industrial machinery. A Single Shaft Shredder is no exception. This versatile equipment, essential in waste management and recycling operations, demands regular attention to keep it running smoothly. Let’s dive into the essential maintenance tips, the importance of regular upkeep, and common pitfalls to avoid.

Dealing with operational issues in heavy machinery can be daunting. A Single Shaft Shredder is no exception. This versatile equipment, crucial for effective waste management and recycling operations, sometimes encounters technical problems that can hinder its performance. This article will guide you through troubleshooting common issues, ensuring your shredder operates at peak efficiency.

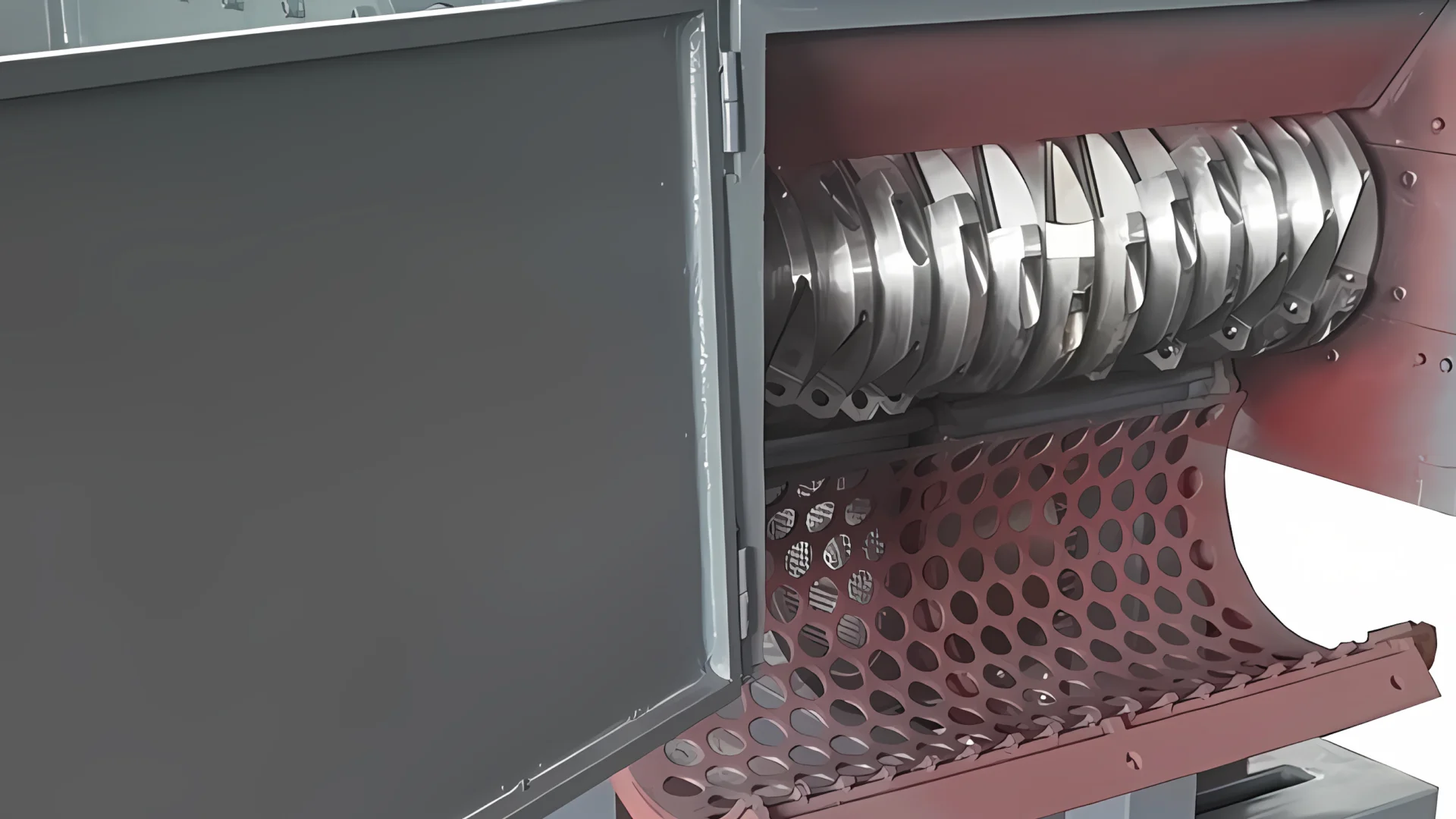

Understanding the intricacies of a Single Shaft Shredder can be crucial for those operating in recycling or waste management industries. This type of shredder plays a pivotal role in the size reduction of various materials, making its components integral to its function. Let's delve into the key components that define its efficiency and effectiveness.

Ensuring the longevity of your Single Shaft Shredder is crucial for maximizing its performance and efficiency in waste management and recycling operations. This blog post will explore six strategic ways to extend the lifespan of your shredding equipment, from routine maintenance to avoiding operational errors.