Centrifugal dryers, often used in industrial settings for drying various materials, operate on a simple yet effective principle. These devices are crucial in processes where rapid and efficient drying is required, such as in the textile, chemical, and pharmaceutical industries. Here, we delve into how these machines function, why they are effective, and what makes them indispensable in industrial applications.

What is a Centrifugal Dryer?

A centrifugal dryer is a machine that uses centrifugal force to remove moisture from materials. Unlike traditional drying methods that might use heat or air flow, centrifugal dryers rely on the physics of spinning to extract water.

How Does It Work?

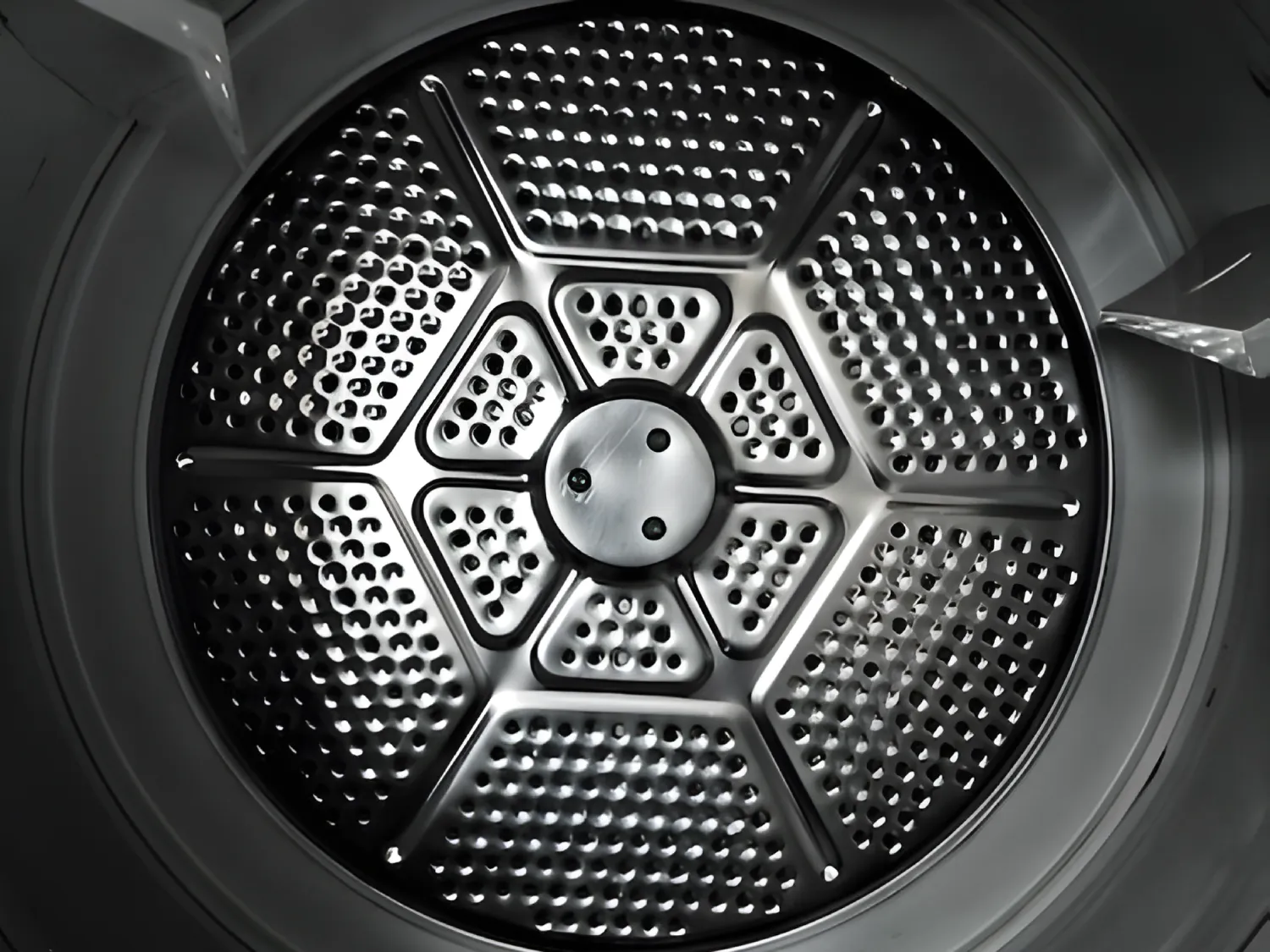

- Loading the Material: The process begins by loading the material, often in a perforated basket or drum. This could be anything from fabric in a textile plant to sludge in a waste management facility.

- Key Point: The material must be uniformly distributed to ensure even drying.

- Spinning: Once loaded, the drum starts to rotate at high speeds:

- Centrifugal Force: As the drum spins, the centrifugal force pushes the water or moisture content away from the material towards the walls of the drum.

- Speed: Typically, the drum can reach speeds where the force generated is many times that of gravity, sometimes up to 1000 G-forces.

- Example: In a study by Rumtoo, Inc., it was found that at speeds over 2000 RPM, 90% of the moisture from cotton fabric could be removed in under 5 minutes.

- Water Removal:

- Perforations: Water is forced through small holes or perforations in the drum into an outer casing, from where it is drained away.

- Efficiency: This method ensures that water is not just evaporated but mechanically separated, which can be more energy-efficient depending on the application.

- Unloading: After the spinning cycle, the rotation slows down, and the now-dried material is removed.

- Note: For delicate materials, the speed and duration of spinning might be adjusted to prevent damage.

Why Use Centrifugal Dryers?

- Speed: They provide a rapid drying solution, crucial for industries where time is a significant cost factor.

- Energy Efficiency: By mechanically removing water, they can be more energy-efficient than thermal drying methods for certain applications.

- Material Preservation: Lower temperatures mean less risk of thermal degradation of sensitive materials.

- Versatility: Can handle a variety of materials from different industries.

Applications and Considerations

- Textiles: Used for drying clothes in industrial laundries at speeds that protect fabric integrity yet remove moisture efficiently.

- Chemicals: Useful for separating solvents from solid products.

- Food Industry: For dewatering fruits or vegetables where texture preservation is key.

- Maintenance: Regular maintenance is crucial to ensure the drum’s balance and the integrity of the perforations, which directly affect the efficiency of the dryer.

Conclusion

Centrifugal dryers stand out for their efficiency and effectiveness in industrial drying processes. By understanding the principles behind their operation, businesses can better decide when to implement these machines within their operations. Whether for reducing drying time, lowering energy costs, or preserving material quality, centrifugal dryers offer a robust solution tailored to meet the rigorous demands of modern industry.