Recycling News

What is In-House Plastic Waste Recycling?

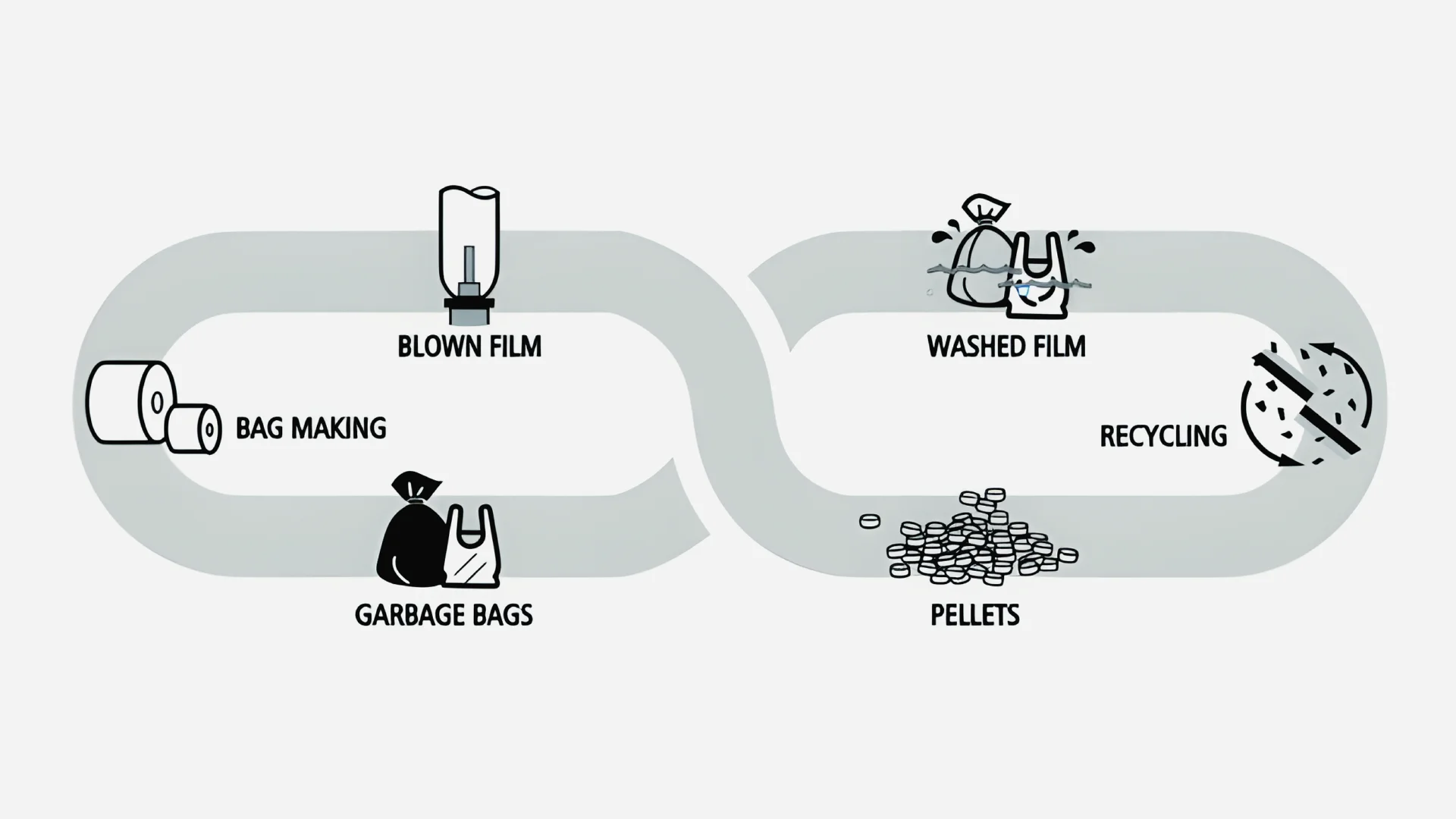

First, let’s talk about post-industrial recycling (PIR). This refers to the process of reprocessing plastic waste generated during the production of plastic products. When this recycling process takes place within the same manufacturing facility, it’s known as in-house recycling.

Types of Plastics for In-House Recycling

• PE plastic film on recycling machines

• Examples of post-industrial materials that can be recycled within the factory include plastic waste and defective materials generated during production. Common materials for in-house recycling are T-shirt bag scraps, HDPE/LDPE film and bag remnants, printed and unprinted plastic films, draw tapes, woven fabrics, blow molding waste, and injection molding waste.

Why Should Plastic Manufacturers Start Recycling In-House?

Many plastic manufacturers are already recycling production waste within their own facilities, reusing recycled pellets for production or selling them on the market. Given the global increase in polymer prices and resource shortages, manufacturers have realized that incorporating more recycled materials into production can not only reduce their carbon footprint but also cut costs.

Advantages of In-House Recycling

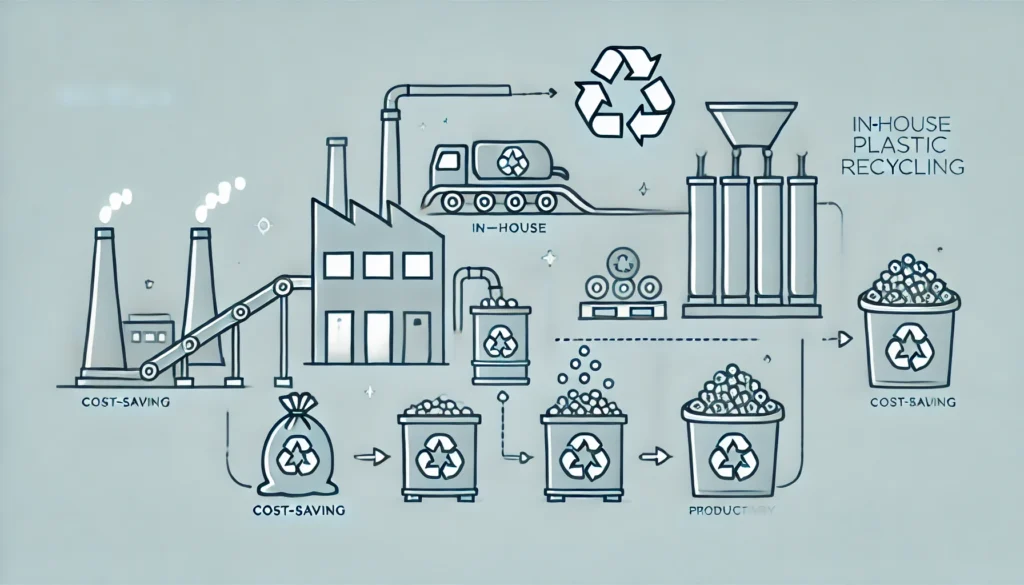

1. Cut Costs and Save Time

When manufacturers outsource their recycling to third parties, they face several preliminary steps, such as sorting valuable waste, storing it until they have enough, and transporting it to recycling facilities. Once the recycling process is complete, the pellets usually need to be transported back to the manufacturer’s plant. Additionally, manufacturers have to pay for these recycling services.

In-house recycling eliminates many of these steps, saving both time and money by avoiding logistics and outsourcing fees. It also gives manufacturers the flexibility to optimize their production and recycling processes, minimizing storage time and space.

2. Promote a Circular Economy

Using more recycled materials in products can lower production costs, reduce the carbon footprint, and minimize the use of raw materials. This is particularly important for manufacturers of films and bags that must comply with government regulations to increase recycled material content to sell in markets like Europe and the U.S. For these manufacturers, using their own waste to create post-industrial recycled material is one of the most efficient and cost-effective ways to obtain recycled resin.

3. Better Control Over Recycled Materials

To maximize recycling efficiency and achieve consistent quality, it is crucial to reprocess materials on stable recycling machines. Even when materials are made of the same polymer, their properties can vary, making it hard to distinguish without advanced tools.

By recycling in-house, manufacturers have complete knowledge of their material’s characteristics. This ensures that 100% of the recycled material, with consistent properties, can be directly reused on the production line, helping maintain strict quality control over the final products.

4. Boost Profitability

With rising polymer prices and increasing costs of raw materials, recycled resin is more valuable than ever. Even if manufacturers do not use 100% of their recycled pellets, they can sell the excess on the market, converting production waste into economic benefits. Legal and industry standards encourage the use of recycled content, creating a growing demand for recycled materials locally and globally. Applications such as injection molding, extrusion, and blow molding are ideal for using recycled pellets, which are often utilized to produce laundry detergent bottles, battery cases, broom fibers, pipes, furniture, toys, benches, recycling containers, and trash bins.

With the growing concern over plastic pollution, recycling PE (polyethylene) and PP (polypropylene) plastic film has become a critical component of environmental protection efforts. These films are commonly used in packaging, agriculture, and industrial applications, but they are notoriously difficult to decompose naturally after disposal. Therefore, understanding how to effectively recycle these materials is crucial.

In the vast universe of plastics, two stars shine with particular prominence: Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). These materials, omnipresent in our daily lives, from the bottles that hold our water to the bags that carry our groceries, possess unique characteristics that make them suitable for various applications. Yet, despite their common polyethylene ancestry, LDPE and HDPE exhibit distinct differences that define their roles in the world of materials. Let's embark on a journey to unravel the mysteries of LDPE and HDPE, shedding light on their similarities and differences, and understanding their significance in our modern world.

In today’s world, recycling is more important than ever, and one of the most significant materials we can recycle is PET (Polyethylene Terephthalate). PET is widely used in packaging, especially for beverages. However, without proper recycling methods, it can lead to environmental pollution. This is where the PET Recycling Machine comes into play. In this article, we will explore the ins and outs of PET Recycling Machines, their types, benefits, and how they work.

In the quest for a greener planet, the role of PET recycling machines has become increasingly pivotal. These machines not only embody the spirit of environmental stewardship but also represent a significant leap towards sustainable waste management. This comprehensive guide delves into the key components of a PET recycling machine, offering insights into the technology that's transforming the recycling industry.

The global market for Polyethylene Terephthalate (PET) resin is facing a wave of anti-dumping measures, predominantly targeting imports from China. With the EU, Korea, Mexico, and other nations introducing stringent duties and initiating investigations, the landscape for PET resin trade is rapidly changing. This article will dive into the specifics of these actions, exploring their implications for the PET industry, particularly focusing on China, which is at the center of these regulatory moves.

When it comes to recycling PET bottles, the granulator is a critical piece of machinery. Granulators transform PET bottles into small, manageable plastic flakes, which can be further processed and recycled. This comprehensive guide will walk you through everything you need to know about granulators for PET flakes—from how they work, their benefits, to tips on choosing the right one for your needs.

Understanding PET Bottle Recycling

What is PET Bottle Recycling?

For most people, PET bottle recycling simply means placing plastic bottles, such as water, soda, or oil bottles, into the blue recycling bin or dropping them off at a nearby recycling center. While these actions are an important part of the process, there's much more that happens before these bottles can be fully recycled and transformed into new products like polyester fibers, PET sheets, or even back into PET bottles.

The Importance of Proper Recycling

Proper PET bottle recycling is crucial for reducing waste, conserving resources, and minimizing environmental impact. By understanding the full recycling process, individuals can better appreciate the importance of correctly sorting and recycling their plastic bottles, ensuring they are transformed into valuable new products instead of ending up in landfills.

Collecting PET Bottles

Curbside Recycling

The first critical step in PET recycling is the collection of bottles. A large portion of this collection is done through curbside recycling programs, where trucks pick up recycling bins from homes, or via drop-offs at local recycling centers.

Recycling Center Drop-Offs

In curbside programs, also known as "single-stream" recycling, all recyclables are placed in a single bin and transported to a materials recovery facility (MRF) for sorting. This mixed stream includes items like glass, aluminum cans, plastic bottles, and paper/cardboard, which are sorted both manually and by machines.

Sorting and Preparing for Recycling

Once collected and sorted at the MRF, the plastic bottles are compacted into large bales and sent to a PET bottle washing plant, either locally or abroad, where they begin the transformation into "hot-washed" PET flakes. Meanwhile, other recyclables like glass, metals, and paper are sent to their respective facilities for further processing.

PET Bottle Washing and Recycling Process

Step 1: Debaling and Sorting

When the PET bottles arrive at the recycling plant, they are typically in large, compacted bales that have already been sorted by color. The goal of the PET bottle washing plant is to thoroughly clean these bottles so they can be reused, while also removing contaminants like labels and caps, which are not made from PET plastic.

The recycling process begins with a debaling machine that breaks apart these large bales, allowing the bottles to flow freely onto a conveyor belt that leads to a trommel, a large rotating tunnel that removes small contaminants like glass, metals, and paper. After passing through the trommel, the bottles move on to manual sorting, where workers remove any remaining non-PET items.

Step 2: Washing and Contaminant Removal

The next step is cutting the PET bottles into small pieces, known as "PET flakes," using a granulator. As these flakes are cut, water is sprayed onto them, beginning the washing process. The flakes are then subjected to an air classifier, which separates lighter materials like plastic film labels from the heavier PET plastic. Following this, the flakes enter a float/sink separation tank, where PET flakes sink while caps made from polypropylene or polyethylene float, allowing for easy separation.

Once most contaminants have been removed, the PET flakes are subjected to a hot washer, which uses hot water and a caustic solution to remove remaining impurities like glue, grease, and leftover liquids. A cold friction washer provides additional scrubbing, leaving the PET flakes perfectly clean.

Step 3: Drying and Preparing PET Flakes

Before PET flakes can be reused, they must be thoroughly dried to avoid air bubbles during the melting process. This involves using a de-watering machine, which spins away excess water, followed by a dehydration process with thermal heaters that reduce the moisture content to below 1 percent. The result is clean, dry PET flakes, ready for manufacturing.

What Happens to Recycled PET Bottles?

From PET Flakes to New Products

Now that we have clean PET flakes, they can be transformed into various new products. The most common use of these flakes is in the production of polyester staple fibers, which are woven into clothing, carpets, and other textiles.

Applications of Recycled PET (RPET)

Recycled PET (RPET) can also be used to manufacture PET sheets, boards, strapping, and thermoformed products like laundry scoops. Additionally, RPET can be used in engineering applications, such as reinforced components for automobiles, or even remanufactured into new PET bottles through a process called "pelletizing," where the flakes are melted, shaped into pellets, and then used in injection molding or other manufacturing processes.

FAQ

Q1: What is PET plastic, and why is it important to recycle it? A1: PET, or polyethylene terephthalate, is a type of plastic commonly used in bottles and packaging. Recycling PET helps reduce waste, conserves resources, and supports the production of new materials like polyester fiber.

Q2: How are contaminants removed from PET bottles during recycling? A2: Contaminants like labels and caps are removed through a combination of manual sorting, air classifiers, and float/sink separation tanks during the recycling process.

Q3: What products can be made from recycled PET? A3: Recycled PET can be used to create polyester fibers for clothing, PET sheets, packaging materials, and even new PET bottles through an extrusion process.

Q4: How does PET recycling benefit the environment? A4: PET recycling reduces the amount of plastic waste in landfills, conserves natural resources, and decreases the environmental impact of producing new plastic materials.

Conclusion

PET bottle recycling is a complex but essential process that goes beyond just placing bottles in a recycling bin. Through various stages of collection, sorting, cleaning, and processing, these bottles are transformed into valuable new products, contributing to a more sustainable and eco-friendly future.

What is a Centrifugal Dryer Dewatering Machine?

A centrifugal dryer dewatering machine is a specialized piece of equipment designed to remove excess moisture from polyethylene plastic materials. Using high-speed spinning, these machines efficiently separate water from plastic particles, making the drying process faster and more efficient.

In the world of recycling and manufacturing, the Plastic Granulator plays a crucial role. This machine is designed to break down plastic waste into smaller pieces, known as granules, which can then be reused in various applications. With the increasing focus on sustainability and waste reduction, understanding how plastic granulators work and their importance in the recycling process is essential for businesses and individuals alike.