Recycling News

The two-stage PP PE pelletizing system is designed to handle film regrinds from a washing plant. It comprises two sets of single screw extruders to ensure the final product is of superior quality. Final products generated by this pelletizing system are in the form of pellets/granules and can be directly used in the production line for film blowing, pipe extrusion, plastic injection, etc.

This two-stage HDPE flakes pelletizing system consists of two sets of single screw extruders and integrates the function of feeding, plasticization, and pelletizing into a single step. The final product generated by this pelletizing machine are high-grade pellets/granules (see additional images below) that can be directly put into plastic injection machines or other applications.

Our twin-screw extruder is a high-velocity, co-rotating extruder perfect for your compounding requirements. Our robust extruders provide dependability in the most challenging tasks, such as the extrusion of plastics with high percentages of fillers, reinforcing fibers, or with heat-sensitive or shear-sensitive additives (such as flame retardants, glass fibers, etc.). You will find our twin-screw extruders to be highly advantageous in the production of rigid PVC and wood fiber blends.

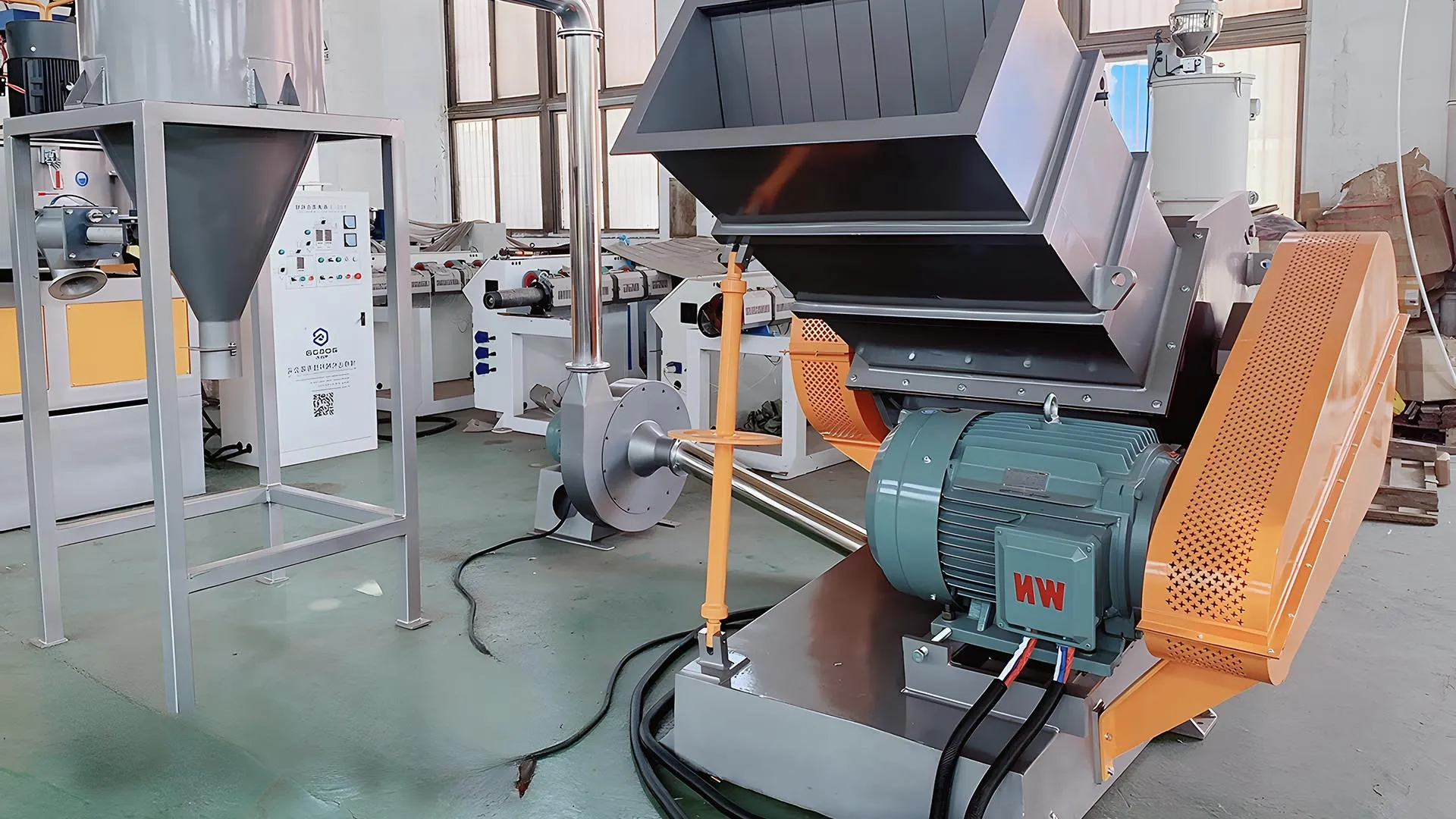

Our specialized extruded plastic granulator machines are engineered for granulating long pieces of rigid plastics for recycling such as pipes, sheets, boards, and other extruded profiles. It’s an optimal solution for crushing PP-R, PE, and PVC pipes that are challenging to insert into most plastic granulators.

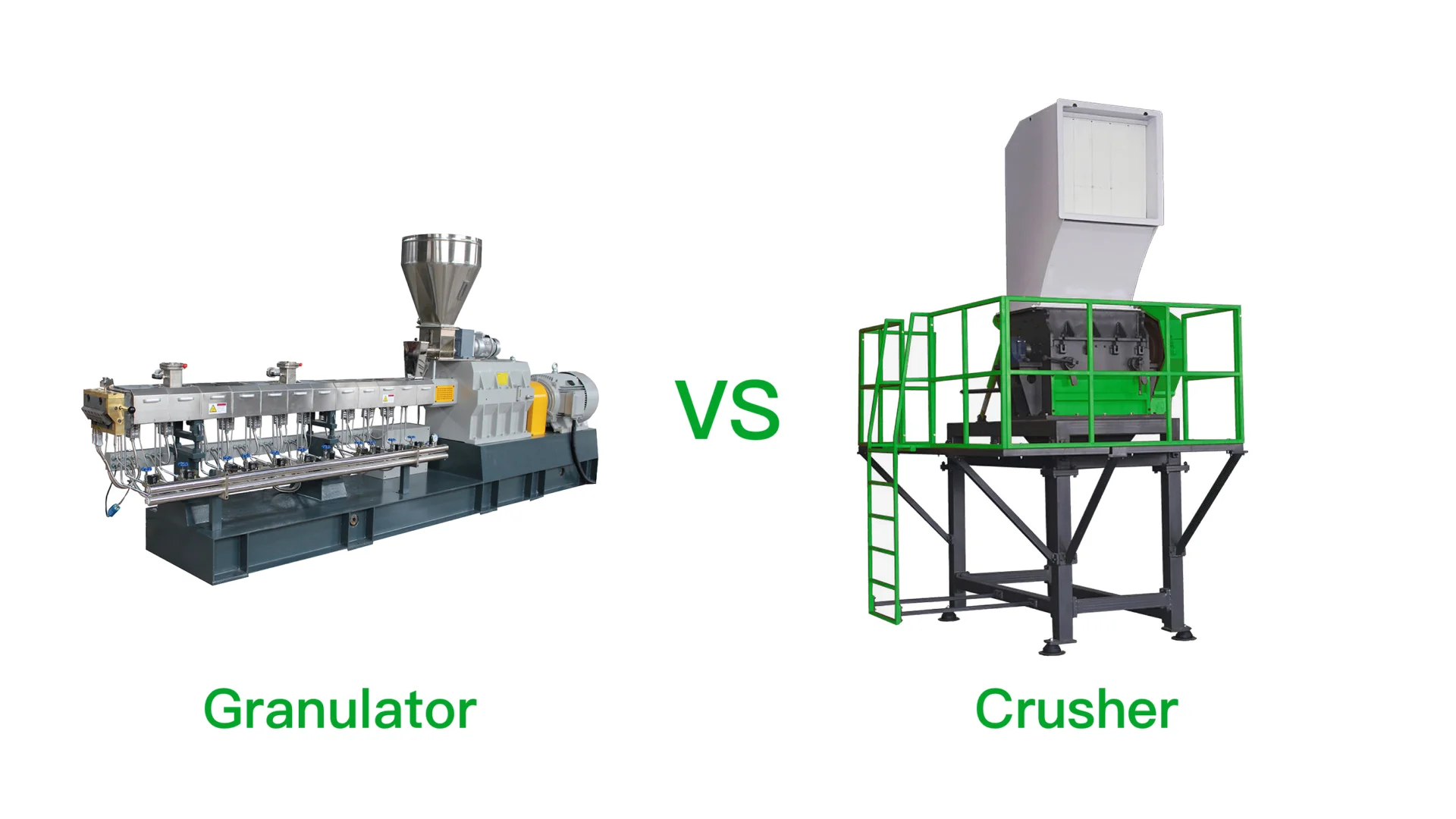

Decoding the Crucial Tools in Recycling Operations

In the fast-paced world of recycling, where efficiency meets innovation, the spotlight often lands on two heavyweight champions: plastic granulators and plastic crushers. As the push for sustainability gains momentum, understanding the roles and differences of these devices is not just useful—it's essential. Let's break down what these machines do, why they're important, and how they differ.

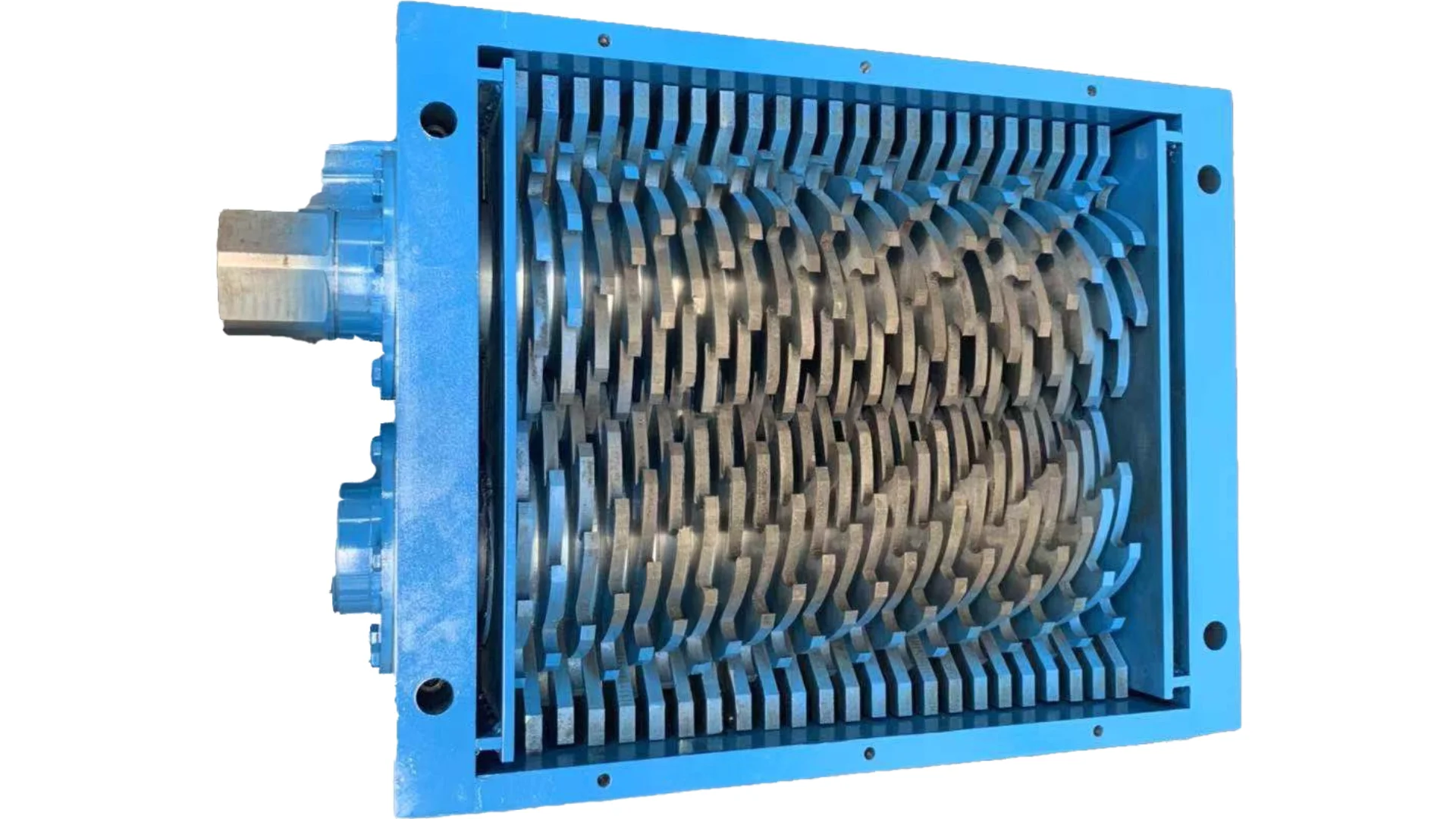

Industrial shredders come in a variety of types, each designed to handle specific materials and shredding requirements. Here’s a look at the main types of industrial shredders available in the market, highlighting their unique features and applications: