Recycling News

Used recycling equipment can be a cost-effective solution for businesses looking to enhance their recycling operations without overspending. Whether you’re running a small recycling center or need additional machinery for industrial purposes, buying second-hand equipment offers both financial and environmental benefits. Here’s a practical guide on what to consider when searching for used recycling equipment for sale nearby.

1. Benefits of Buying Used Recycling Equipment

Cost Savings: Used equipment costs significantly less than new machinery, allowing you to allocate your budget elsewhere. This is particularly important for small businesses or startups.

Sustainability: By purchasing second-hand, you’re contributing to the circular economy and reducing the demand for new manufacturing.

Immediate Availability: Pre-owned equipment is often ready for pickup or delivery, reducing lead times compared to ordering new units.

2. What to Look for When Buying Used Recycling Equipment

Condition of the Equipment: Examine the machinery for wear and tear, rust, or any visible damage. If possible, request maintenance records to verify its operational history.

Compatibility: Ensure the equipment matches your facility’s requirements and integrates seamlessly with your existing processes.

Functionality Testing: Before purchasing, test the equipment to confirm it performs as expected. Many sellers will offer a demonstration.

Brand Reputation: Opt for well-known brands with a history of durability and reliability. This ensures you can find spare parts and support more easily if needed.

Seller Reputation: Buy from trusted sources. This includes certified dealers, auctions, or reputable recycling facilities offering surplus equipment.

3. Where to Find Used Recycling Equipment Nearby

Local Recycling Centers: Contact recycling businesses in your area. Many upgrade their machinery and sell their older models.

Online Marketplaces: Check websites that specialize in industrial equipment sales, such as Machinio, Recycler’s World, or eBay for Business. Filter results to your location to find equipment nearby.

Equipment Dealers: Many dealers offer both new and used recycling machinery. They often provide warranties or after-sales services.

Auctions: Industrial equipment auctions are excellent for finding well-maintained used machinery at competitive prices. Look for both online and in-person auctions in your area.

Networking: Reach out to local industry groups, trade associations, or forums where recycling professionals share information about equipment sales.

4. Types of Recycling Equipment Commonly Available

Depending on your needs, here are some commonly found used recycling machines:

• Balers: Compress recyclables like cardboard and plastic into compact bales.

• Shredders and Crushers: Process items like glass, wood, and plastic.

• Conveyor Systems: Transport materials efficiently through your facility.

• Sorting Machines: Separate recyclables by material type or size.

• Granulators: Break down plastics into smaller, reusable particles.

5. Why Work with a Trusted Dealer

Buying from a trusted dealer ensures that you receive reliable equipment with accurate descriptions. Many dealers inspect, refurbish, and test machinery before selling. They may also offer warranties or ongoing maintenance plans. To connect with a reputable seller, consider reaching out through a trusted source. For example, you can contact Rumtoo Machinery to inquire about used recycling equipment for sale and learn about their offerings.

6. Final Tips for Buying Used Recycling Equipment

• Negotiate Pricing: Used equipment prices are often negotiable. Don’t hesitate to ask for discounts or added value such as free delivery.

• Inspect Documentation: Verify that the equipment isn’t stolen or encumbered with liens.

• Plan Transportation: Arrange logistics for moving large machinery to your site.

By following these steps, you can find high-quality used recycling equipment that meets your operational needs while staying within budget.

What is a Waste Tire Granulator?

A waste tire granulator is a specialized industrial machine designed to recycle scrap tires by breaking them down into smaller, reusable pieces known as rubber granules. These granules, which typically range from 1 mm to 20 mm in size, can be used across a variety of industries. The granulator is a crucial part of tire recycling processes, helping convert bulky waste into valuable resources that can be reused in different applications.

The global challenge of plastic waste has necessitated innovative solutions in recycling technology. One of the most groundbreaking advancements is the integration of Artificial Intelligence (AI) into the sorting and processing of plastics. AI technologies are transforming the recycling industry by enhancing efficiency, accuracy, and the overall quality of recycled materials.

Industries worldwide—from petrochemicals to pharmaceuticals—rely on feeders to control the flow of bulk materials in their processes. However, the behavior of dry bulk solids varies significantly depending on their chemical and physical properties, making material handling a complex challenge. This guide explores how understanding material characteristics and choosing the right feeding technology can improve process efficiency and product quality.

The total shipment value of primary plastics machinery in North America reached an estimated $319.0 million in Q3 2024, marking a 41.9% rise compared to the previous quarter.

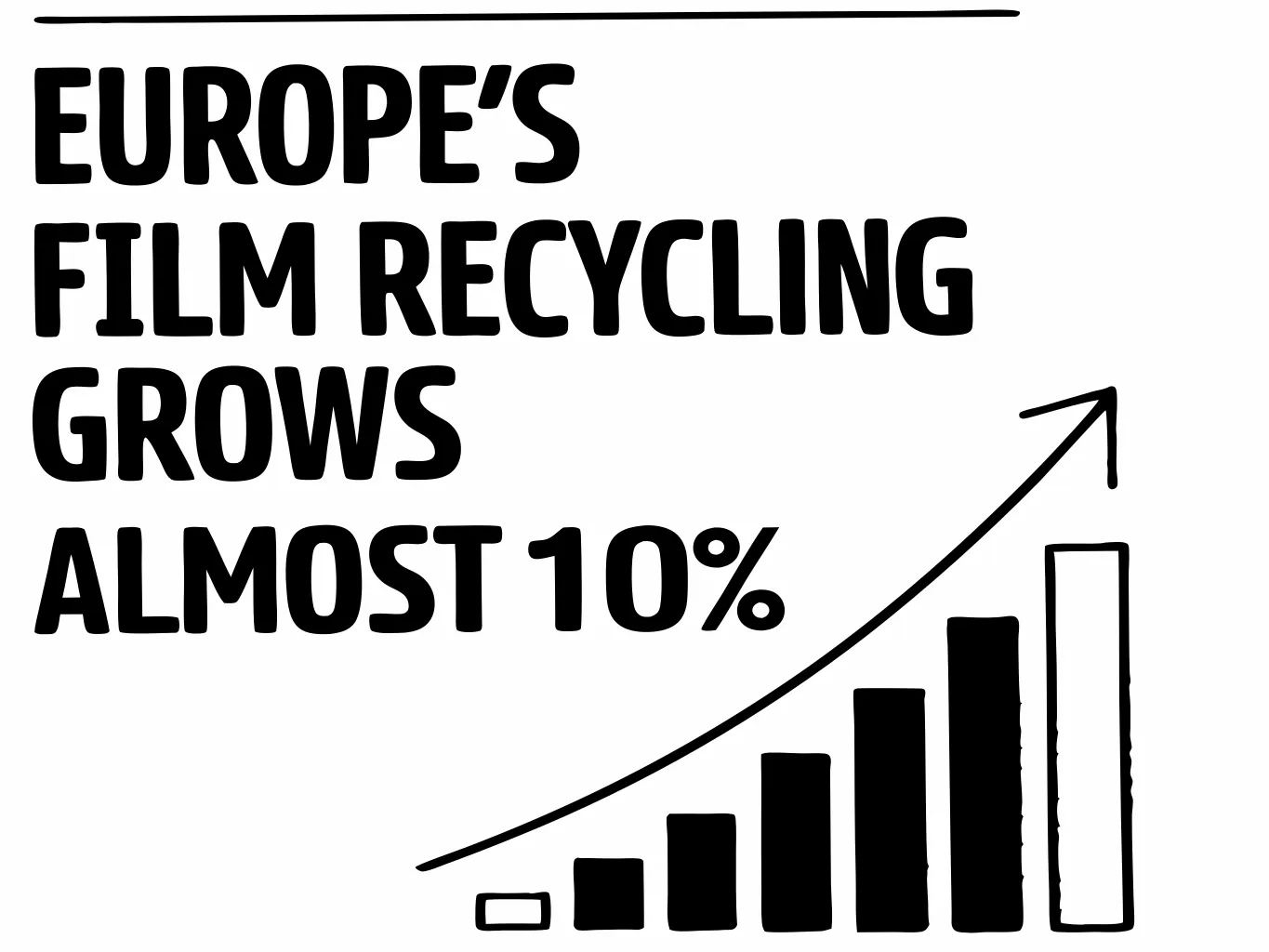

Despite the significant disruptions in waste management due to the COVID-19 pandemic, Europe's recycling capacity for flexible film surged by nearly 10% in 2020. According to Plastics Recyclers Europe, this growth highlights the region's leadership in mechanical film recycling and its commitment to advancing a circular economy.

The Nigerian plastic recycling market has seen significant growth over the years, driven by increasing awareness of environmental issues, government initiatives, and the economic potential of recycling. Here's a breakdown of its current status, processes, and implications:

Rigid plastics, encompassing materials like HDPE, LDPE, PET, and PVC, are integral to various industrial applications, from consumer packaging to automotive parts. Recycling these materials not only helps in conserving resources but also significantly reduces landfill waste and environmental pollution. This guide aims to explore the high-performance recycling equipment designed specifically for processing rigid plastics, providing insights into how these machines work, why they are essential, and what to consider when selecting the right equipment for your operation.

Maintaining PVC recycling machinery is vital for ensuring optimal performance, extending equipment longevity, and producing high-quality recycled products. Below is a detailed guide on best practices for maintaining PVC recycling machinery effectively.

Vinyl siding is widely used for its durability and low maintenance, but what happens when it reaches the end of its life? Recycling is a sustainable solution, and with the aid of vinyl recycling machines, the process becomes even more efficient. This guide will walk you through the essentials of vinyl siding recycling, including the role of specialized machines in making the process easier and more environmentally friendly.

PVC (polyvinyl chloride) is a widely used plastic in construction, packaging, and consumer goods. Recycling PVC can mitigate environmental harm and provide economic benefits, but it requires specialized equipment. Below is a structured cost-benefit analysis to help evaluate the investment.

What is Automotive Plastic Parts Recycling?

Automotive plastic parts recycling involves the process of reclaiming and reusing plastic components from vehicles. With the increasing emphasis on sustainability, recycling automotive plastics not only helps in managing waste but also in conserving resources.