Textile&Carpet Waste Single Shaft Shredder

An efficient piece of mechanical equipment designed to shred and process waste generated during production. By cutting and shearing materials, it increases the density of waste, making it easier to handle, store, and recycle.

Core Features

The shredder’s main shaft is crafted as a solid, integrated unit using CNC machining, ensuring there are no weld points. This enhances durability and structural integrity under heavy loads.

Equipped with an H-series reducer, the shredder operates at a reduced speed with higher torque. This feature improves cutting efficiency while maintaining operational stability.

The blades are made from high-strength D2 alloy steel that undergoes heat treatment. This makes them highly effective in cutting through various materials, including tough plastics, textiles, and light metals.

The reducer and main shaft are directly connected to minimize energy loss. Additionally, the reducer features built-in shock absorbers that mitigate buffer forces during operation, prolonging the machine’s life.

The shredder uses a PLC-controlled system with multiple safety features: Overload protection, automatic reverse functionality, and forward operation for continuous shredding.

The machine features a hydraulic system to power the material feed cart. It ensures smooth, steady feeding with consistent pressure, enhancing shredding precision and reducing manual labor.

Technical Specifications

The shredder’s specifications highlight its suitability for mid-scale applications, ensuring consistent and reliable performance:

Dimensions & Capacity

- Effective Rolling Knife Diameter: 300 – 420 mm

- Shredding Chamber Dimensions: 600 mm – 1450 mm

- Production Output: 300–1500 kg/h

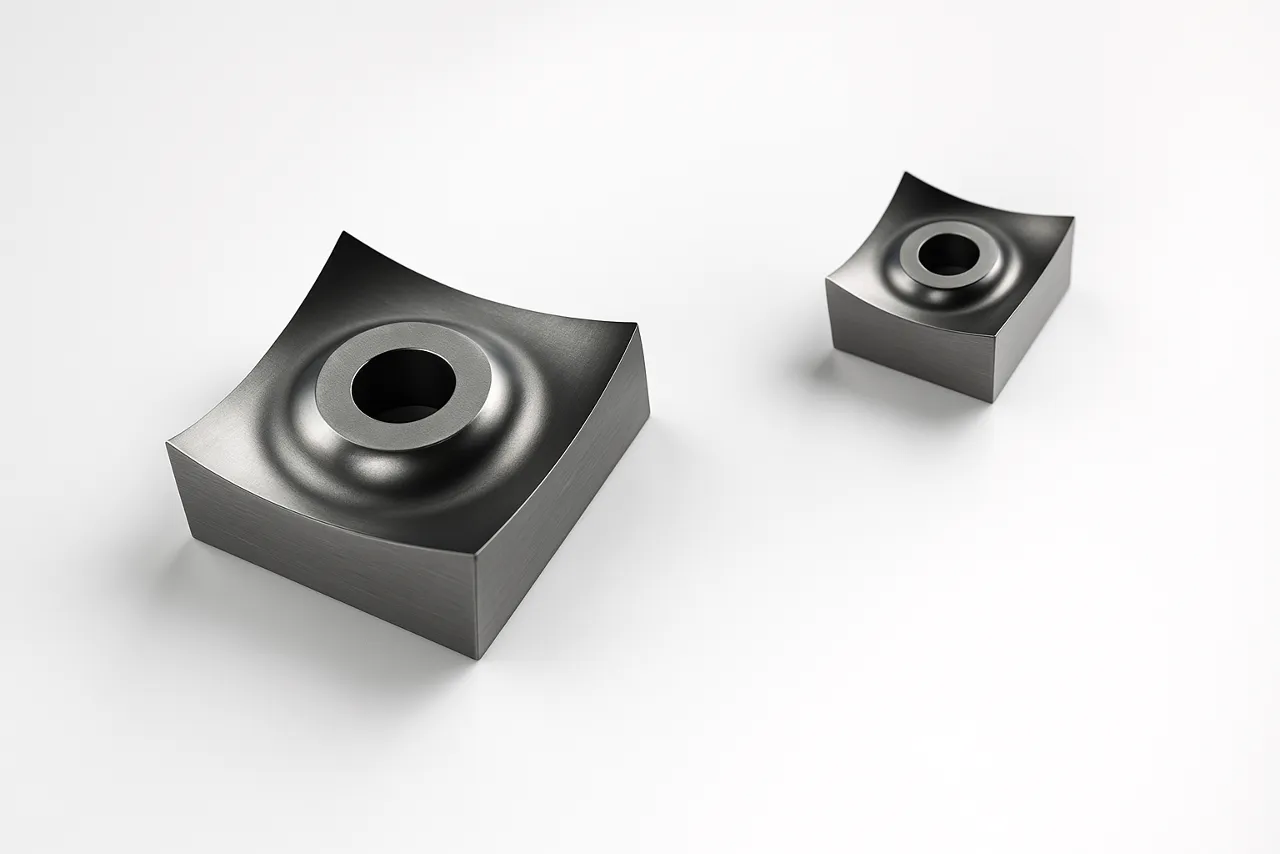

Blade Specifications

- Size(mm): 40×40、50×50、60×60

- Material: SKD-11、H13

- Fixed Blades Quantity: 4

- Rotating Blades Quantity: 30 – 68

Drive and Control System

- Motor Power: 30 – 90 kW

- Reducer Output Speed: 72 RPM

- Connection Type: Direct coupling

- Main Shaft: Solid, CNC-machined from 45-grade steel

Control Components

- PLC System: Delta

- Electronic Elements: Siemens contactors and overload protectors

- Buttons: Schneider

- Hydraulic Power: 3 – 6 kW

- Cooling Method: Air cooling

Key Benefits

Enhanced Durability

The solid, integrated design of the shaft and use of premium-grade materials for blades and walls provide superior resilience against wear and tear.

Improved Efficiency

With a production rate of 200–300 kg/h, the shredder processes waste rapidly, helping facilities streamline their recycling operations.

Operator Safety

Automatic overload protection and reverse functions safeguard both the equipment and the operator from unexpected issues.

Energy-Efficient Design

The machine’s direct-drive connection reduces energy loss, making it cost-efficient to operate over long periods.

Applications

Textile Industry

Cutting waste fabrics, offcuts, and threads for efficient disposal and recycling.

Plastic Recycling

Shredding films, bottles, and other plastic items for further processing.

Industrial Waste Management

Processing lightweight metals and other mixed materials for improved disposal.

Why Choose This Shredder?

This shredder is specifically engineered to handle tough operational demands with precision and efficiency. Its combination of robust construction, advanced control systems, and thoughtful design features makes it an essential tool for industries looking to reduce waste and improve recycling efforts. Investing in this machine not only enhances operational productivity but also supports sustainable waste management practices.

Ready to Optimize Your Waste Management?

Our textile waste single shaft shredder is the ideal solution for your industry’s recycling needs. Contact our team to learn more about specifications, pricing, and implementation.

Request a quote