Our Tire Recycling Machine offers advanced technologies to ensure maximum efficiency in the tire recycling process. Reduce your environmental footprint while generating revenue from recycled materials. Each feature focuses on enhancing productivity and safety, making it essential for businesses looking to embrace eco-friendly practices. Explore how our machine operates seamlessly to convert waste into useful resources.

Key Features

Key Components

Belt Conveyor

The Belt Conveyor, specifically designed for conveying large tire cuts, links various machines to facilitate continuous processes. It primarily comprises a motor, speed reducer, conveyor belt, roller, machine frame and blocking plate.

Tire Shredder

The Tire Shredder, used for shredding radial and fiber tires into 50x50mm chips in an ambient process, requires the tire to be debeaded before use. Its primary components include a motor, speed reducer, machine frame, shredding blades, rotary screener, and transmission system.

Belt Iron Separator

The Belt Iron Separator is utilized to isolate iron particles embedded in rubber granules, streamlining subsequent processing. Its primary components include an electromagnet, motor, conveyor belt, roller cylinder, machine frame and control cabinet.

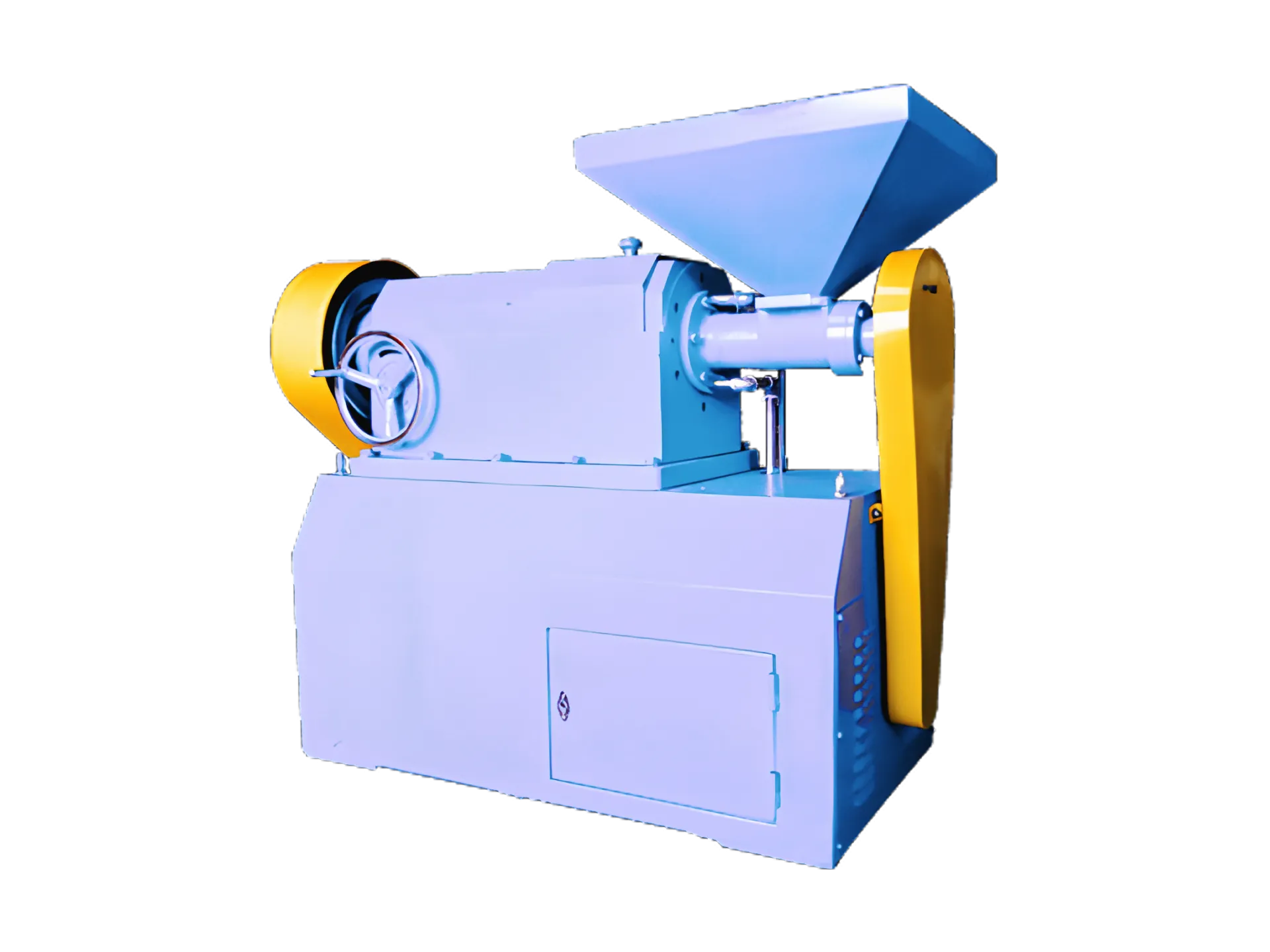

Double Roller Rubber Grinder

The machine comprises a main body, transmission, safety guard, roller temperature adjustment unit, lubrication system and an automatic stop protection system. The two rollers are the primary functional components of the machine; they’re motor-driven through a speed reducer and rotate at a specific speed differential ratio.

Coarse Fiber Separator

The Coarse Fiber Separator is the perfect tool for removing coarse fiber from rubber granules, enhancing the purity of rubber for subsequent powder milling. This device primarily includes a Suction Mouth, Air Volume Adjustment Door, Flexible Pipes, Draught Fan, Body Frame, and Cyclone.

LS Screw Conveyor

The LS Screw Conveyor, specifically designed for conveying rubber granules and powder, serves to link various machines in a line or distribute feed among multiple machines. This machine primarily comprises a motor, speed reducer, conveyance tunnel, screw shaft, hopper, frame, viewing window, splitting motor and valve as well as a discharge outlet.

Rubber Powder Grader

The FJ Rubber Powder Grader uses a high-speed air current to fluidize powder materials in a sealed environment. Under negative air pressure, light and heavy powders are separated, effectively grading different sizes of rubber powders. The main components include a frequency conversion motor, V belt pulley, feeding pipe, bearing bracket, rotor, large impeller, small impeller, adjusting plate, disperse plate and rotary valve.

Rubber Powder Superfine Miller

This product, developed using advanced local and international technology, is extensively used in the production of natural and synthetic rubber as well as plastic powder. Its primary components include a miller, collector, draught fan, cyclone, and control cabinet among others.

PLC Auto Control System

The PLC automatic control system adopts an engineering modular design, integrating PC technology, signal detection and analysis, tracking, frequency conversion, communication technology etc. Combined with modular control technology, it ensures the stability, safety and operational efficiency of the entire production line.

Cooling System

The cooling system uses the principle of water evaporation to cool water heated by machines during operation. It integrates with each machine’s internal cooling systems, ensuring steady, efficient, and safe operation across the entire line. The system primarily includes a water tank, cooling tower, high-pressure pump, outlet pipe, feedback pipe and ladder among other components.

More

Frequently Asked Questions

Get the answers to common questions regarding our Recycling Machine

A Tire Recycling Machine is a device designed to process scrap tires into reusable materials such as crumb rubber, enhancing recycling efforts.

The Tire Recycling Machine uses advanced grinding, shredding, and separation technologies to break down tires into smaller, manageable pieces.

Our Tire Recycling Machine can process various types of tires including passenger, truck, and off-road tires efficiently.

Yes, the Tire Recycling Machine is designed with multiple safety features to protect operators and enhance workplace safety.

The energy consumption is optimized to minimize costs, making our Tire Recycling Machine an efficient choice for businesses.

You can purchase a Tire Recycling Machine directly from our website or contact our sales representatives for further assistance.