Ideal for recycling and waste management, this durable machine is engineered to handle various plastic materials, ensuring optimal performance and minimal downtime. Perfect for industrial applications, our crusher enhances productivity while contributing to a sustainable environment.

Key Features of Universal Plastic Shredders

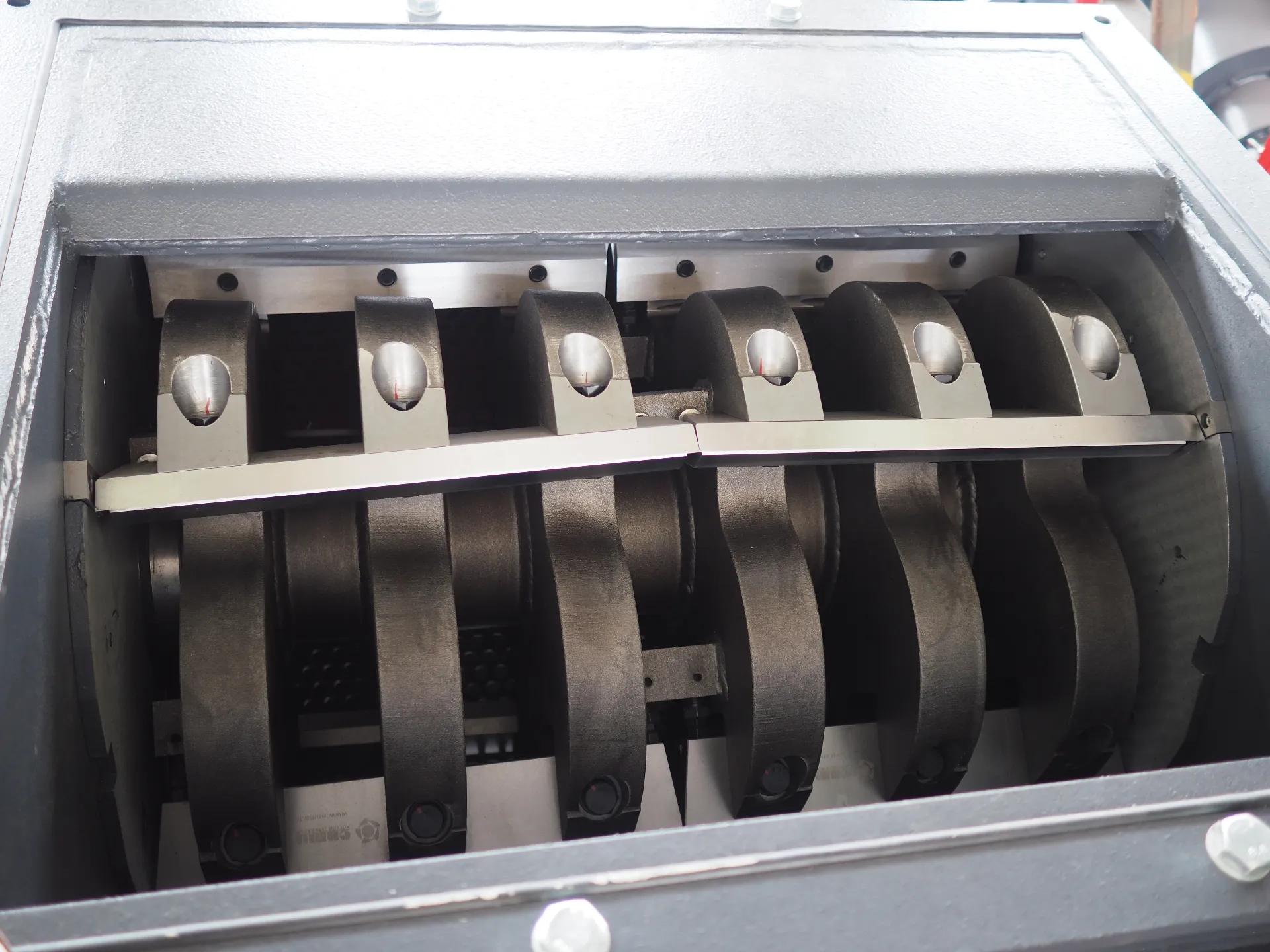

- Robust Blade Design

High-quality shredders use hardened steel blades with heat-treated edges. These blades cut through thick plastics, films, and rigid containers without frequent sharpening. Some models feature reversible blades, doubling their lifespan and minimizing downtime. - High Torque Motors

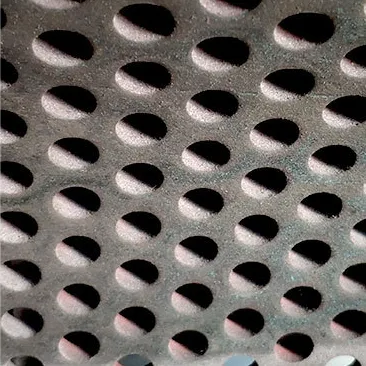

Motors with 15–50 HP power ratings handle heavy loads consistently. This ensures smooth processing of mixed materials like HDPE containers, PET films, or polypropylene woven bags, even in continuous operations. - Adjustable Screen Meshes

Interchangeable screens (10–25 mm) control output size, making shredded plastic ideal for extrusion, injection molding, or direct resale. This adaptability caters to diverse recycling goals. - Safety & Noise Control

Modern shredders include emergency stop buttons, overload protection, and noise-dampening enclosures (under 85 dB). These features protect operators and comply with workplace safety regulations.

Technical Parameters

| Model | Feeding Port (cm) | Motor Power (kW) | Rotor Blades | Fixed Blades | Screen Mesh Aperture (cm) | Rotor Diameter (mm) | Output Capacity (kg/h) |

|---|---|---|---|---|---|---|---|

| RTM600 | 600×300 | 30 | 6 | 2 | 10-25 | Φ500 | 300-500 |

| RTM800 | 800×400 | 45 | 6 | 2 | 10-25 | Φ600 | 600-800 |

| RTM1000 | 1000×500 | 75 | 10 | 4 | 10-25 | Φ600 | 800-1000 |

| RTM1200 | 1200×600 | 90 | 10 | 4 | 10-25 | Φ800 | 1000-1500 |

| RTM1400 | 1400×800 | 110 | 10 | 4 | 10-25 | Φ800 | 1500-2000 |

Maintenance Tips for Longevity

- Daily: Inspect blades for wear and clear debris from the cutting chamber.

- Monthly: Lubricate bearings and check motor alignment.

- Annual: Replace worn screens and belts, and recalibrate safety sensors.

Inquire Now