Recycling News

Maximizing efficiency in PET (polyethylene terephthalate) recycling is essential for reducing environmental impact and enhancing operational productivity. To achieve this, consider the following strategies:

Rigid plastic recycling machines are pivotal in transforming waste plastics into valuable raw materials for manufacturing, contributing to both environmental sustainability and economic efficiency. Below is an in-depth look at the key components, functionalities, and benefits of these machines, along with guidance on selecting the right equipment for your business.

Rigid plastics, including items like containers, bottles, and durable goods, form a significant part of plastic waste. Recycling these materials not only conserves resources but also reduces environmental impact. Here's how you can select the best machine for recycling rigid plastics:

Centrifugal dryers, often used in industrial settings for drying various materials, operate on a simple yet effective principle. These devices are crucial in processes where rapid and efficient drying is required, such as in the textile, chemical, and pharmaceutical industries. Here, we delve into how these machines function, why they are effective, and what makes them indispensable in industrial applications.

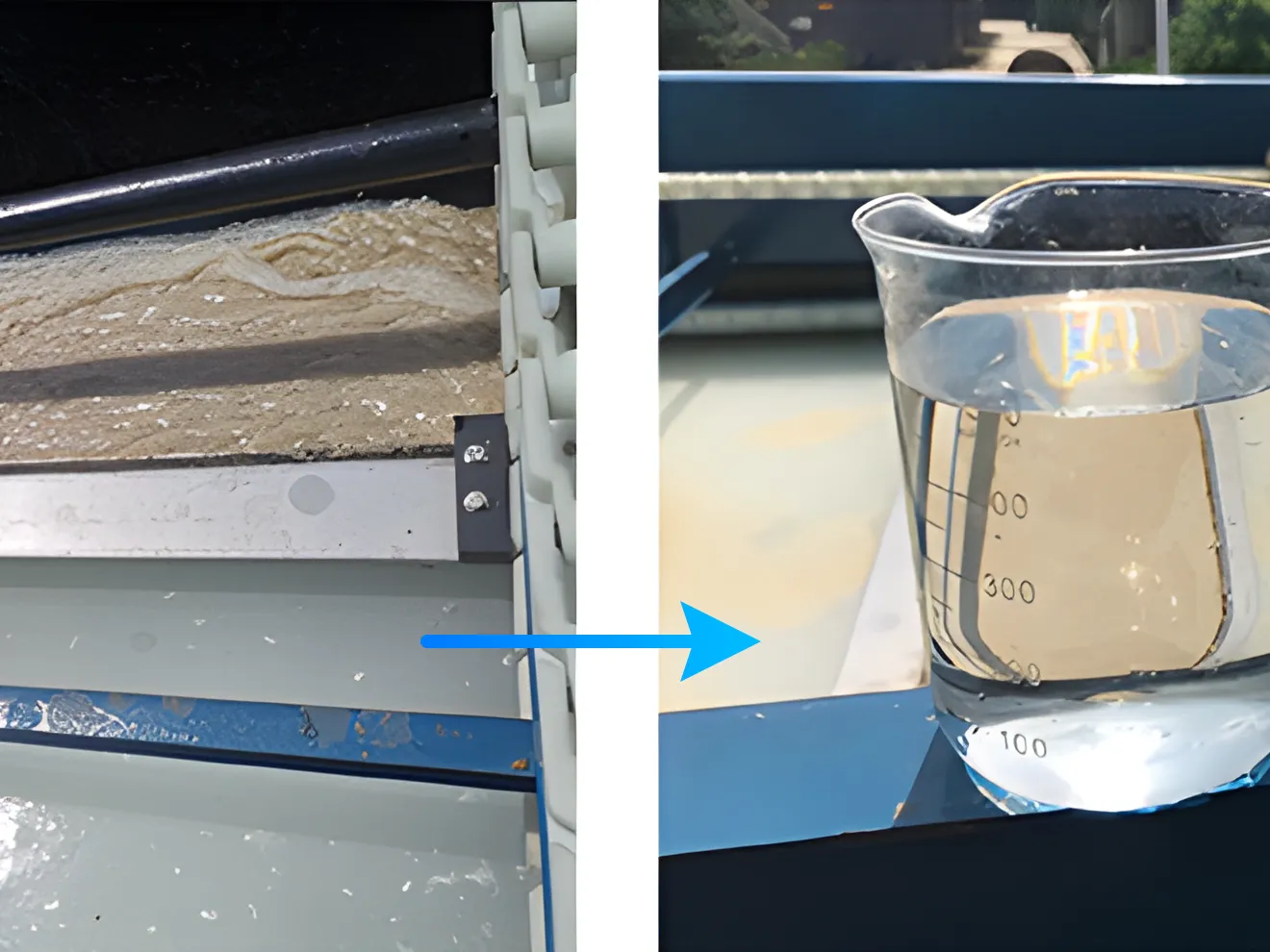

Wastewater from plastic recycling and washing is a major source of pollution in the plastic recycling and regeneration process, primarily originating from the cleaning, separation, and wet crushing of waste plastics. The concentration of pollutants in the wastewater is closely related to the characteristics of the raw waste plastics. For mixed, low-grade materials containing significant amounts of impurities such as paper and soil particles, the wastewater generation can reach up to 10 tons per ton of waste plastic. The wastewater produced during the cleaning and crushing stages contains high levels of organic matter and suspended solids, with chemical oxygen demand (COD) reaching up to 2000 mg/L and suspended solids (SS) up to 500 mg/L.

Introduction to PVC and Its Environmental Footprint

PVC, or Polyvinyl Chloride, is one of the most widely used plastics due to its versatility, durability, and cost-effectiveness. However, its lifecycle—from production to disposal—can have significant environmental implications. This article explores how recycling PVC can mitigate these impacts, focusing on reducing carbon footprints and managing plastic waste effectively.

Centrifugal dryers are instrumental in recycling operations, efficiently removing moisture from processed materials to enhance the quality and usability of recycled products. This guide explores how centrifugal dryers work, their advantages, and best practices for their maintenance.

When it comes to managing plastic waste efficiently, selecting the best rigid plastic recycling machine is crucial. The right machine not only reduces your environmental footprint but also boosts the efficiency and profitability of your recycling operations. In this comprehensive guide, we’ll walk you through all the key factors to help you make an informed decision.

Yes, foam can be recycled, but the process and feasibility depend on the type of foam:

A plastic centrifugal dryer is a specialized piece of equipment used primarily in the process of recycling plastics. Here's a detailed explanation based on common industry practices:

In the rapidly evolving world of recycling, rigid plastic recycling machines have seen groundbreaking advancements. These innovations are helping industries reduce waste, save costs, and improve efficiency. Let’s explore the top five game-changing technologies revolutionizing this field in 2024.

What does 'PVC' stand for?

Polyvinyl chloride. PVC is commonly referred to as vinyl, and the two names can be used interchangeably. Vinyl resin can be combined with a wide range of other materials such as plasticizers, stabilizers, lubricants, and colorants, depending on the requirements of the end product. Not all vinyl products use the same combination of materials.