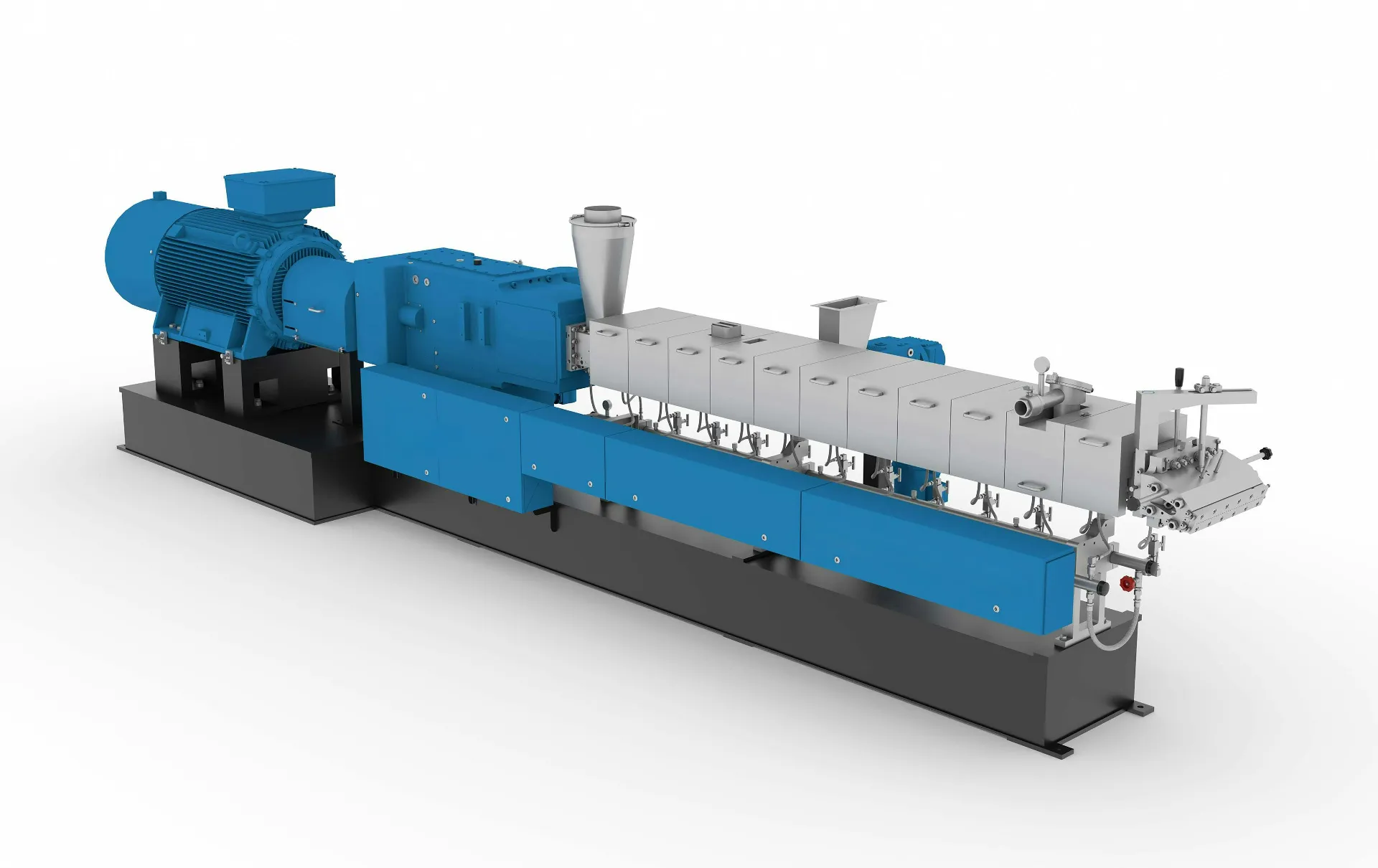

The Twin-Screw Extruder System is a high-performance machine designed for efficient material processing in various industries. It offers superior mixing, compounding, and extrusion capabilities for a wide range of materials.

Main Features Of Double Screw Extruders

Flexibility

The modular “building block” design allows for flexible combination of screw elements to meet material process requirements, ensuring an optimal structure.

Modular Design

The barrel of the co-rotating twin screw extruder is designed with modularity for versatility.

Double Screw Specification

Screws range from Φ16mm to Φ135mm, with various speed and torque designs tailored to diverse customer needs.

Gear Box

The gearbox is available in four sub-series based on torque levels: B (standard), C (medium torque), D (high torque), and G (ultra-high torque). High-torque imported gearboxes and safety torque couplings are also options for enhanced performance and customization.

Self-Cleaning Performance

The co-rotating twin screw extruder features full-mesh screws, providing self-cleaning functionality to prevent material residue and local overheating degradation.

Excellent Mixing and Plasticizing Performance

Finite element analysis is used to optimize screw design, ensuring complete engagement for superior mixing. Thread material is selected based on the material type to achieve optimal results.

Barrel and Alloy Insert Combinations

Adaptable barrel matrix and alloy insert combinations support all material types and simplify maintenance. Various functional barrel elements (e.g., feeding, side feeder, exhaust, liquid filling) expand processing options.

Heating System

Choose from traditional (cast copper, cast aluminum) or modern energy-efficient heaters (infrared, heating rods). Each zone is independently controlled for precise temperature regulation.

Metering

Combine volume metering feeds and weight-loss metering feeders to suit various process requirements. Main and side feeding configurations enhance versatility.

One-Stop Solutions

Comprehensive solutions for specialized materials such as lithium batteries and thermosetting plastics are available.

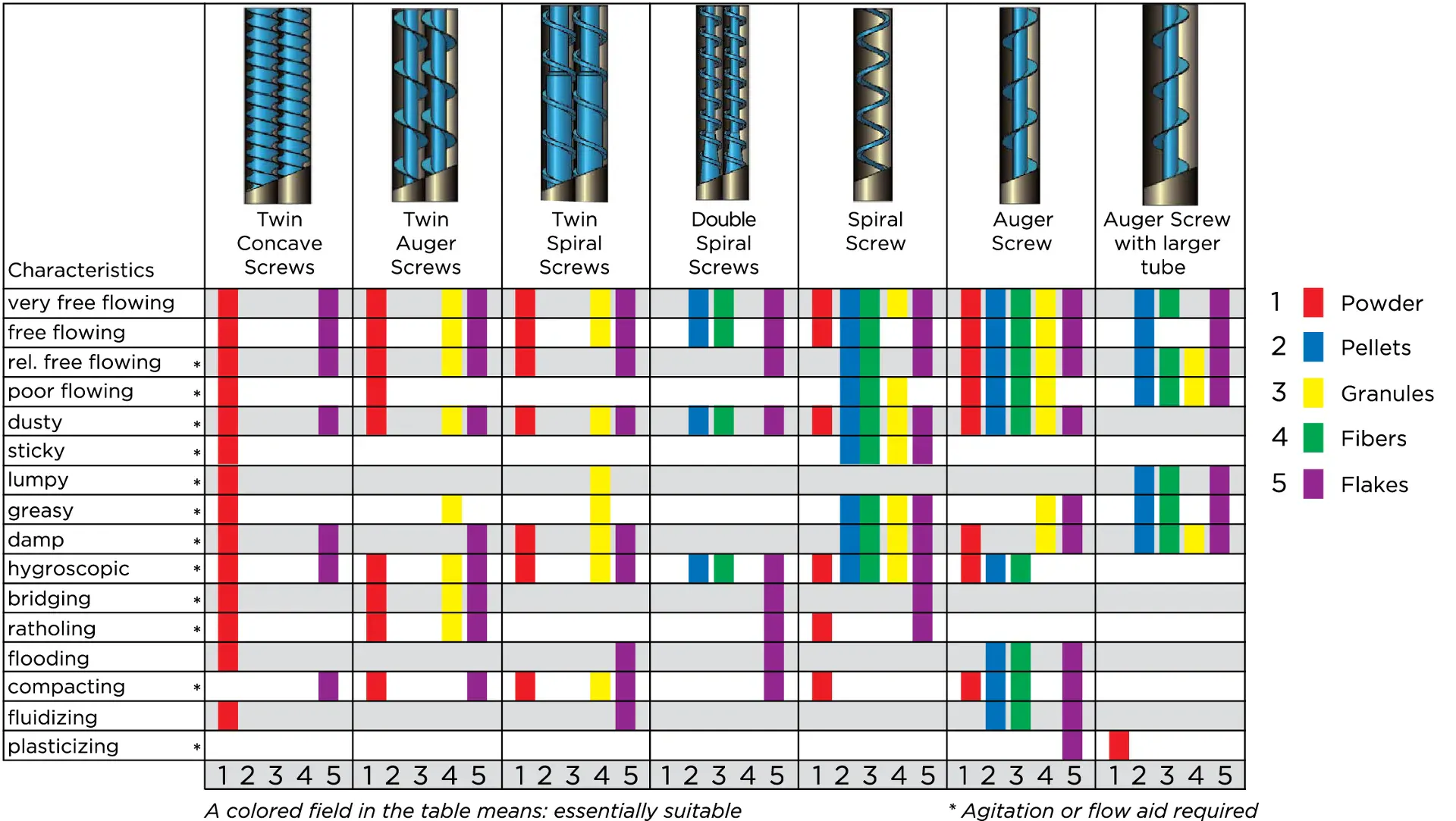

Various Types of Screws

Technical Specifications

| Specification | Value |

|---|---|

| Screw Diameter | 50-150 mm |

| L/D Ratio | 68:1 |

| Max. Screw Speed | 600 RPM |

| Motor Power | 55-450 kW |

| Max. Capacity | 150-2000 kg/h |

Application Fields

Fiber Reinforcement

Enhancing the strength and durability of composite materials through the integration of reinforced fibers for structural applications.

Polymer Blending

Combining different polymers to create customized materials with improved mechanical, thermal, and chemical properties.

Incorporation Of Fibers

Integrating fibers into base materials to enhance flexibility, resilience, and impact resistance in various applications.

Cable Compounds

Specialized formulations designed to improve insulation, conductivity, and durability in electrical and communication cables.

Color Masterbatches

High concentration color masterbatches, flame retardant color masterbatches, degradable polymerized search masterbatches, powder coatings and other applications.