Optimize Your Recycling Process with Advanced Waste Plastic Film Shredding Machine

In today’s eco-conscious world, managing plastic waste efficiently is paramount. For businesses looking to enhance their recycling processes, investing in a state-of-the-art waste plastic film shredding machine can be a game-changer. This article explores the key features and performance advantages of an advanced shredding machine designed to meet the demands of modern recycling operations.

High-Efficiency Shredding with Continuous Feed

One of the standout features of this waste plastic film shredding machine is its innovative material silo design, which enables a complete cycle of movement. This allows for unrestricted feeding, ensuring that materials are shredded without jamming, thus achieving high shredding efficiency. This continuous feed system not only optimizes operations but also enhances throughput, making it an ideal solution for facilities dealing with large volumes of plastic film waste.

Enhanced Productivity with Custom-Made Main Shaft

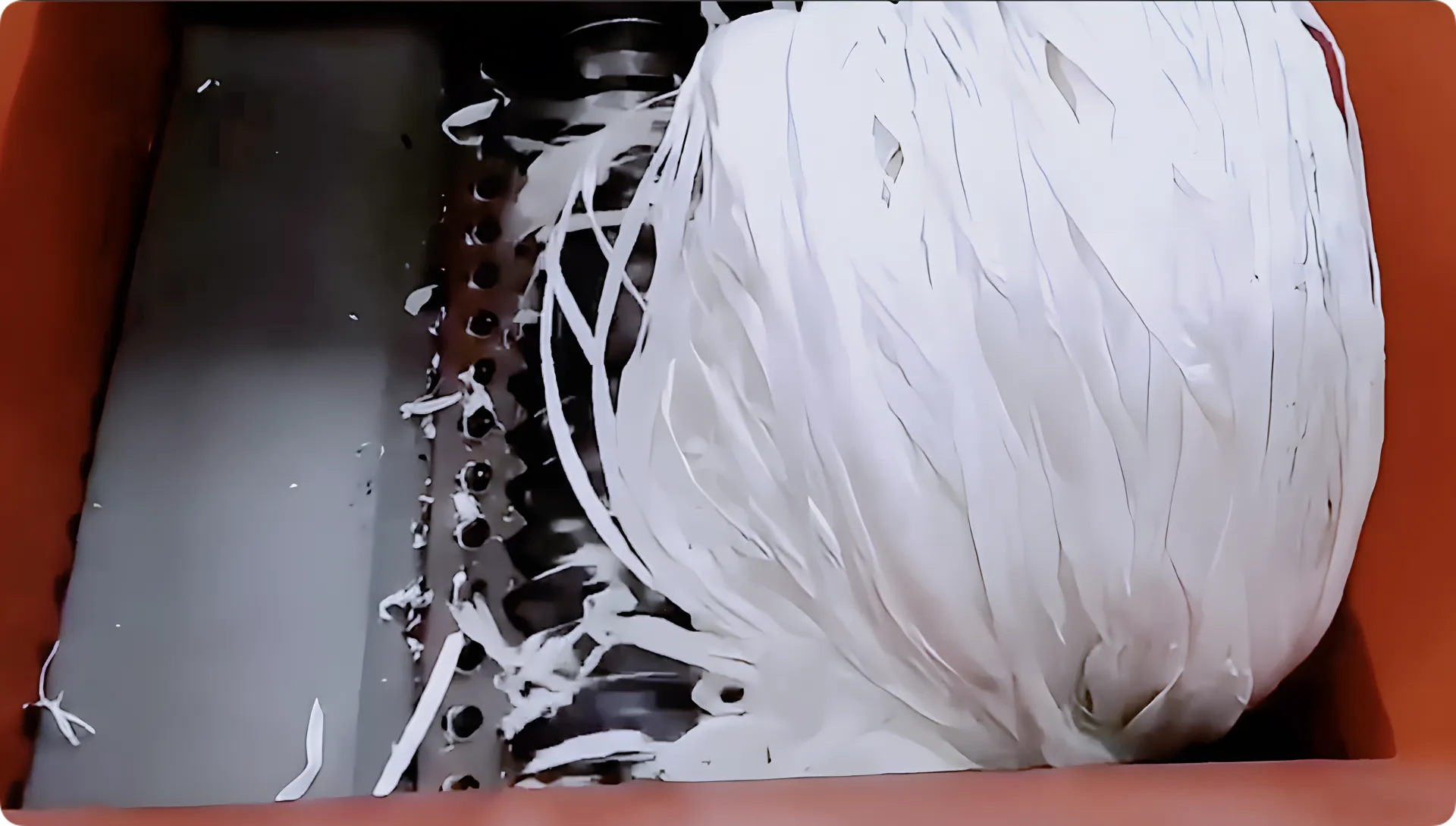

The shredder’s main shaft is custom-made with a large rotation diameter, providing a significant shredding contact surface. This unique design increases the interaction between the material and the shredding mechanisms, thereby boosting productivity. Whether you’re processing industrial quantities of waste or handling varied materials, the large-diameter shaft ensures consistent, efficient shredding.

Vibration Reduction and Component Protection

To further enhance its performance, the shredding machine incorporates couplings in its transmission parts. This strategic design choice helps in reducing vibration, which not only protects the main shaft and the reducer but also ensures that there is no loss of force during operation. By minimizing vibration, the machine extends the lifespan of critical components and maintains consistent performance over time.

Effective Material Cutting and Reduced Maintenance

Equipped with a fixed knife at both the top and bottom of the main shaft, the shredder effectively cuts materials without causing entanglement around the shaft. This design ensures that the shredded pieces are small and manageable, facilitating easier handling and processing downstream. Moreover, the reduction of material wrap-around the shaft significantly lowers the maintenance required, keeping the machine running smoothly with less downtime.

Automated and Safe Operation with PLC Control System

Automation is at the heart of this shredding machine. Featuring an advanced electronic control system with PLC programming, it includes functions such as start, stop, forward, reverse, and automatic overload protection. This automation not only ensures stable and safe operation but also reduces the need for manual intervention, thereby saving labor costs. The user-friendly interface and programmable controls make it easy for operators to manage the shredding process efficiently and safely.

Specification

| Shredder Model | Shaft Diameter (mm) | Moving Knife Qty. (pcs) | Fixed Knife Qty. (pcs) | Maximum Capacity (kg/h) | Motor Power (KW) | Feeding Mouth Size (L x W) (mm) | Host Weight (kg) | Dimensions (L x W x H) (mm) |

|---|---|---|---|---|---|---|---|---|

| RTM-L2455 | 300 | 24 | 2 | 400 | 22 | 800 x 1300 | 3600 | 3250 x 1500 x 2350 |

| RTM-L3063 | 300 | 30 | 2 | 550 | 30 | 900 x 1300 | 4000 | 3250 x 1750 x 2350 |

| RTM-L3980 | 350 | 39 | 2 | 750 | 45 | 1100 x 1500 | 6000 | 4150 x 1900 x 2450 |

| RTM-L36100 | 400 | 36 | 2 | 1200 | 55 | 1300 x 1800 | 8000 | 4700 x 2550 x 2650 |

| RTM-L42120 | 400 | 42 | 2 | 1500 | 75 | 1500 x 1900 | 9500 | 5350 x 2850 x 2760 |

| RTM-L64160 | 500 | 64 | 4 | 5000 | 132 | 2200 x 2200 | 18000 | 5900 x 3050 x 2960 |

Conclusion

Investing in a waste plastic film shredding machine with these advanced features represents a strategic decision for businesses aiming to improve their recycling efficiency and operational productivity. With its combination of continuous feeding, custom-made components, vibration reduction, effective material cutting, and automation, this shredder is designed to meet the challenges of modern waste management and recycling facilities. Embrace technology to make your recycling process more efficient, safe, and cost-effective.